Nylon features and preparation method of aluminum-plastic composite film using nylon with features

An aluminum-plastic composite film, nylon technology, used in applications, household appliances, flat products, etc., can solve problems such as peeling, poor adhesion of matte layers, etc., to reduce the amount of hydrophobic agents, and to achieve excellent matte coating adhesion. , the effect of matte coating adhesion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

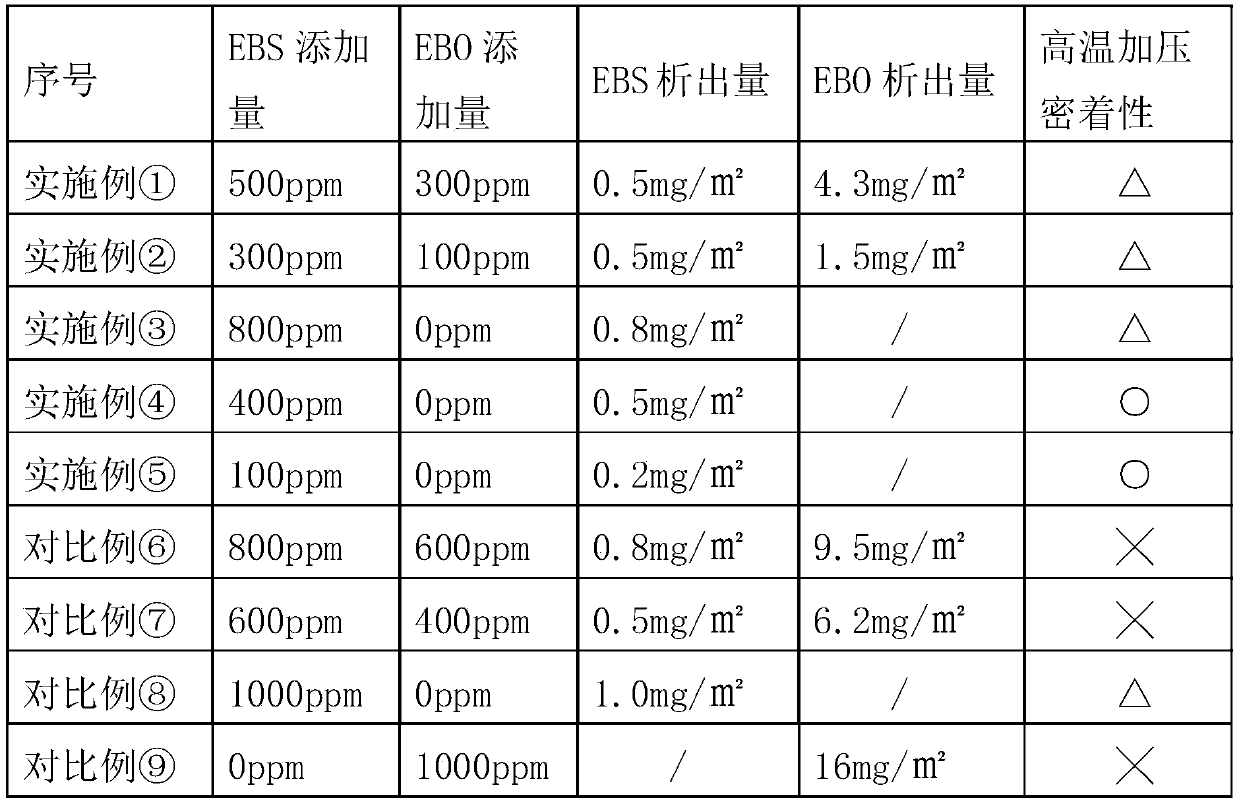

[0040]According to the characteristic Ny of the above hydrophobic treatment, the aluminum-plastic film for black soft pack lithium battery was made and evaluated. Among them, EBS was selected as the high melting point hydrophobic agent A, and EBO was selected as the low melting point hydrophobic agent B, as shown in the following table 1:

[0041]

[0042] Table 1

[0043] Note:

[0044] 1. ○: No shedding; △: Incidence rate: <5%; ╳: Incidence rate ≥ 5%;

[0045] 2. Before the measurement of the amount of precipitation, the nylon membrane should be subjected to high temperature treatment at 80°C for one day.

[0046] 3. Evaluation of adhesion under high temperature and pressure: Cut the black aluminum-plastic film into 75*50mm size samples, attach a protective film on the matte layer of the black aluminum-plastic film (the total thickness of the protective film is 72 μm, the thickness of the adhesive layer is 10 μm, acrylic adhesive, Standard adhesion force 30g), 2kgf roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com