A heavy oil contact cracking method and a heavy oil contact cracking device

A technology of contact cracking and heavy oil, which is applied in chemical instruments and methods, petroleum industry, chemical/physical processes, etc. It can solve the problems of poor quality heavy oil that is difficult to crack and is not suitable for processing, so as to shorten the residence time, avoid cracking and increase the yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] This example is used to illustrate the heavy oil contact cracking method of the present invention.

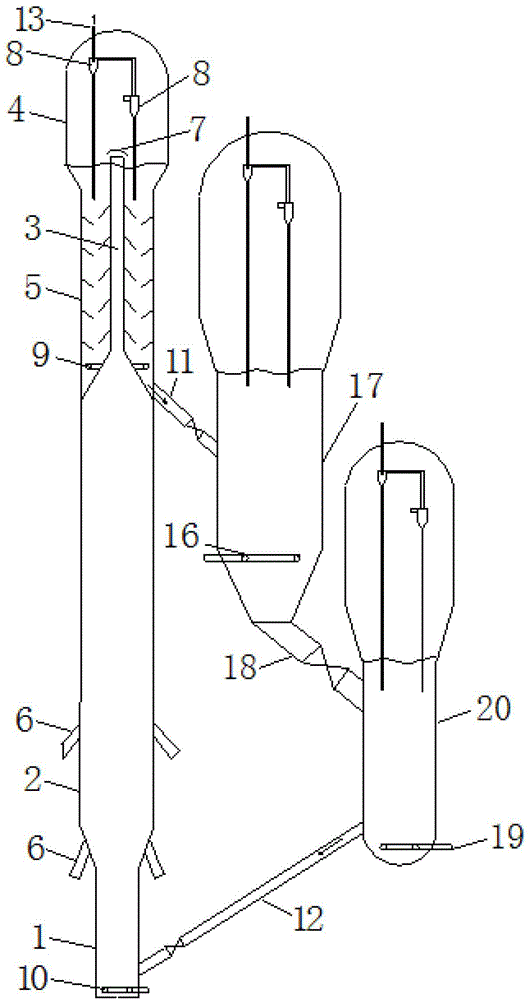

[0088] The heavy oil contact cracking unit used in this example is as follows: figure 1 As shown, in the heavy oil contact cracking unit, the bed reaction section is provided with two layers of feed nozzles 6, and each layer is provided with 6 feed nozzles, which are evenly distributed along the radial circumference of the reactor wall. The first layer of nozzles is located in the bed In the upper middle of the expanded diameter section between the layer reaction section 2 and the pre-lift section 1, the second layer of nozzles is located at the lower third of the bed layer reaction section 2, and the radial cross-sectional projection positions of the upper and lower layers of nozzles are evenly distributed; The height-to-diameter ratio of bed reaction section 2 is 3; the diameter ratio of bed reaction section 2 to riser reaction section 3 is 3:1; the diameter ratio of b...

Embodiment 2

[0098] This example is used to illustrate the heavy oil contact cracking method of the present invention.

[0099] The heavy oil contact cracking unit used in this example is as follows: figure 1 As shown, in the heavy oil contact cracking unit, the bed reaction section is provided with two layers of feed nozzles 6, and each layer is provided with 6 feed nozzles, which are evenly distributed along the radial circumference of the reactor wall. The first layer of nozzles is located in the bed In the upper middle of the expanded diameter section between the layer reaction section 2 and the pre-lift section 1, the second layer of nozzles is located at the lower third of the bed layer reaction section 2, and the radial cross-sectional projection positions of the upper and lower layers of nozzles are evenly distributed; The height-to-diameter ratio of bed reaction section 2 is 3; the diameter ratio of bed reaction section 2 to riser reaction section 3 is 5:1; the diameter ratio of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com