Method for smelting weather resistant steel through high-phosphorus-content steel discharging by converter

A technology for steel smelting and weathering steel, which is applied in the field of converter high-phosphorus tapping and smelting weathering steel, can solve problems such as waste and increase the cost of ferrophosphorus alloy, and achieve the effects of low basicity, reduced ferrophosphorus consumption and high phosphorus content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] To produce 10 furnaces of phosphorus-containing weathering steel, the same dephosphorization converter is used for continuous smelting, and the previous furnace smelting only dephosphorizes but does not decarburize.

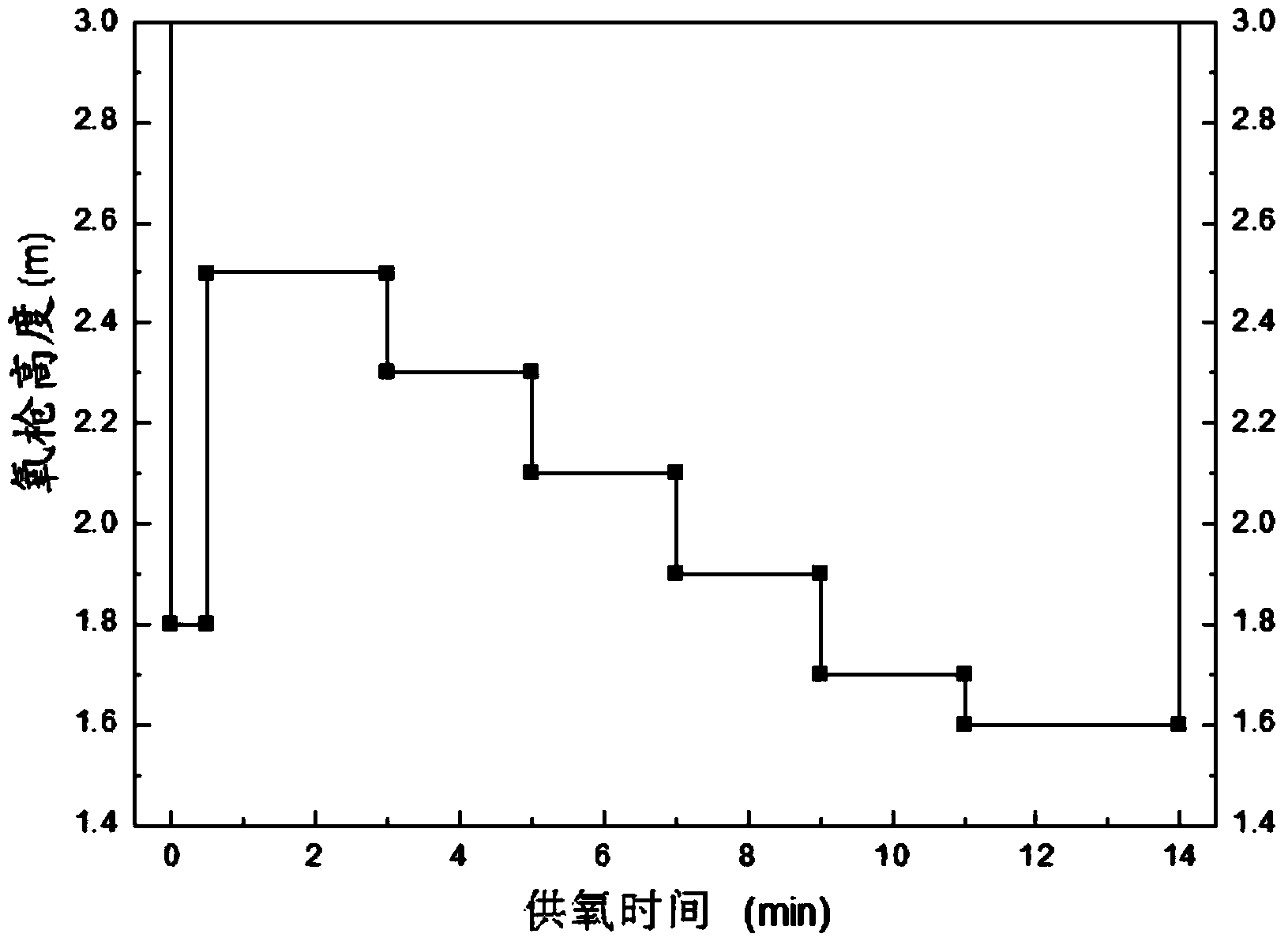

[0034] Steel scrap is added to the iron converter, and the molten iron is desulfurized by KR and then mixed into the converter; 3-5 tons of slag from the previous furnace is retained, and 4-6 tons of light-burned dolomite is added within 2 minutes before blowing to form slag, and the amount of oxygen blowing in the middle and late stages of blowing reaches When 70%-80%, add raw burnt dolomite and ore to cool down, the ratio of ore and raw burnt dolomite is 1:1, and the total amount is within 8 tons; the blowing gun position of the converter blowing is 2.5m, and the gun is lowered five times , the terminal gun position is 1.6m; the steel is tapped after the converter terminal is controlled. Among them, the blowing process oxygen lance position diagram can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com