Roof waterproof and thermal insulation integrated coating and its construction method

A construction method and coating technology, applied to roofing, roof insulation materials, buildings, etc., can solve problems such as cost control, unfavorable structural safety, self-heavy upper part, and damage to the waterproof layer, etc., to achieve favorable structural safety, light weight, The effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

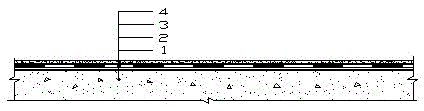

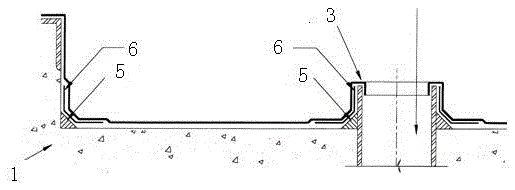

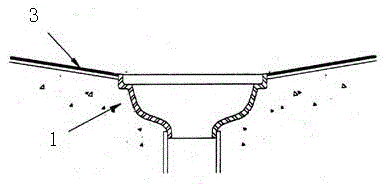

[0023] 1. The base layer should be cleaned before construction. The spraying construction should be divided into areas in advance and completed area by area. The polyurea spray coating with a thickness of 1.5-2mm is generally completed in 3-4 times.

[0024] 2. Stir the R bucket with a pneumatic agitator for more than 30 minutes before spraying. Turn on the pipeline heater before spraying, and after the temperature of the pipeline heater reaches the set temperature, set other host parameters, and then carry out spraying construction. During construction, the two pumps equipped with the main engine are inserted into the barrels containing A and R raw materials respectively, and the raw materials are pushed into the mixing chamber of the spray gun by the high pressure generated by the main engine, mixed, atomized and sprayed out. When it reaches the base layer, the coating is almost gelled, and after 5-10 seconds, the coating is completely cured.

[0025] 3. When spraying, spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com