Rotation angle detecting device and rotary drive unit by use thereof

A technology of rotation angle detection and rotation angle, which is applied in the field of rotation angle detection device and rotation drive unit, and can solve problems such as wrong detection of rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

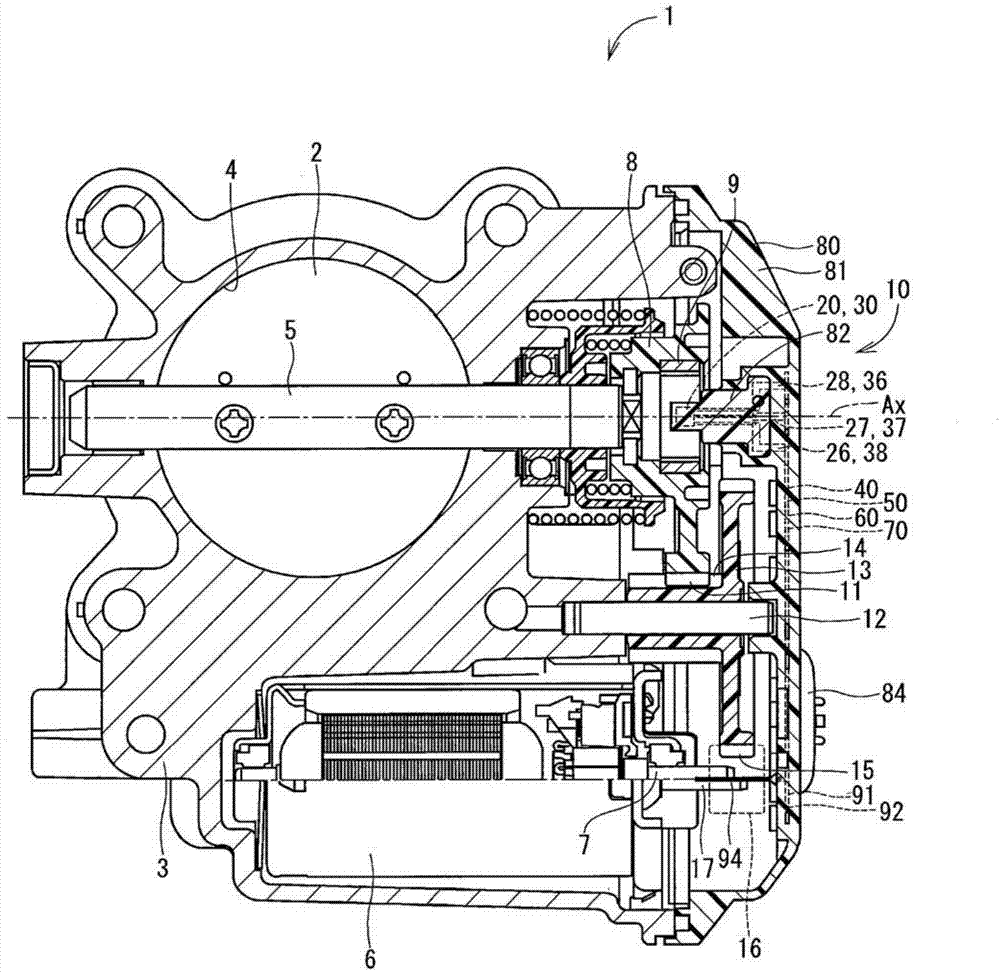

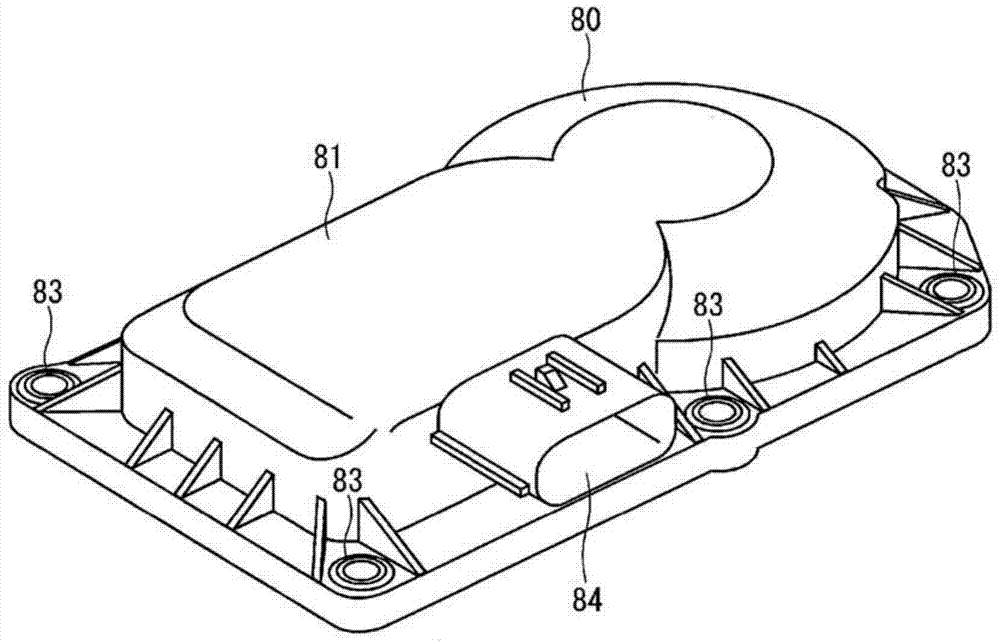

[0019] The rotation angle detection device in the first embodiment and the rotation driving unit to which it is applied are shown in figure 1 middle. The rotation drive unit 1 is used to rotate, for example, a throttle valve 2 provided in an intake system (intake system) of a vehicle. The rotary drive unit 1 includes a housing 3 , a valve shaft 5 , a motor 6 and a rotation angle detection device 10 .

[0020] The housing 3 is formed of metal such as aluminum, and includes therein a passage 4 having a substantially cylindrical shape. The channel 4 constitutes an intake channel for guiding intake air into the internal combustion engine. The valve shaft 5 is formed in a rod shape and is arranged rotatably relative to the housing 3 so that the shaft 5 is substantially perpendicular to the channel axis of the channel 4 .

[0021] The throttle valve 2 is formed in a substantially circular plate shape, and it is attached to a valve shaft 5 by, for example, a screw member. Theref...

no. 2 example )

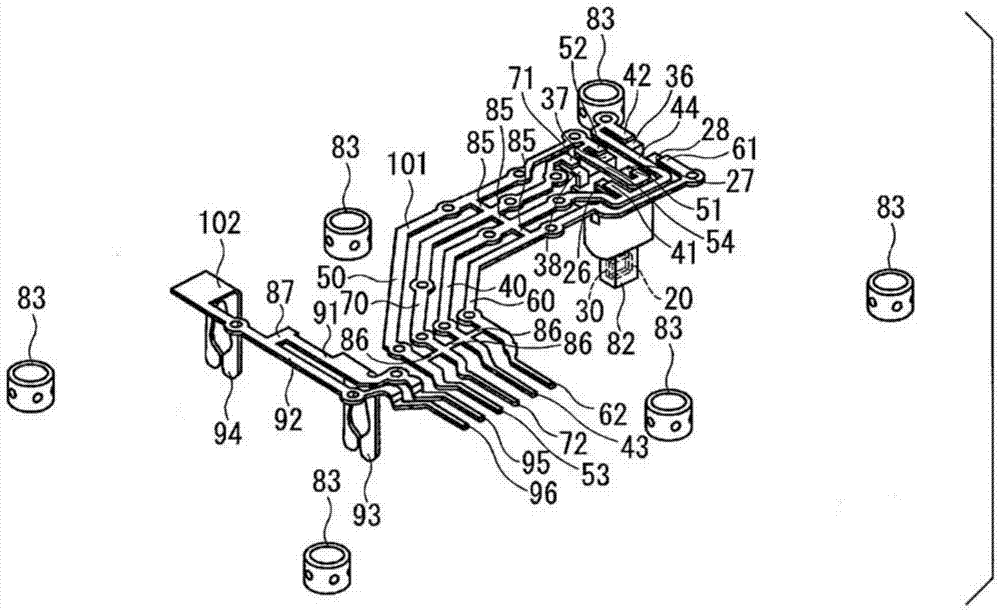

[0065] The rotation drive unit and the rotation angle detection device in the second embodiment are partially shown in Figure 5 and Figure 6 middle. The second embodiment differs from the first embodiment in the shape of the ground line of the rotation angle detection device.

[0066]In the second embodiment, the ground line 50 includes a linear connection portion 55 instead of the bypass wiring portion 54 of the first embodiment. The linear connection portion 55 is linearly formed to connect the first ground portion 51 and the second ground portion 52 together. Therefore, the first ground portion 51 and the second ground portion 52 are linearly connected. The configuration of the second embodiment is similar to that of the first embodiment except for the above-mentioned points.

[0067] As described above, in the current embodiment, the first ground portion 51 and the second ground portion 52 are connected by the linear connection portion 55 . Therefore, if heat is appl...

no. 3 example )

[0069] The rotation drive unit and the rotation angle detection device in the third embodiment are partially shown in Figure 7 middle. The third embodiment differs from the first embodiment in the arrangement of the first IC package and the second IC package, the shape and arrangement of wiring, and the like.

[0070] In the third embodiment, the first IC package 20 and the second IC package 30 are insert molded by the main forming body 82, wherein one surface 251 of the sealing body 25 in the first IC package 20 and the sealing body in the second IC package 30 The other surface 352 of the body 35 is in contact. Therefore, the distance from the rotation axis Ax to the first magnetic detection element 21 and the second magnetic detection element 31 is long compared with the first and second embodiments. However, both the first magnetic detection element 21 and the second magnetic detection element 31 may be arranged at positions relatively close to the rotation axis Ax.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com