Thermal image analysis device and thermal image analysis method

A technology of image analysis and analysis area, applied in the field of thermal image analysis devices, can solve the problems of cumbersome analysis mode, inconvenient use, difficult diagnosis and judgment, etc., to achieve the standardization and accuracy of reference images and analysis areas, and ensure correctness and convenience. , automatic or simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

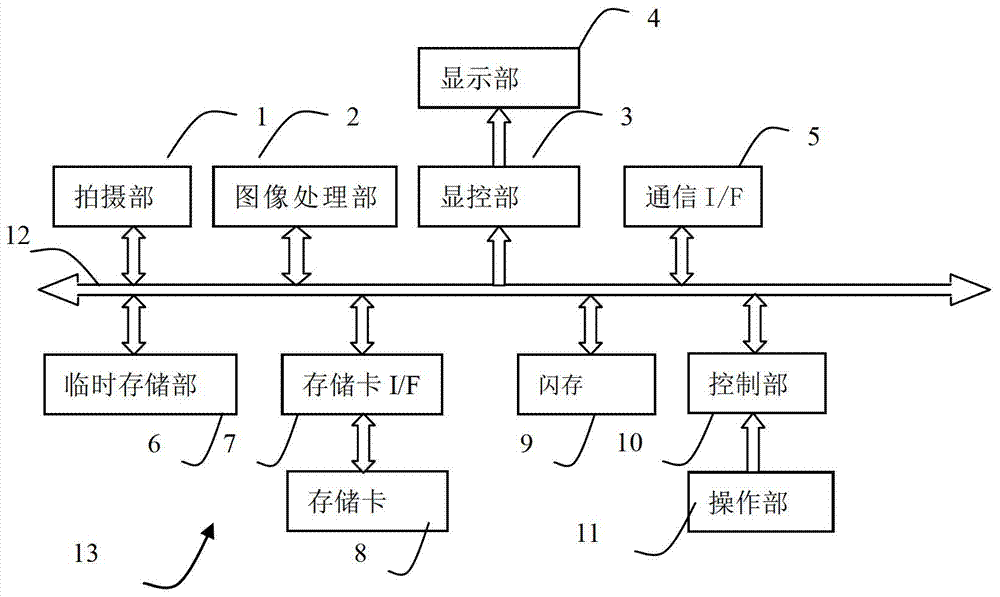

[0076] The image processing unit 2 is used to perform specified processing on the thermal image data obtained by the shooting unit 1. The processing of the image processing unit 2, such as correction, interpolation, false color, synthesis, compression, decompression, etc., is converted into a suitable display, Handling of data such as recording. The image processing unit 2 is used to perform prescribed processing on the thermal image data captured by the imaging unit 1 to obtain image data of infrared thermal images. For example, the image processing unit 2 performs non-uniformity correction on the thermal image data acquired by the imaging unit 1 , interpolation and other prescribed processing, perform pseudo-color processing on the thermal image data after the prescribed processing, and obtain image data of infrared thermal images; an implementation of pseudo-color processing, for example, according to the range or AD value of thermal image data (AD value) The setting range ...

Embodiment 1

[0232] In Embodiment 1, the analysis process is always carried out, and the analysis results are constantly updated, and the analysis results are displayed when the notification instruction from the user is received; but it can also be configured to perform the analysis only when the analysis key is pressed; or the analysis results The display can also be shown and refreshed all the time.

[0233] In addition, as shown in Figure 1703, the position parameters of the reference image can also be adjusted to match the thermal image IR1 of the subject in the infrared thermal image. Preferably, the reference image position setting part and the analysis area position setting part can The adjustment operation is performed to change at least one of the position, size, and rotation angle of the reference image and the analysis area in the infrared thermal image, and keep the prescribed positional relationship between the two unchanged. For example, when one of them is adjusted, the othe...

Embodiment 2

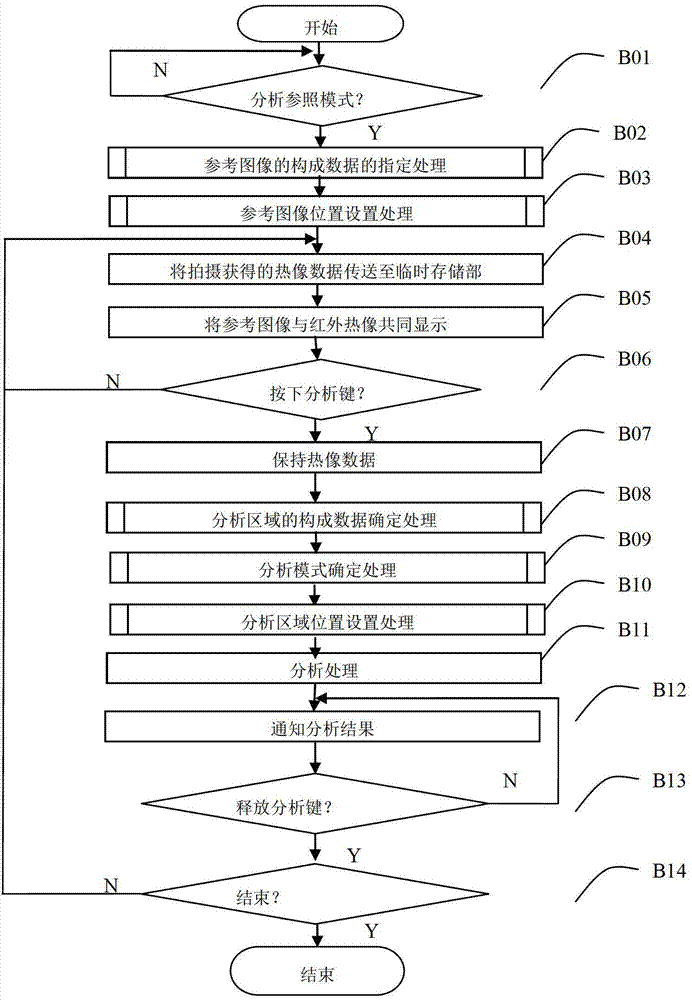

[0236] Embodiment 2 is a thermal imaging device 13 having the same structure as that shown in Embodiment 1. An analysis control program different from that of Embodiment 1 is stored in the flash memory 9. In response to an analysis instruction from a user, the thermal image data will be frozen, displayed and maintained. , and perform analysis to obtain the analysis result; and, store in the flash memory 9 such as Figure 4 memory contents as shown, and as Figure 13 configuration shown.

[0237] refer to Figure 23 To illustrate the control flow.

[0238] In step B01, the control unit 10 continuously monitors whether the analysis and reference mode is selected, and if so, proceeds to step B02.

[0239] In step B02, the control unit 10 performs a process of specifying the constituent data of the reference image. see details Figure 18 Steps S101-S107 in.

[0240] In step B03, the control unit 10 performs setting processing of the position parameters of the reference image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com