Mask repair method

A repairing method and a technology of a mask plate, which are applied in the direction of photolithography, optics, instruments, etc. on the pattern surface, can solve the problems of low efficiency and poor effect of the repairing method, so as to prevent the defects from becoming serious, save production costs, reduce The effect of dealing with risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

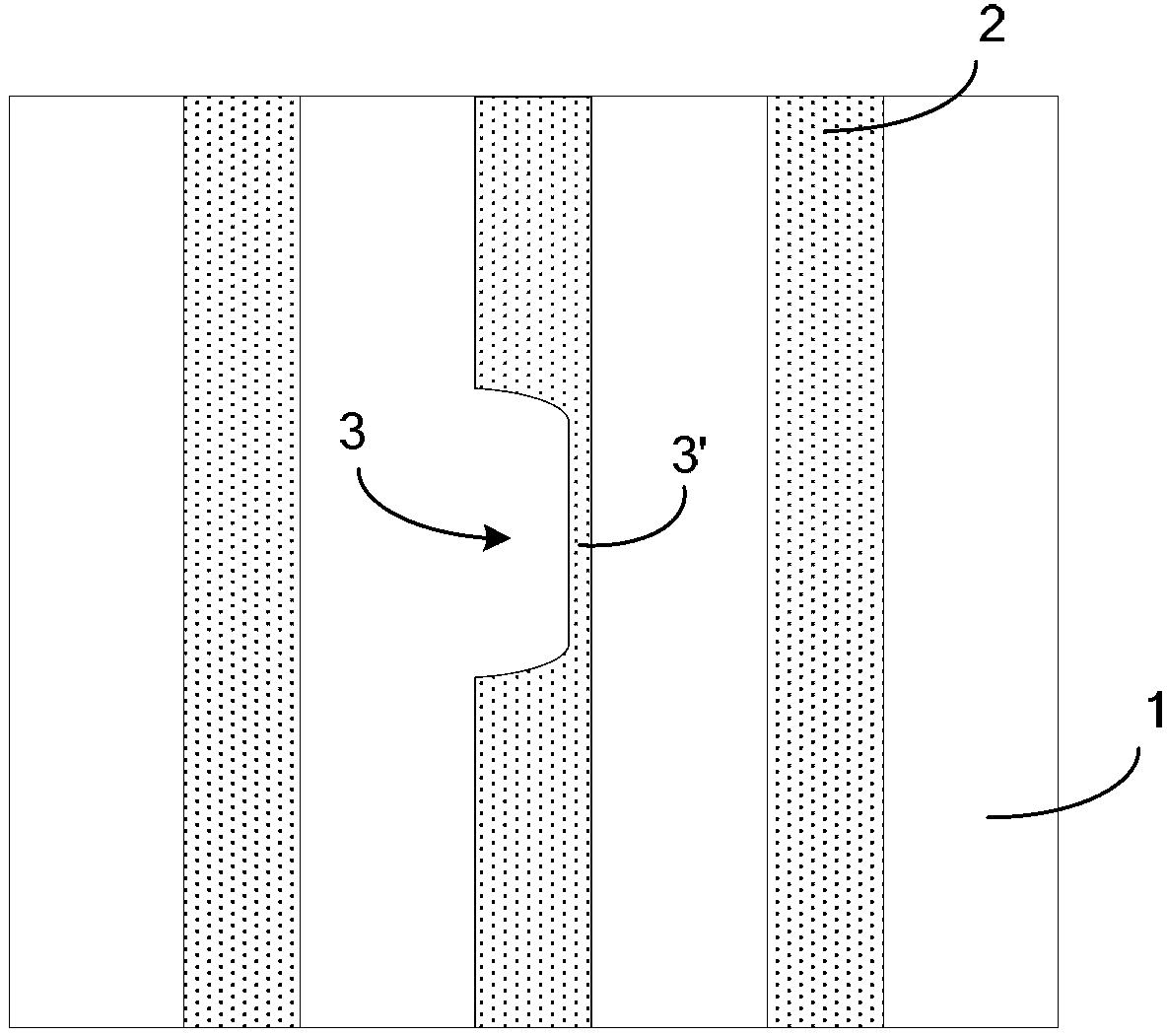

[0035] Please refer to figure 2 , the defective mask includes a substrate 1 and a patterned light-shielding layer 2, as shown in the figure, this mask is a line (Line) mask, which is used in the semiconductor manufacturing process metal layer. E.g figure 2 The line in the middle has a pattern missing 3. In this case, it must be repaired, otherwise after the photolithography process, figure 2 The narrow line part 3' corresponding to the lack of 3 in the figure shown in the figure cannot be formed on the silicon wafer, and then there is a fracture phenomenon, forming a dead unit (dead die).

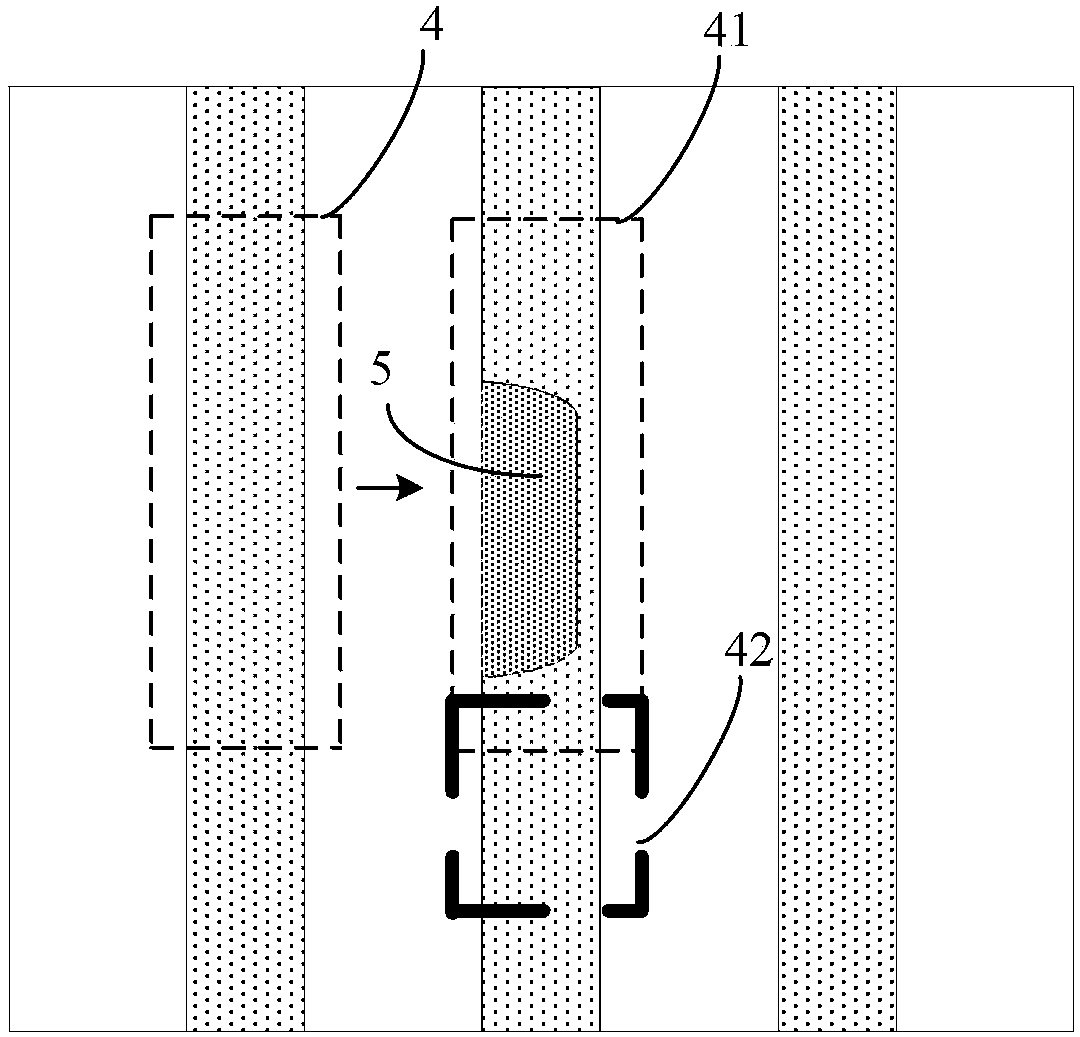

[0036] Please refer to image 3 , copy a normal region 4 from a nearby pattern with the same structure to the missing part of the defect region to obtain the region 5 to be filled, the effective size of the normal region 4 should be greater than the area of the missing pattern, so that the area to be filled can be accurately obtained area 5. During copying, the copied normal area ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the masks processed are different, please refer to Figure 7 , the defective mask is a square mask, which is used to form a through hole (contact) on a silicon wafer. As shown in the figure, the normal area is a pattern 8, and in this embodiment, the middle defective area has a pattern 8'.

[0043] Please refer to Figure 8 , using the same method as in Embodiment 1, copying the normal area (the pattern 81 is selected here) to the defect area to obtain the area 9 to be filled. Likewise, the replicated normal area 81' should match the surrounding normal area. For example, the position of the copied normal region 81 ′ can be positioned based on the straight lines x and y formed by the graphic edges of the surrounding normal regions.

[0044] Please refer to Figure 9 , using FIB to deposit naphthalene into the area to be filled to form the repaired area 10 . For the same reason, residual defects 11 are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com