Chemical reaction demonstration device

A technology of chemical reaction and demonstrator, applied in the field of chemistry teaching aids, can solve the problems of difficult fixing of electrodes, unsatisfactory experimental results, inconvenient glass rod stirring, etc., and achieves accurate and obvious experimental phenomena, fast and accurate conductivity, and experimental results. complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

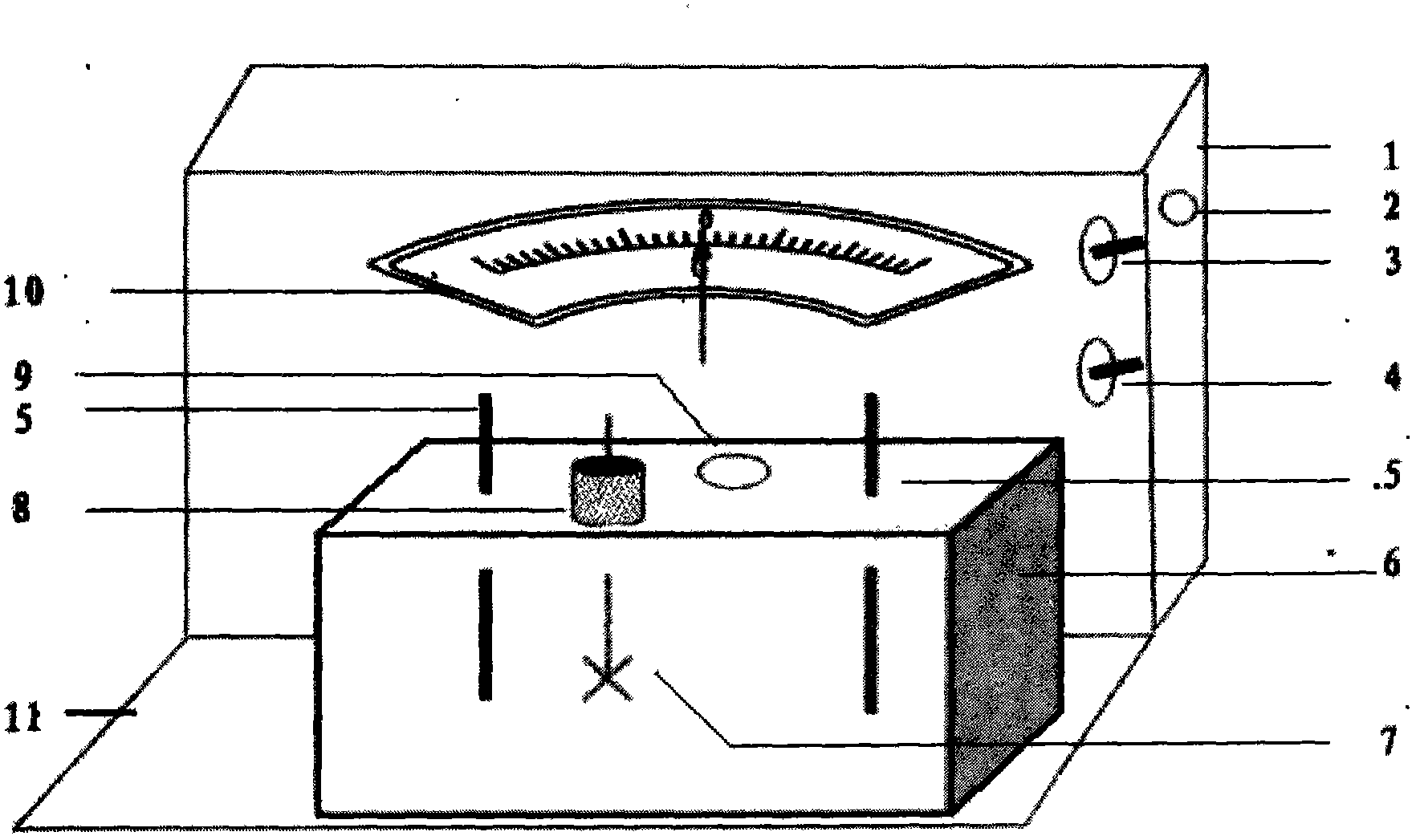

[0009] Such as figure 1 As shown, the technical solution of the present invention is: a chemical reaction essence demonstrator, including side plate 1, DC power input jack 2, main power switch 3, micro-motor switch 4, carbon rod 5, solution tank 6, electric stirring Glass rod 7, micro motor 8, round hole 9, ammeter 10, base plate 11, characterized in that: the side plate is fixed on the base plate 11, and the side plate 1 is provided with a DC power input jack 2, a main power switch 3, Micro-motor switch 4, ammeter 10, described solution tank 6 is a cuboid, two identical carbon rods 5 are fixed on the solution tank 6 cover, in the middle of solution tank 6, be provided with the electric stirring bar 7 driven by micro-motor 8, so The micro motor 8 is embedded in the middle of the solution tank 6 cover, and the solution tank 6 cover is provided with a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com