Double-edge structure speed regulating permanent magnet coupler

A permanent magnet coupler and speed regulation technology, applied in permanent magnet clutches/brakes, electrical components, electromechanical devices, etc., can solve the problems of low starting torque of induction motors and expensive motor controllers, and achieve easy operation, Simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

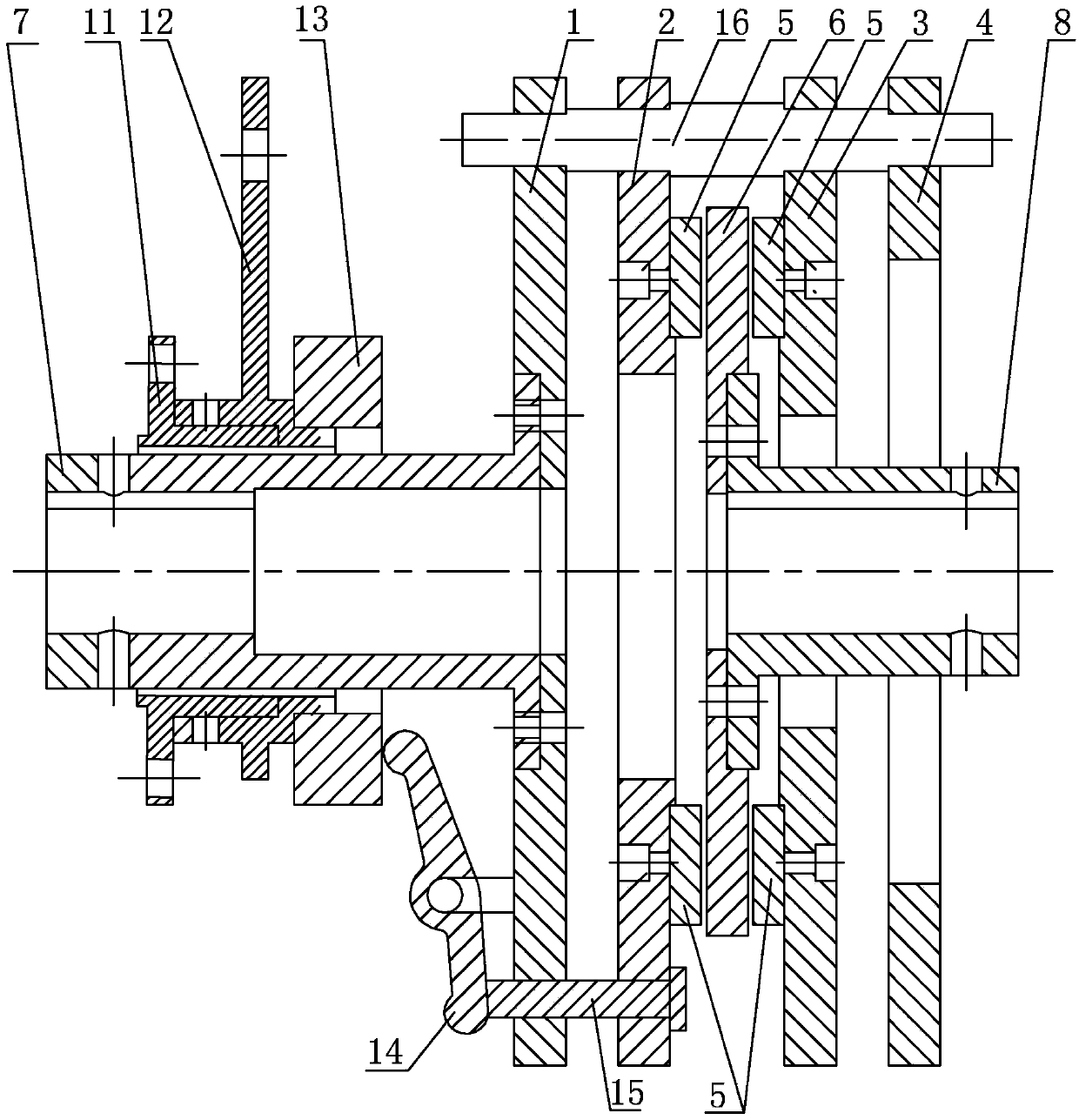

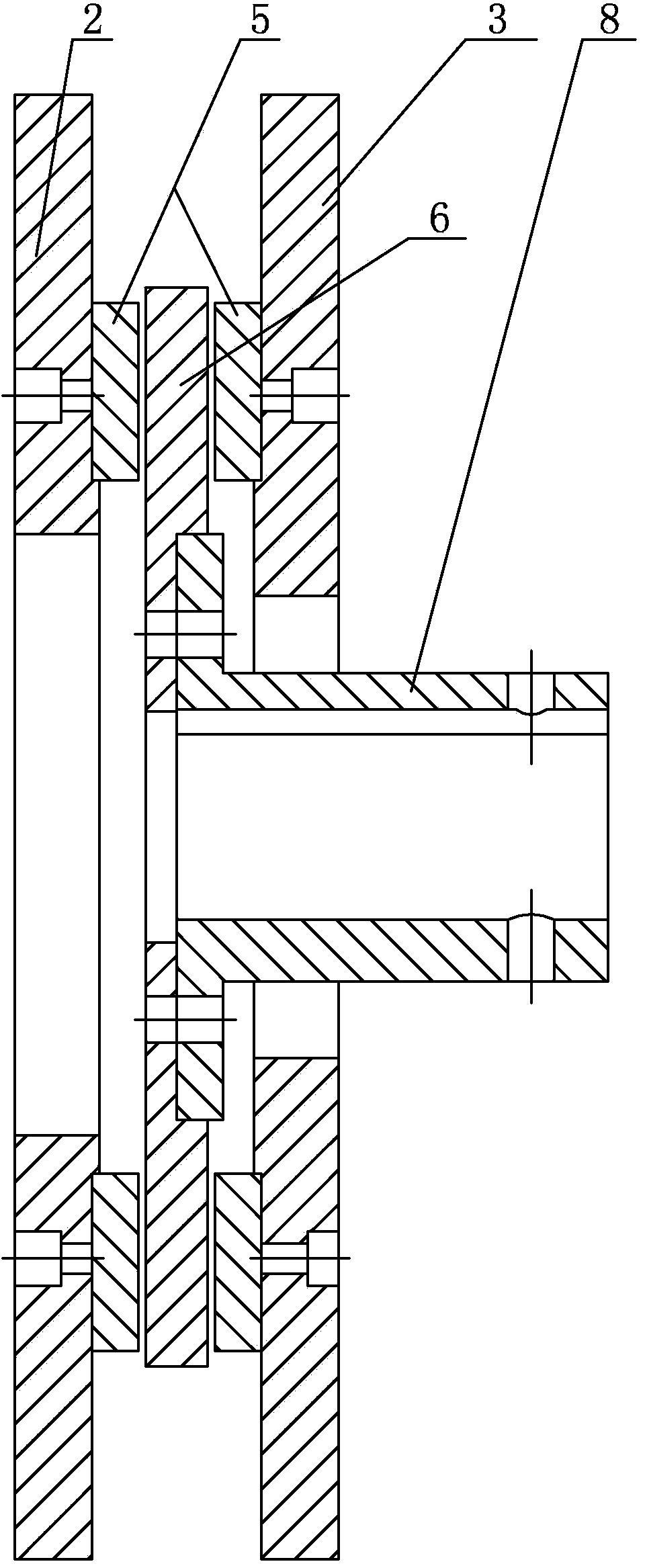

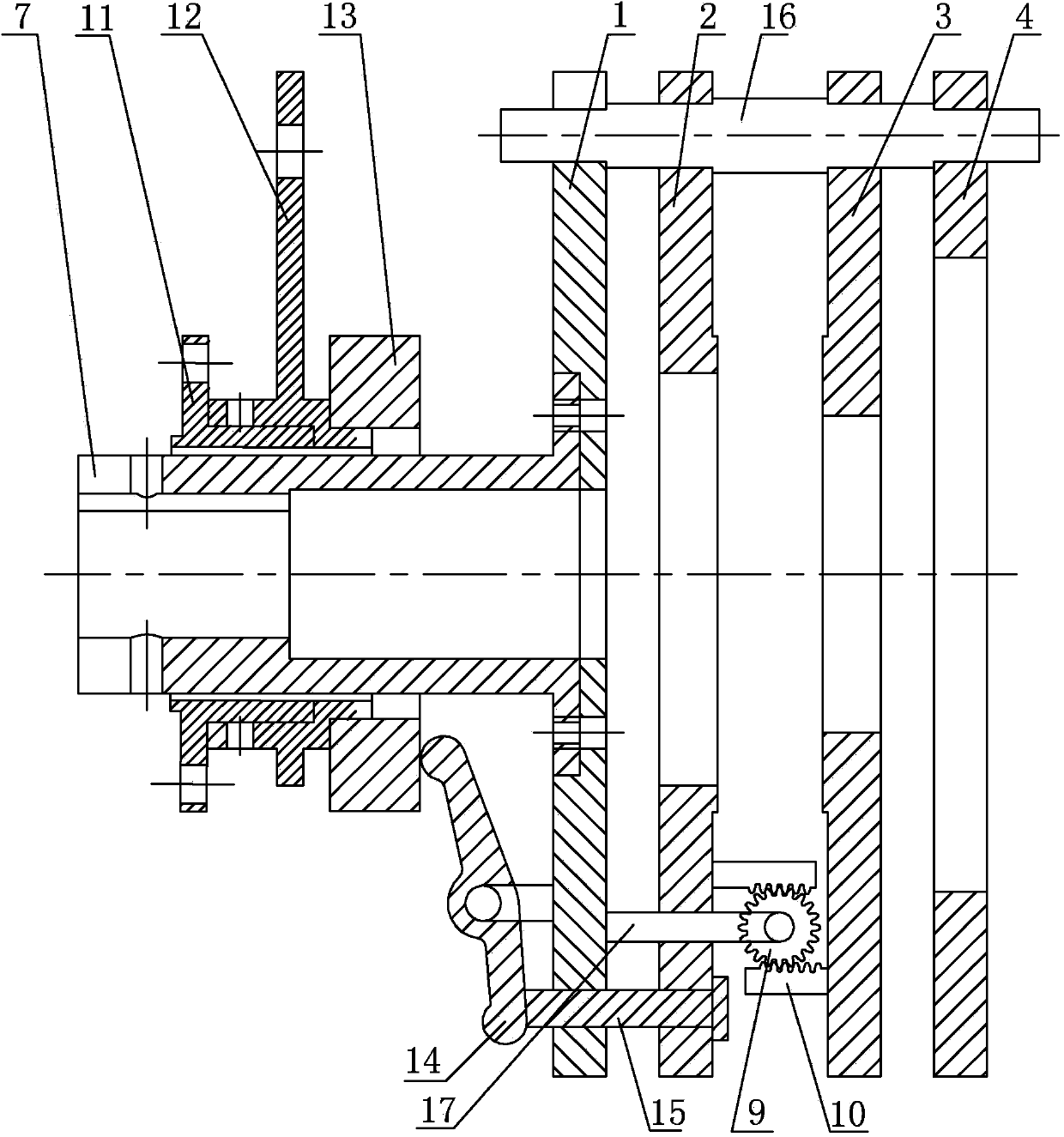

[0014] Specific implementation mode one: combine Figure 1-Figure 3 Explain that the double-sided structure speed-regulating permanent magnetic coupler of this embodiment includes a drive shaft 7, an output shaft 8, a necked flange 11, a release bearing seat 12, a release bearing 13, a first bracket 1, a second bracket 4, The first magnetically conductive active disk 2, the second magnetically conductive active disk 3, the conductive metal disk 6, at least three positioning columns 16, a plurality of permanent magnets 5 and a plurality of air gap adjustment devices;

[0015] The first bracket 1, the first magnetically conductive driving disk 2, the second magnetically conductive driving disk 3 and the second bracket 4 are arranged side by side in sequence, and the release bearing 13, the drive shaft 7 and the output shaft 8 are coaxially arranged, at least three Positioning posts 16 are evenly distributed along the circumferential direction of input shaft 7, and positioning po...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 Note that the conductive metal disc 6 in this embodiment is a copper disc. In this way, the resistivity of copper is low and the conductivity is high, which meets the requirement of permanent magnetic coupling. Others are the same as the specific implementation one.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Note that the conductive metal disc 6 in this embodiment is an aluminum disc. With such arrangement, the resistivity of aluminum is also low and the conductivity is high, which meets the requirement of permanent magnetic coupling. Others are the same as the specific implementation one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com