Horizontal ampule machine

An ampoule machine, horizontal technology, applied in the field of horizontal ampoule machines, can solve the problems of increasing production cost, increasing equipment, unstable glass composition, etc., and achieving the effect of improving the rate of genuine products, improving the conveying efficiency, and saving costs and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

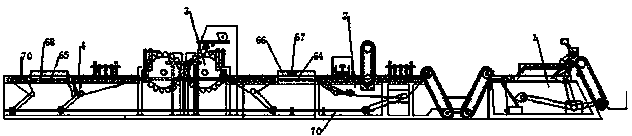

[0026] The present invention is composed of the following components: a forming mechanism 1, a printing mechanism 2, a dot scoring mechanism 3, an undercut mechanism 4, and a conveying mechanism 70.

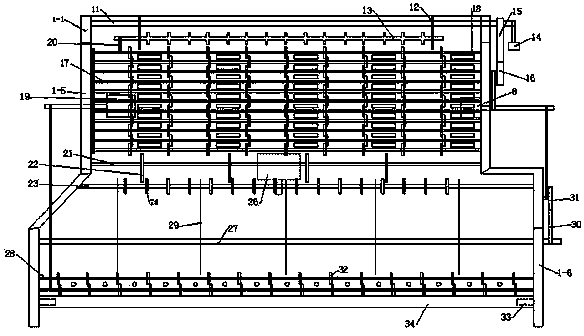

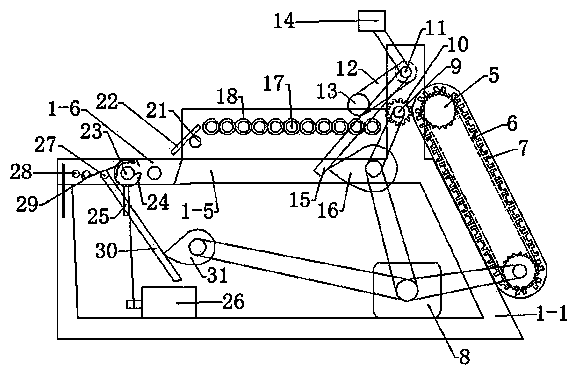

[0027] Such as figure 2 , image 3 As shown, the forming mechanism 1 is mainly composed of a frame a1-1, a pipe supply device 1-2, a stretching fuse device 1-3, and a conveying device 1-4.

[0028] The sprocket 5 of the pipe supply device 1-2 is installed on the beam of the frame a1-1, and the chain a6 is set on the two sprockets 5, and the chain a6 is driven by the sprocket 5. In order to make the glass tube can be lifted up, U-shaped guide grooves 7 are also installed at equal intervals on the chain a6, and the sprocket 5 is driven by a motor a8 installed on one side of the frame a1-1.

[0029] The rotating shaft 9 of the tensile fuse mechanism 1-3 is installed on the rear end of the frame a1-1, and the rotating shaft 9 is equipped with a pick-up wheel 10 with a U-shaped mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com