Rubber face heating method and system of pre-coated film laminating machine

A heating system and pre-coating film technology, applied in printing machines, general parts of printing machinery, printing, etc., can solve problems such as white spots, affecting the quality of the coating film, and short heating time of the pre-coating film, achieving high brightness, Increase the speed of lamination and the effect of firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

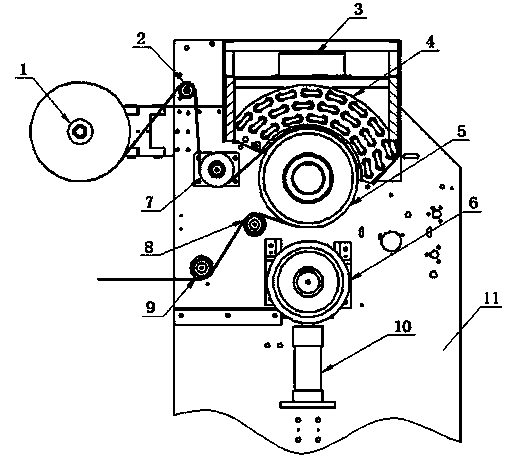

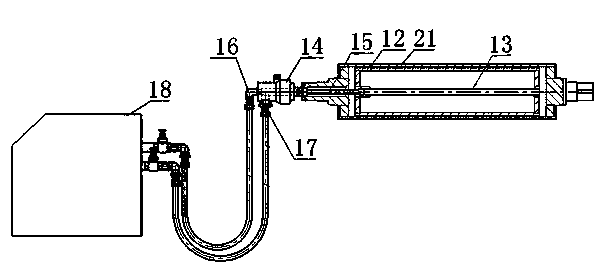

[0017] Refer to attached figure 1 , a rubber surface heating system of a pre-coating film laminating machine, comprising an axial flow fan 3, a finned tube heating system 4, a laminating steel roller 5, a laminating rubber roller 6, a bending roller 7 and a laminating machine frame 11, Laminating steel roller 5 and laminating rubber roller 6 are arranged on the frame 11 of the laminating machine, and are arranged in parallel up and down. Laminating rubber roller 6 is driven by hydraulic cylinder 10 and can move up and down. Laminating steel roller 5 is provided with a layer Finned tube heating system 4, the finned tube heating system 4 includes a plurality of interconnected finned tubes, two adjacent finned tubes are arranged in parallel, and three high-power axial flow tubes are uniformly arranged on the finned tube heating system 4 The fan 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com