Battery device and electric forklift with battery device

An electric forklift, battery technology, applied in electric vehicles, secondary battery repair/maintenance, electric traction, etc., to shorten the charging time, improve the use efficiency, and increase the charging current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

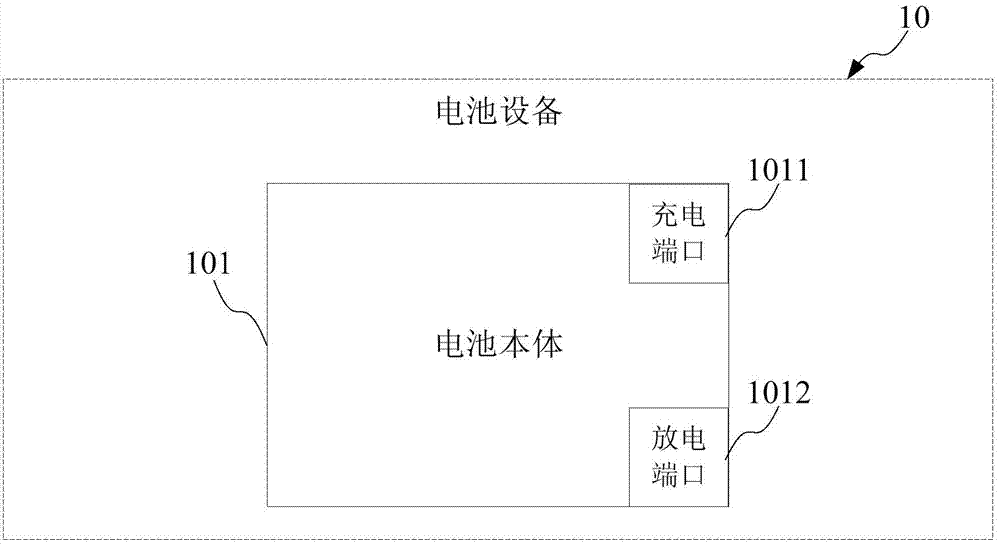

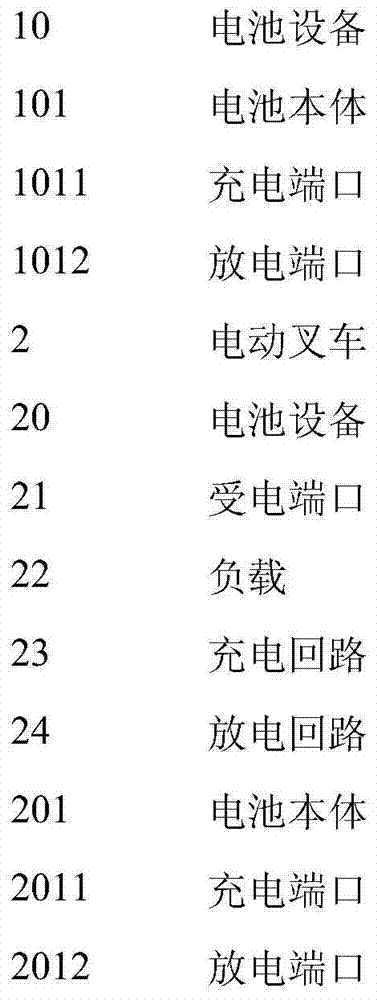

[0027] This embodiment provides a battery device 10, which is used to supply power to an electric forklift, and the electric forklift has a power receiving port for receiving a current of a first specification. Please refer to figure 1 , showing the principle structure of the battery device, the battery device 10 includes a battery body 101, and two sides of the battery body 101 are respectively provided with a charging port 1011 and a discharging port 1012.

[0028] At present, the battery equipment in the electric forklift uses a lead-acid battery. Since the charging current of the lead-acid battery is only 0.2C, when such a lead-acid battery is used, it generally takes a long time to perform slow charging and natural cooling before recharging. 1. Intermittent charging such as supplementary charging, long charging time will greatly reduce the efficiency of electric forklifts. Secondly, because the space on electric forklifts is basically occupied by large-capacity lead-acid b...

Embodiment 2

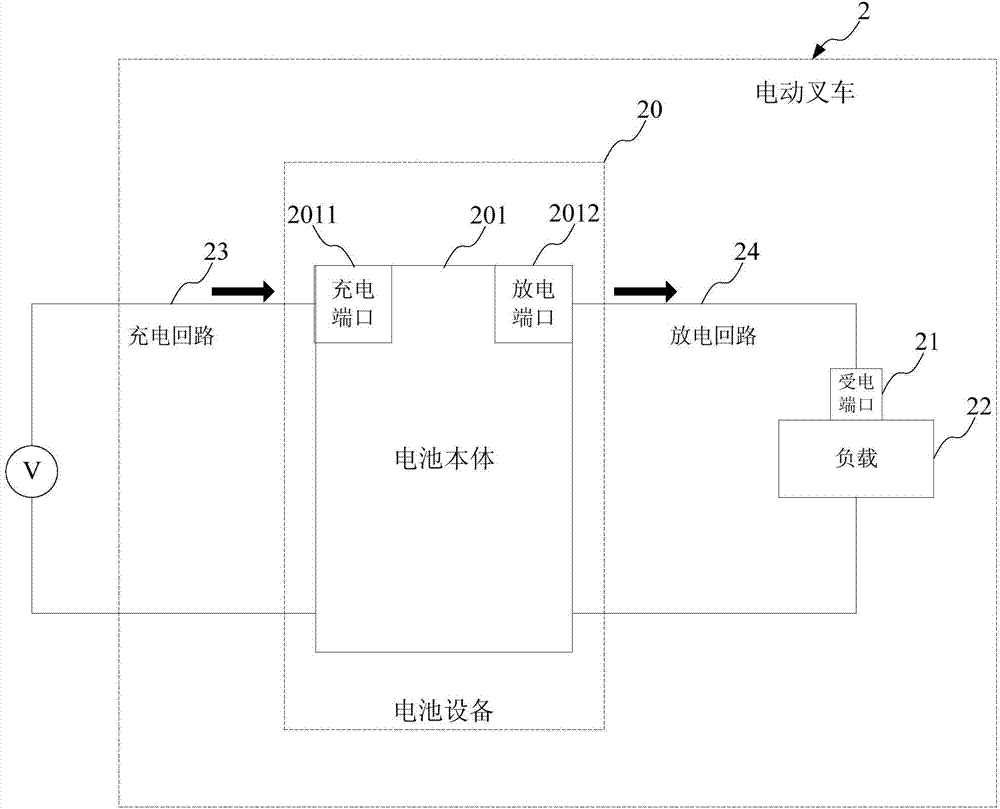

[0034] The present embodiment provides a kind of electric forklift 2, comprises the power receiving port 21 that receives the first specification electric current, cable wire, and connector, please refer to figure 2 , showing the principle structure of an electric forklift, the electric forklift 2 also includes a battery device 20 , a load 22 , a charging circuit 23 , and a discharging circuit 24 . The battery device 20 includes a battery body 201 . The battery device 20 includes a battery body 201 , and two sides of the battery body 201 are respectively provided with a charging port 2011 and a discharging port 2012 .

[0035] At present, the battery equipment in the electric forklift uses a lead-acid battery. Since the charging current of the lead-acid battery is only 0.2C, when such a lead-acid battery is used, it generally takes a long time to perform slow charging and natural cooling before recharging. 1. Intermittent charging such as supplementary charging, long charging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com