Automatically adjusted scraping device for belt conveyor

An automatic adjustment and scraper technology, applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of increased maintenance workload and transportation costs, low efficiency and inconvenience of belt conveyor material transportation, etc., to reduce the belt The effect of cleaning workload, improving material transportation efficiency, and reducing maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

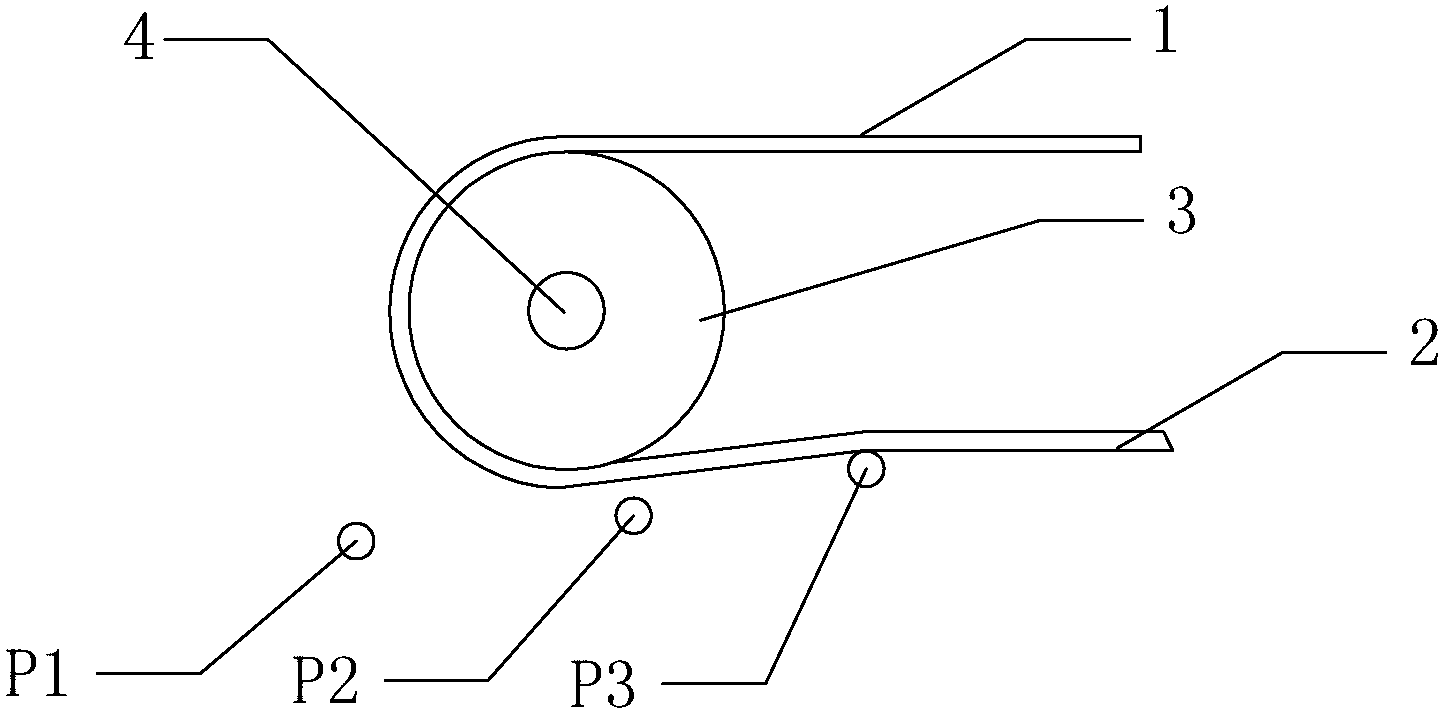

[0031] see now figure 1 , figure 1 It is a schematic diagram of the installation positions of the first scraper, the second scraper and the third scraper of the embodiment of the automatic adjustment scraper for belt conveyors of the present invention, wherein P1 is the installation position of the first scraper, and P2 is the installation position of the first scraper. 2 scraper installation position, P3 is the third scraper installation position.

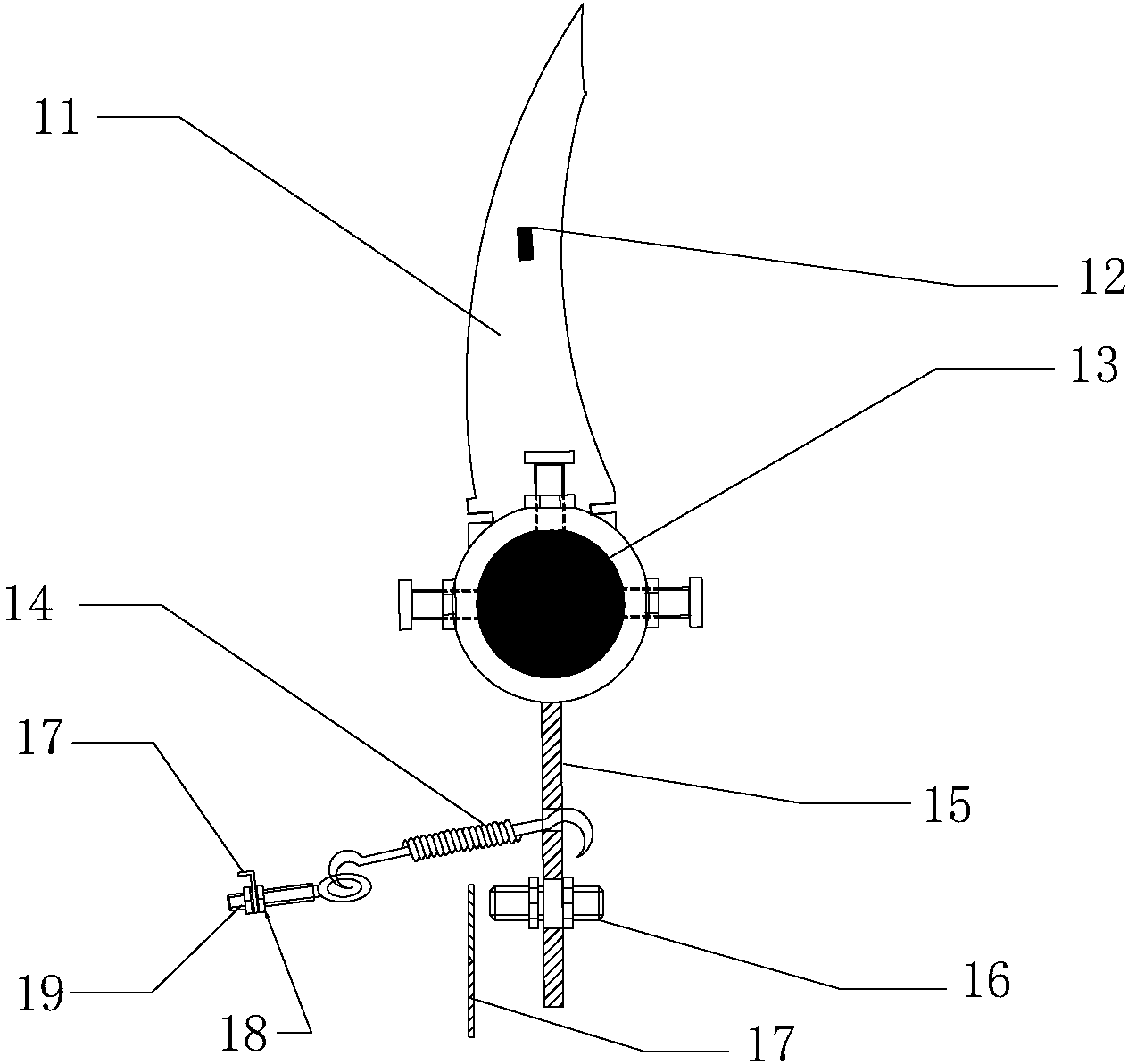

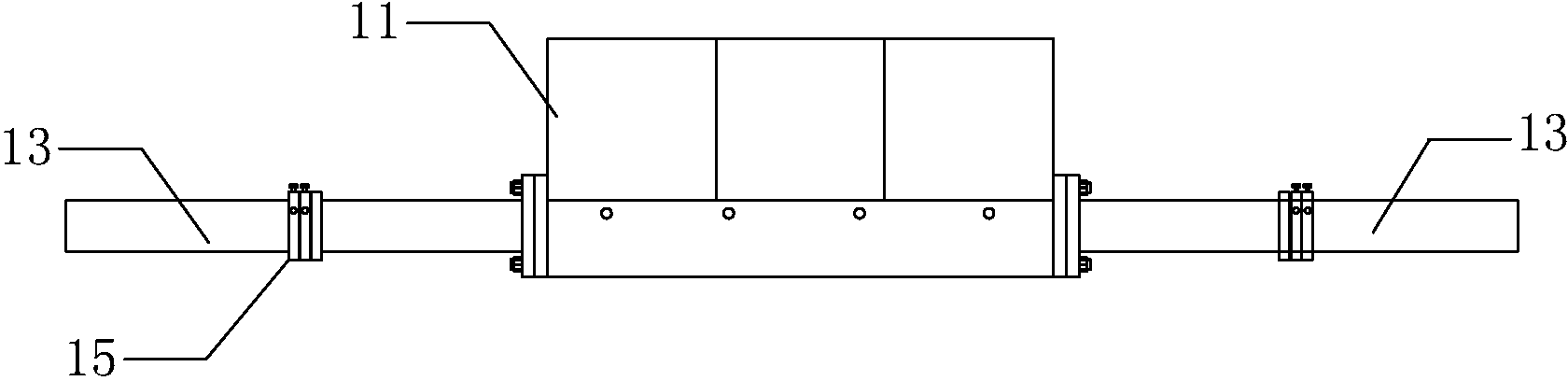

[0032] exist Figure 2 ~ Figure 4 middle, figure 2 It is a schematic structural view of the first scraper in the embodiment of the present invention, image 3 It is a schematic diagram of the connection between the scraper and the support pipe of the first scraper of the embodiment of the present invention, Figure 4 for figure 2 Schematic diagram of the top structure where the scraper plate of the first scraper contacts the upper belt. As shown in the figure, the first scraper is equipped with a spring tension mechanism t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com