Capper for containers

A technology for sealing machines and containers, applied in the directions of sealing machines, tightly closing containers with lids, bottle/container caps, etc. The effect of removal, efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

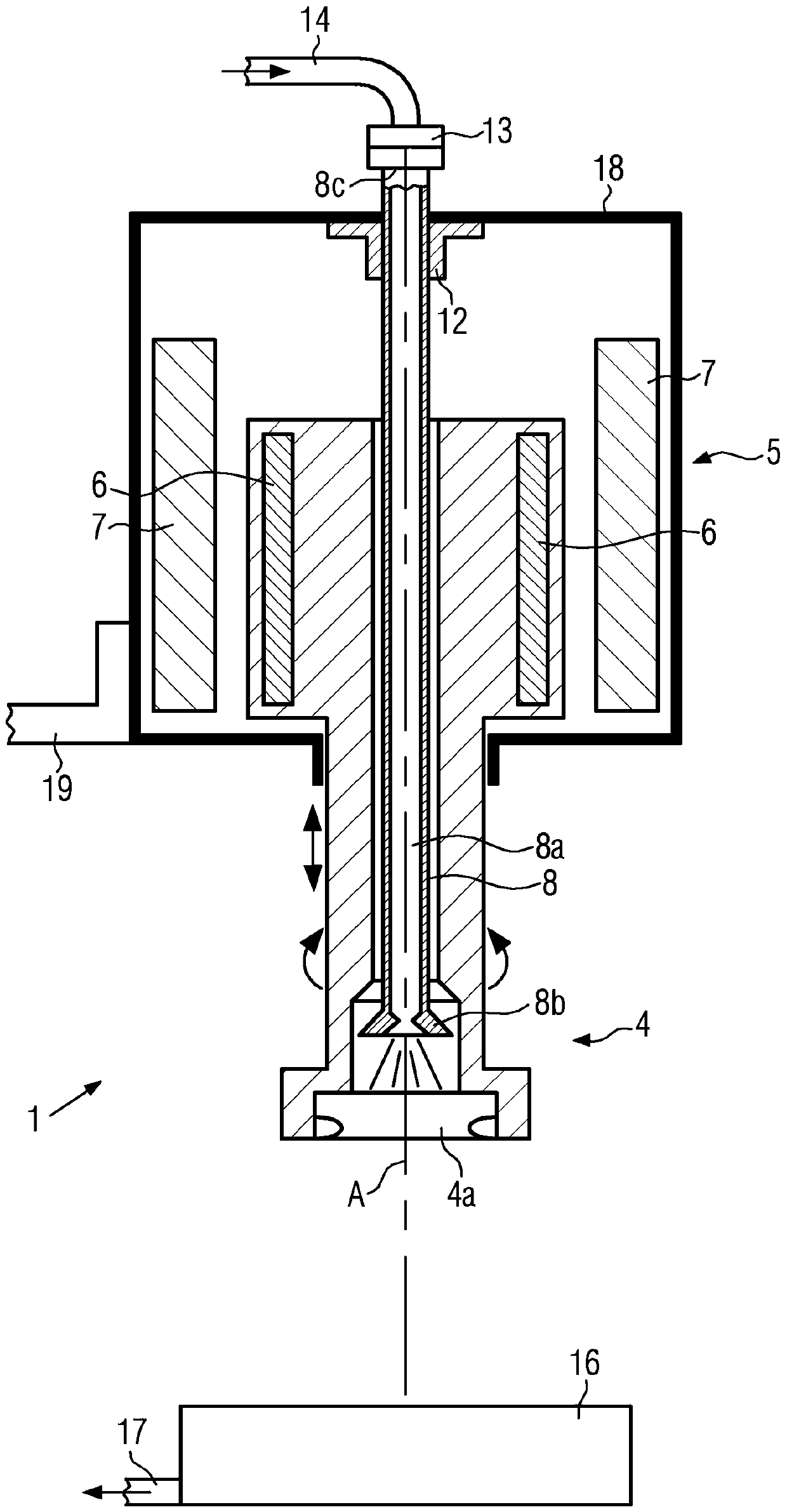

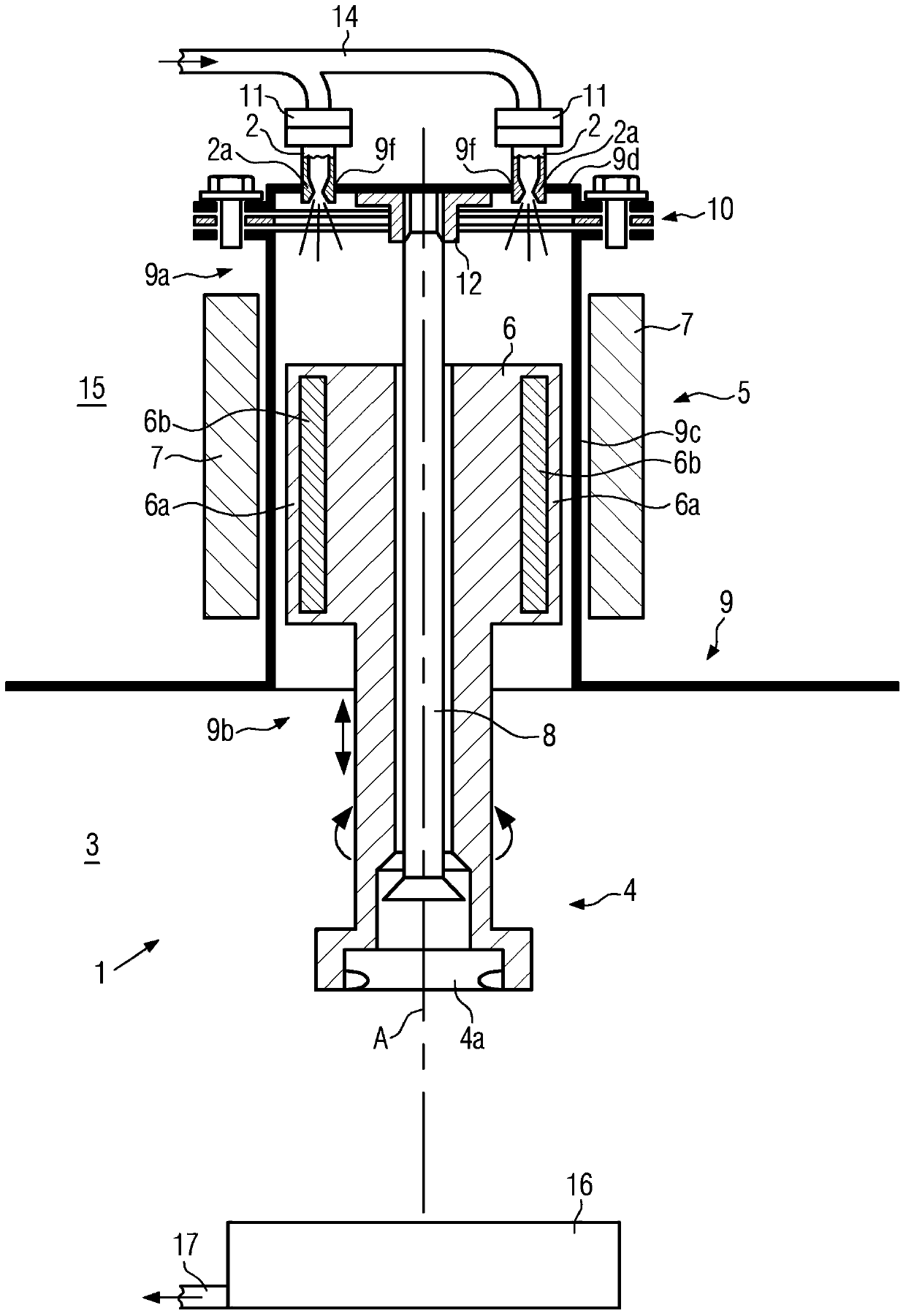

[0040] figure 1 A cross-sectional side view of the first embodiment of the sealing machine according to the present invention during cleaning is shown. The motor 5 can be seen, and its rotor 6 drives the closing head 4 in the following manner, so that the closing head can not only perform vertical lifting movements, but also rotate around the axis A. In addition, an ejector rod 8 is arranged in the closure head 4 so as to eject the container closure that is suspended in the closure head 4 or not screwed onto the container.

[0041] The stator 7 of the motor 5 generates a magnetic field, and the magnetic field acts on the magnet of the rotor 6. The stator 7 here includes a plurality of magnetic coils along the axis A and in the peripheral direction, respectively. As a result, it is possible to generate a magnetic field that can not only rotate the rotor 6 around the axis A, but also adjust the height along the axis A (according to the arrow). In the sealing machine 1, the closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com