Sewage flocculation and blow-down system

A sewage system and sewage technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of backward sewage discharge methods, poor supernatant water quality, and inability to fully self-control and adjust the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

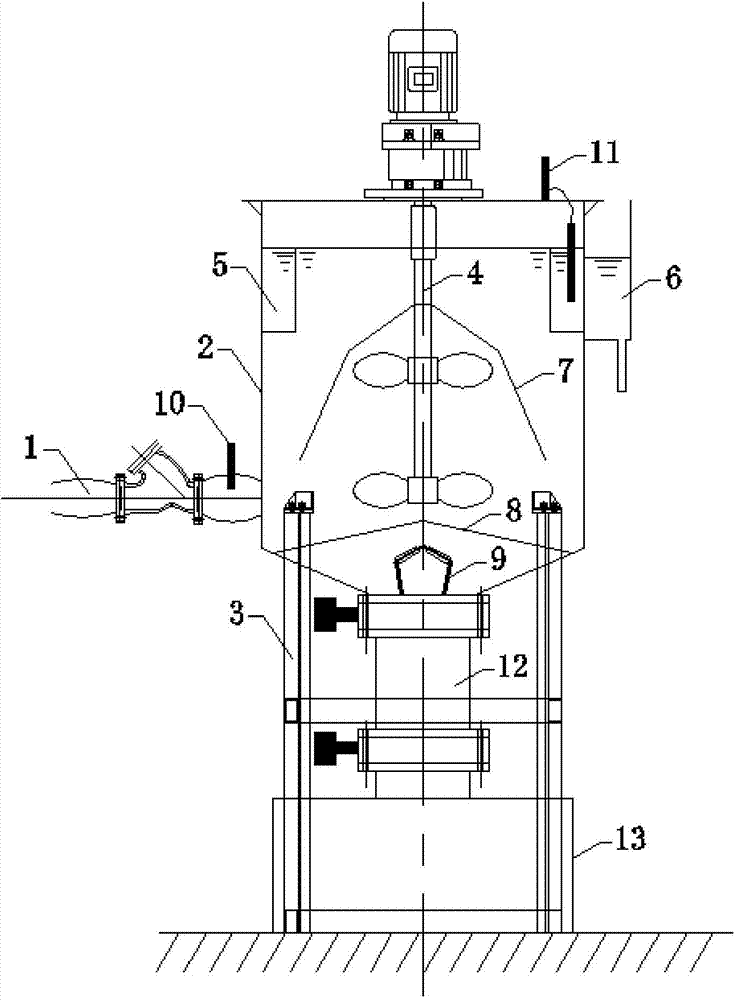

[0018] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

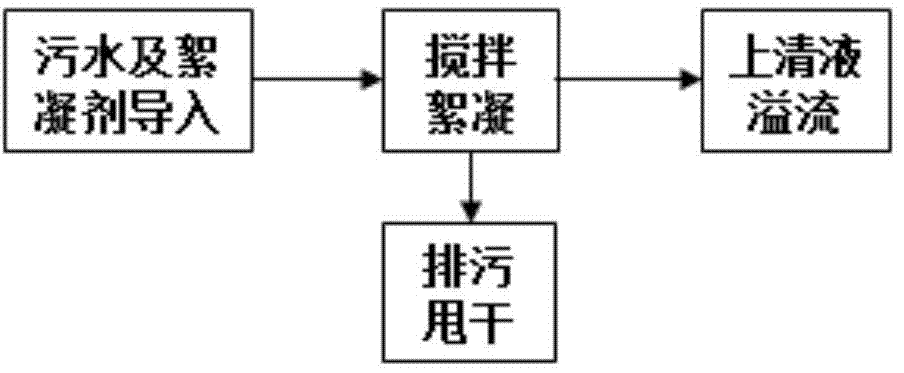

[0019] Such as figure 1 As shown, in the sewage flocculation and sewage system of the prior art, sewage and flocculant are input into the tank according to a certain constant ratio, and the mixer mixes and flocculates it at a fixed speed, and then it will be determined according to experience During downtime, the supernatant liquid is pumped out and stored externally, while the flocculated dirt at the bottom of the tank is drained and closed by manual opening.

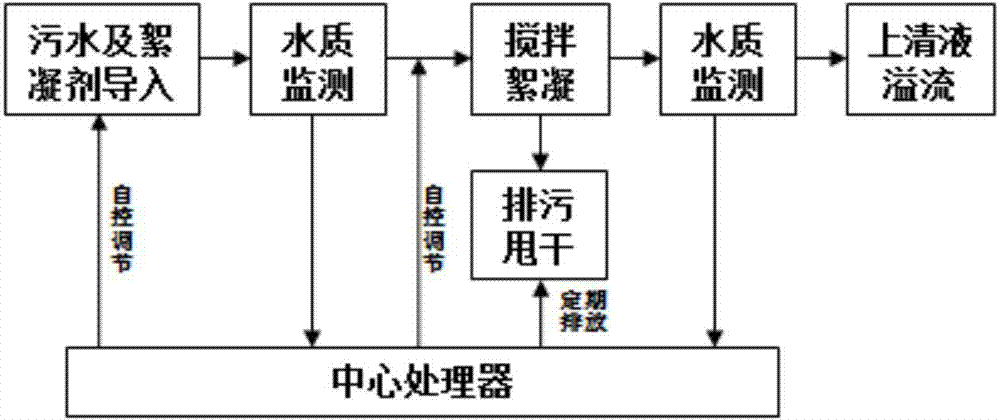

[0020] Such as figure 2 Shown is a specific embodiment of the sewage flocculation sewage system of the present invention. It differs from existing technologies such as figure 1 The difference between the sewage flocculation and sewage discharge system shown is that the present invention uses two-stage water quality monitoring, that is, the central processor monitors the water quality of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com