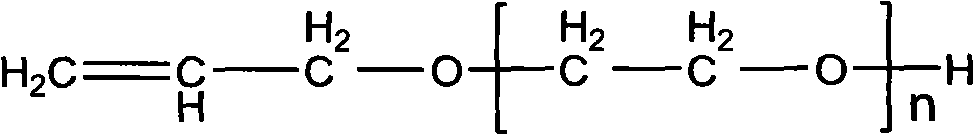

Preparation method of novel concrete slump retaining agent based on allyl polyoxyethylene ether

A technology of allyl polyoxyethylene ether and slump-retaining agent, applied in the polymer field, can solve problems such as insufficient slump-retaining performance of concrete, and achieve the effects of simple production process, wide source of raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

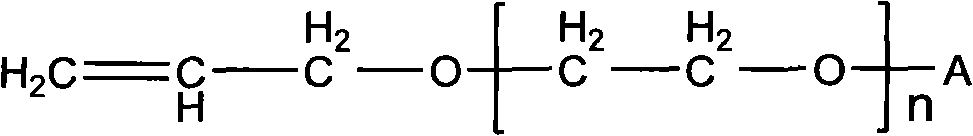

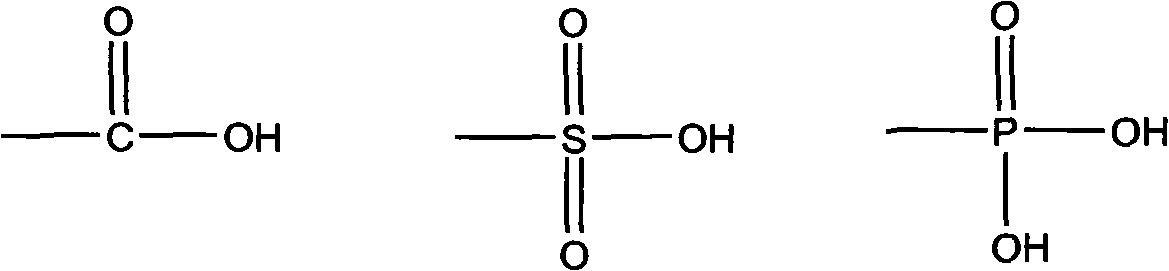

[0026] In a 1L glass flask, add 220g of deionized water, 240g of allyl polyoxyethylene ether APEG-2400 (molecular weight 2400), 120g of allyl polyoxyethylene ether sulfonate ammonium ASPEG-1200 (molecular weight of 1200), and mix well. Turn on the stirring and raise the temperature to 85°C. Start to drop the monomer solution (composition: 45g acrylic acid + 180g deionized water) and initiator solution (composition: 4g sodium persulfate + 220g deionized water) respectively, and drop them evenly within 3 hours. After holding at 85°C for 1 hour, the temperature of the solution was lowered to 40-50°C. Add 32% NaOH, adjust the system to pH 5.8-6.2, and prepare a new type of slump-retaining agent SP-A with a weight-average molecular weight of 35,000 and a solid content of 40%.

Embodiment 2

[0028] In a 1L glass flask, add 220g deionized water, 240g allyl polyoxyethylene ether APEG-2400 (molecular weight 2400), 120g allyl polyoxyethylene ether monophosphonic acid disodium APPPEG-1200 (molecular weight 1200), mix uniform. Turn on the stirring and raise the temperature to 85°C. Start to add monomer solution (composition: 45g acrylic acid + 180g deionized water) and initiator solution (composition: 4g sodium persulfate + 220g deionized water) dropwise respectively, and drop them uniformly within 3 hours. After holding at 85°C for 1 hour, the temperature of the solution was lowered to 40-50°C. Add 32% NaOH, adjust the system to pH 5.8-6.2, and prepare a new type of slump-retaining agent SP-B with a weight-average molecular weight of 38,000 and a solid content of 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com