Soft soil roadbed drainage prepressing rear blocking structure and construction method

A soft soil roadbed and horizontal drainage technology, applied in infrastructure engineering, roads, roads, etc., can solve the problems of long construction period, low strength, and high engineering cost, and achieve the effect of enhancing integrity and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In this embodiment, the design and construction technical requirements of the embankment and pavement structure, the construction technical requirements of the horizontal drainage cushion, the vertical drainage body horizontal grouting pipe, and the vertical grouting pipe will not be repeated in this embodiment, and the emphasis will be on The invention relates to embodiments of structures.

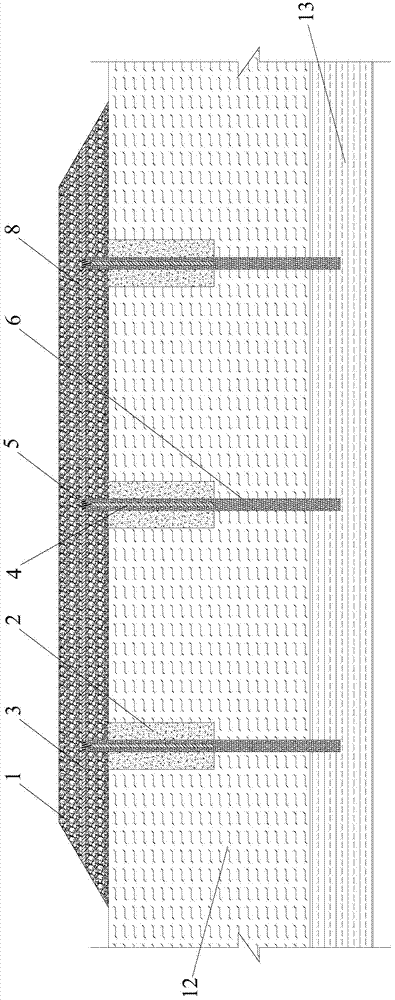

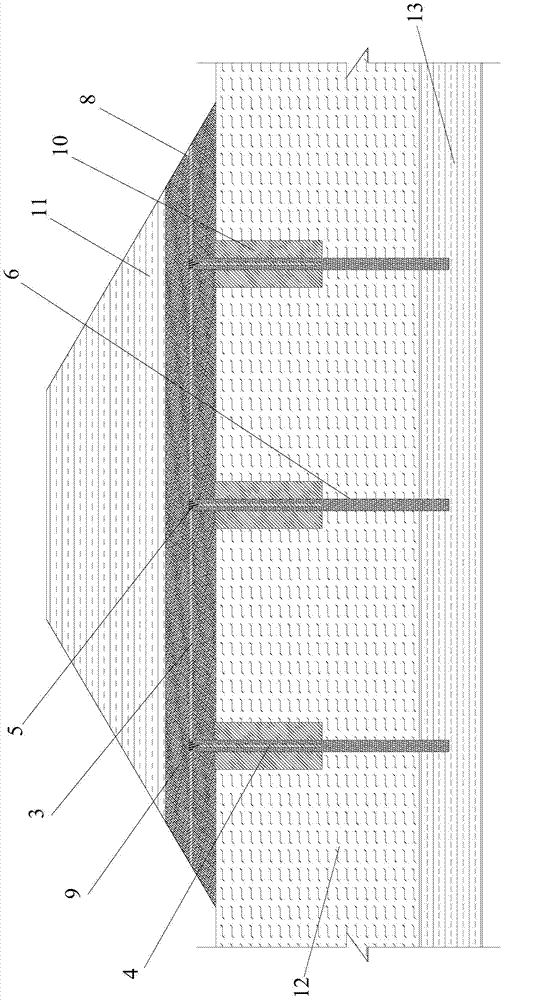

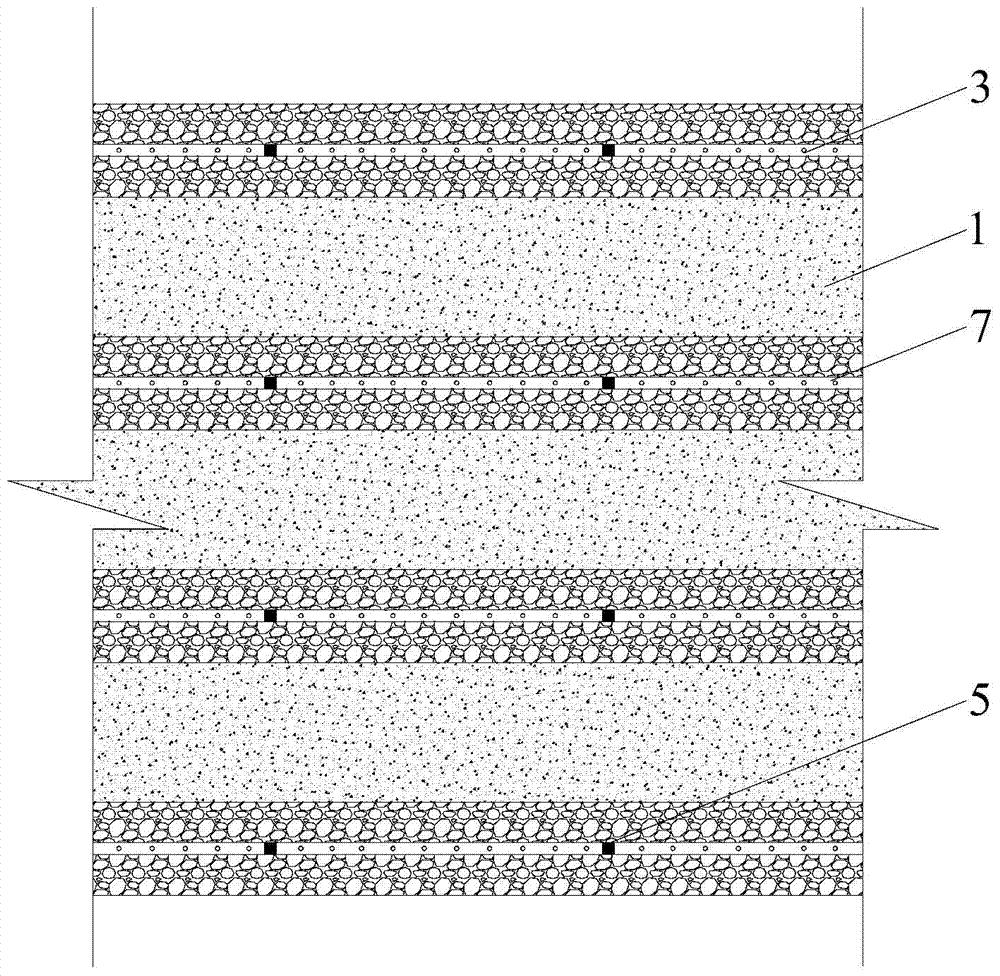

[0033] figure 1 It is a cross-sectional view of the soft soil subgrade drainage preloading period structure of the present invention, figure 2 It is a cross-sectional view of the structure in the plugging period after drainage of the soft soil subgrade of the present invention, image 3 It is a horizontal sectional view of the plugging structure after drainage and preloading of the soft soil roadbed of the present invention. refer to figure 1 , figure 2 , image 3 As shown, the road to be reinforced is a two-way six-lane first-class road, and the cross section after the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com