A marine dual-fuel/gas engine gas multi-point multi-stage injection system

A gas engine and injection system technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problem of not being able to simultaneously meet the requirements of engine gas injection flow and accuracy, low economic emission, engine economy and emission change Improve the accuracy of gas injection control, improve power performance, and improve the uniformity of fuel distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

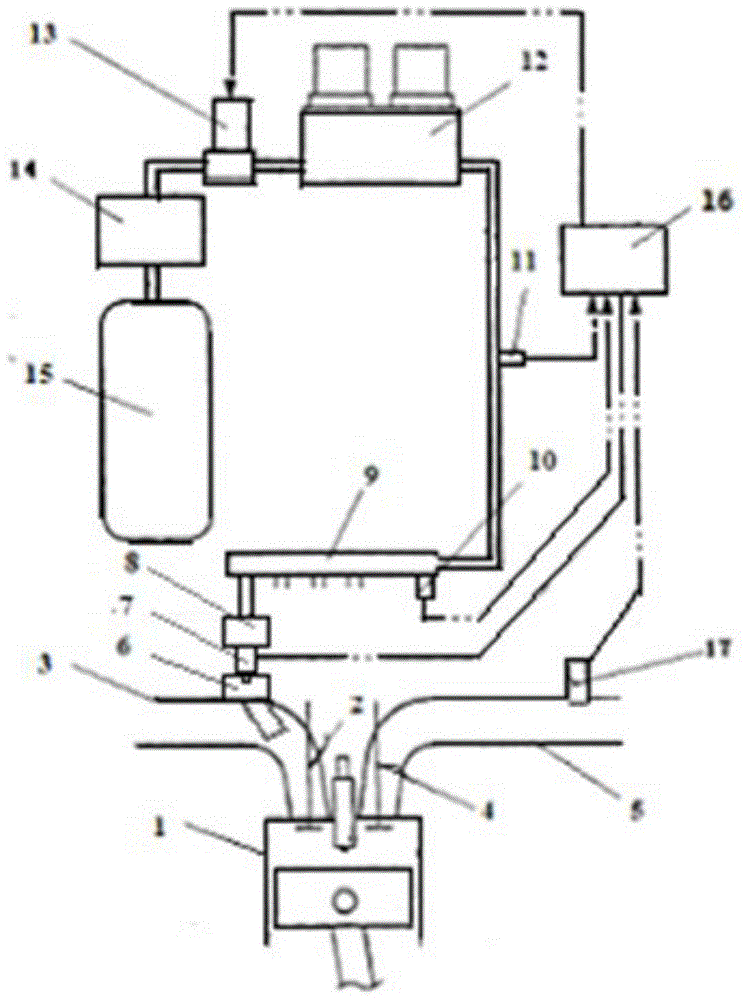

[0022] Attached below Figure 1-5b The present invention is further described.

[0023] A marine dual-fuel / gas engine gas multi-point multi-stage injection system mainly includes a gas fuel storage and supply system, a gas multi-point multi-stage injection assembly and a control system 16.

[0024] The gas fuel storage and supply system is mainly composed of gas fuel storage device 15, fuel supply pipeline, filter 14, pressure regulating device 12 and switch solenoid valve 13;

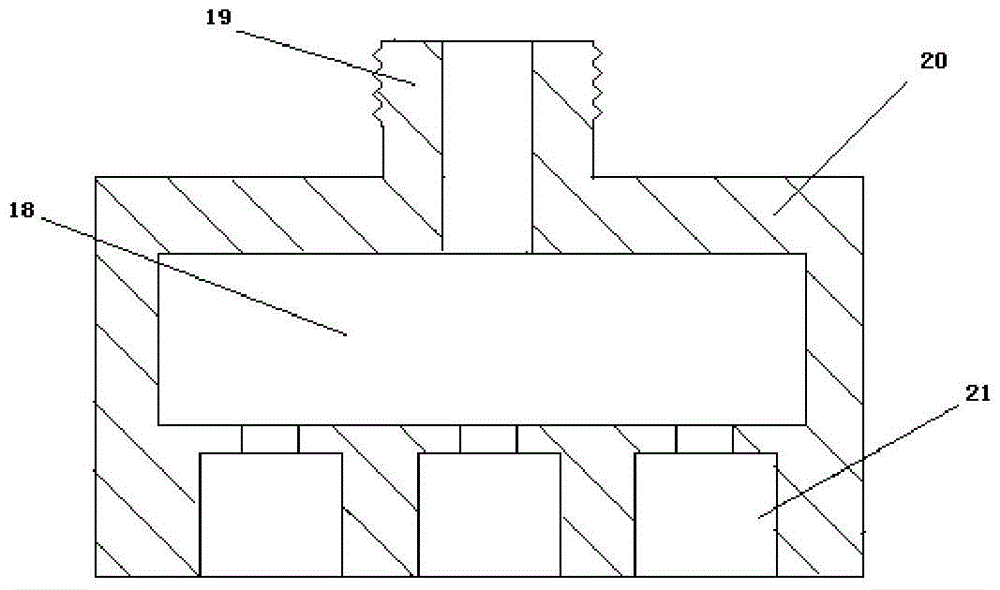

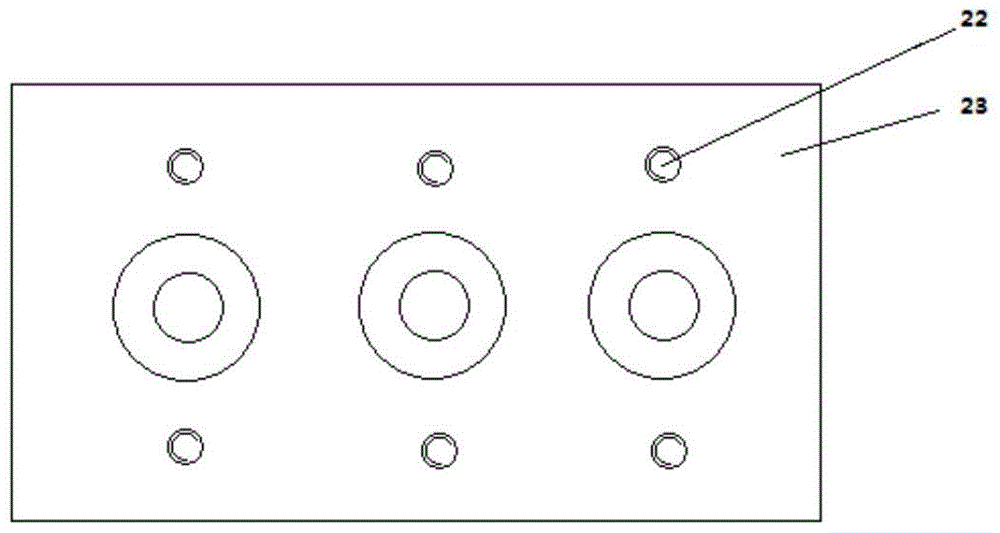

[0025] The gas multi-point multi-stage injection assembly is composed of a gas rail pipe 9, a gas pressure stabilizing chamber 8, a gas collector 6 and an air injection valve group 7. The gas rail pipe 9 is fixed on the engine and connected with the gas stabilizing chamber 8. The gas injection valve group 7 is assembled in the gas plenum chamber 8 and installed on the gas collector 6 which is installed on the intake manifold 3 .

[0026] The control system 16 is connected with each gas injection valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com