Industrial field data collecting and analyzing system based on Modbus

A technology for data collection and analysis and industrial sites, applied in digital transmission systems, transmission systems, data exchange networks, etc., can solve the problem of inability to provide data object description, storage, analysis, inability to meet industrial production information management, and inability to support large data Object etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

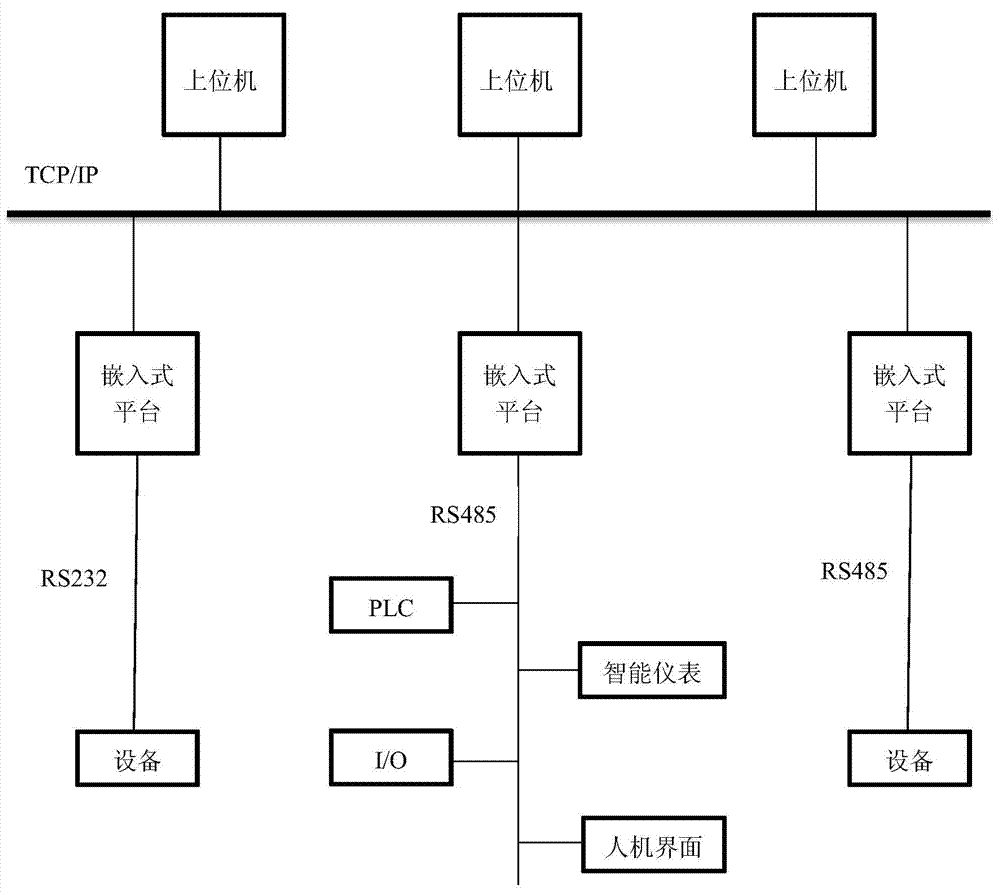

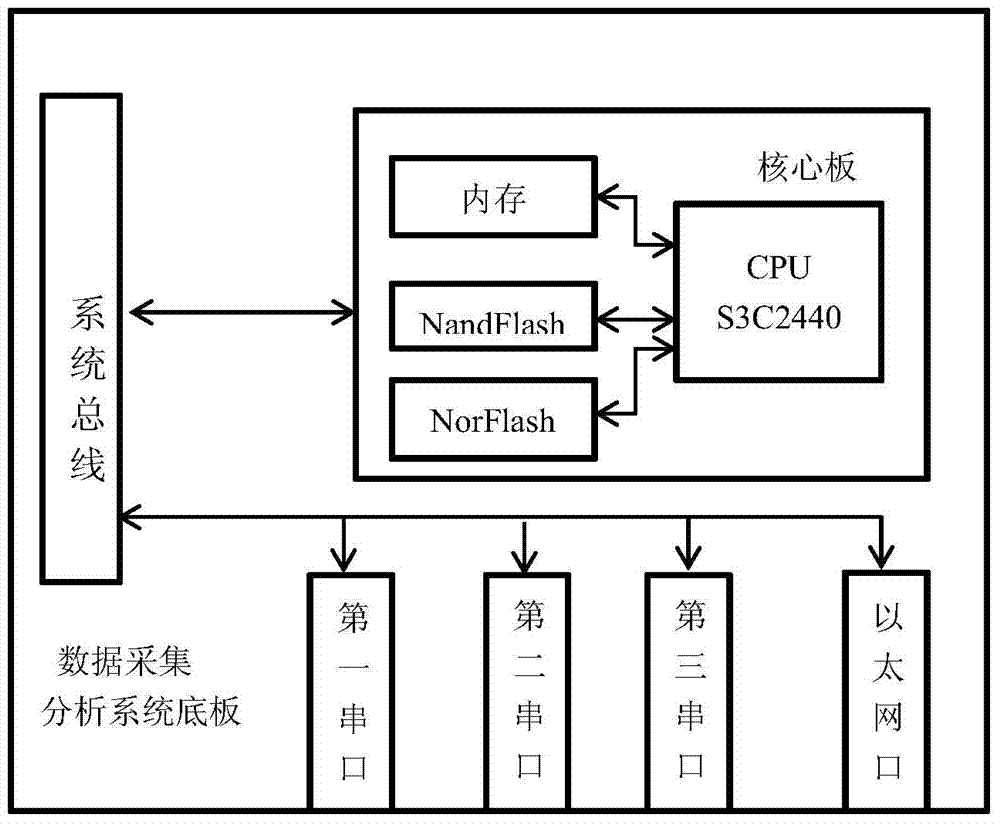

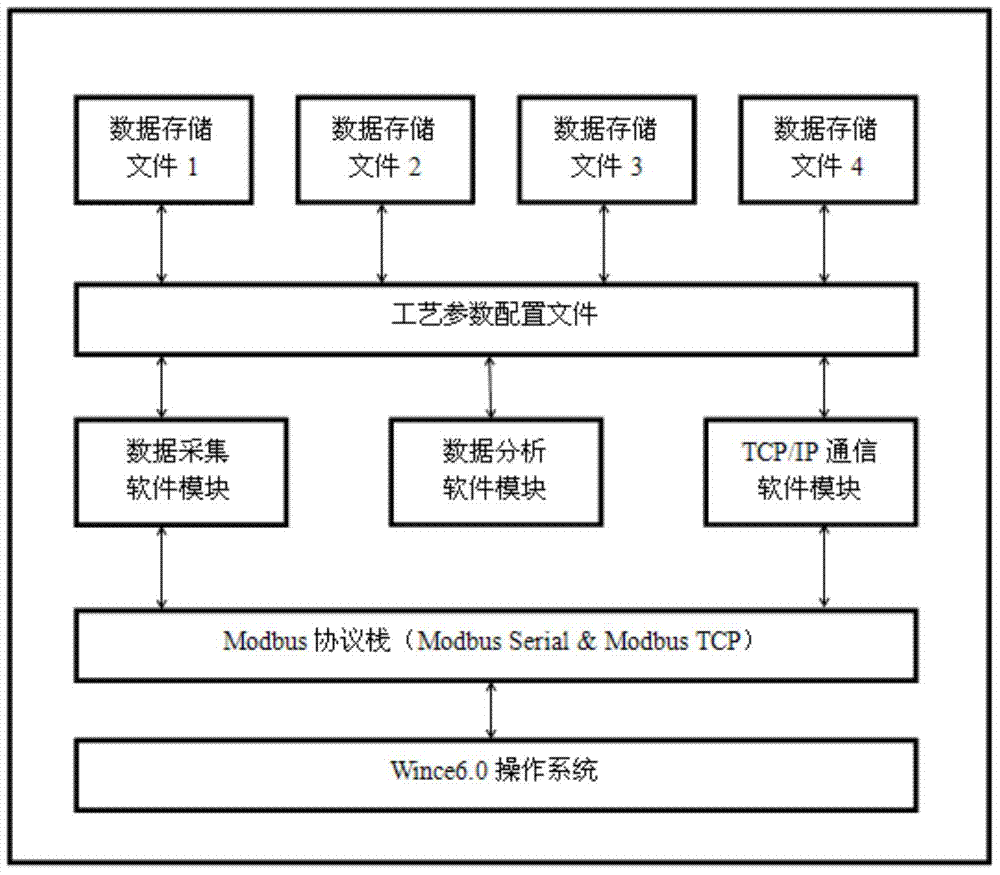

[0031] A kind of industrial field data acquisition and analysis system based on Modbus of the present embodiment, such as Figure 1-7 Shown, comprise upper computer, embedded platform, Modbus equipment and network; Described embedded platform is connected with Modbus equipment or network by RS232 or RS485 bus line, and described embedded platform is by data collection period to Modbus equipment or in the network Process parameters are queried and read, stored in the embedded platform, and analyzed and managed through the embedded platform; in addition, the embedded platform is also connected to the local area network or the external Internet through the Ethernet interface, and by responding to the host computer request, Realize remote information management and monitoring of industrial automation production.

[0032] The upper computer is provided with a Wince embedded operating system, and the Wince embedded operating system is used to manage the hardware resources and framew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com