Multilayer wiring substrate

A multi-layer wiring substrate and insulating layer technology, applied in the direction of multi-layer circuit manufacturing, electrical components, printed circuit components, etc., can solve the problem of inability to obtain adhesion, and achieve the effect of preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

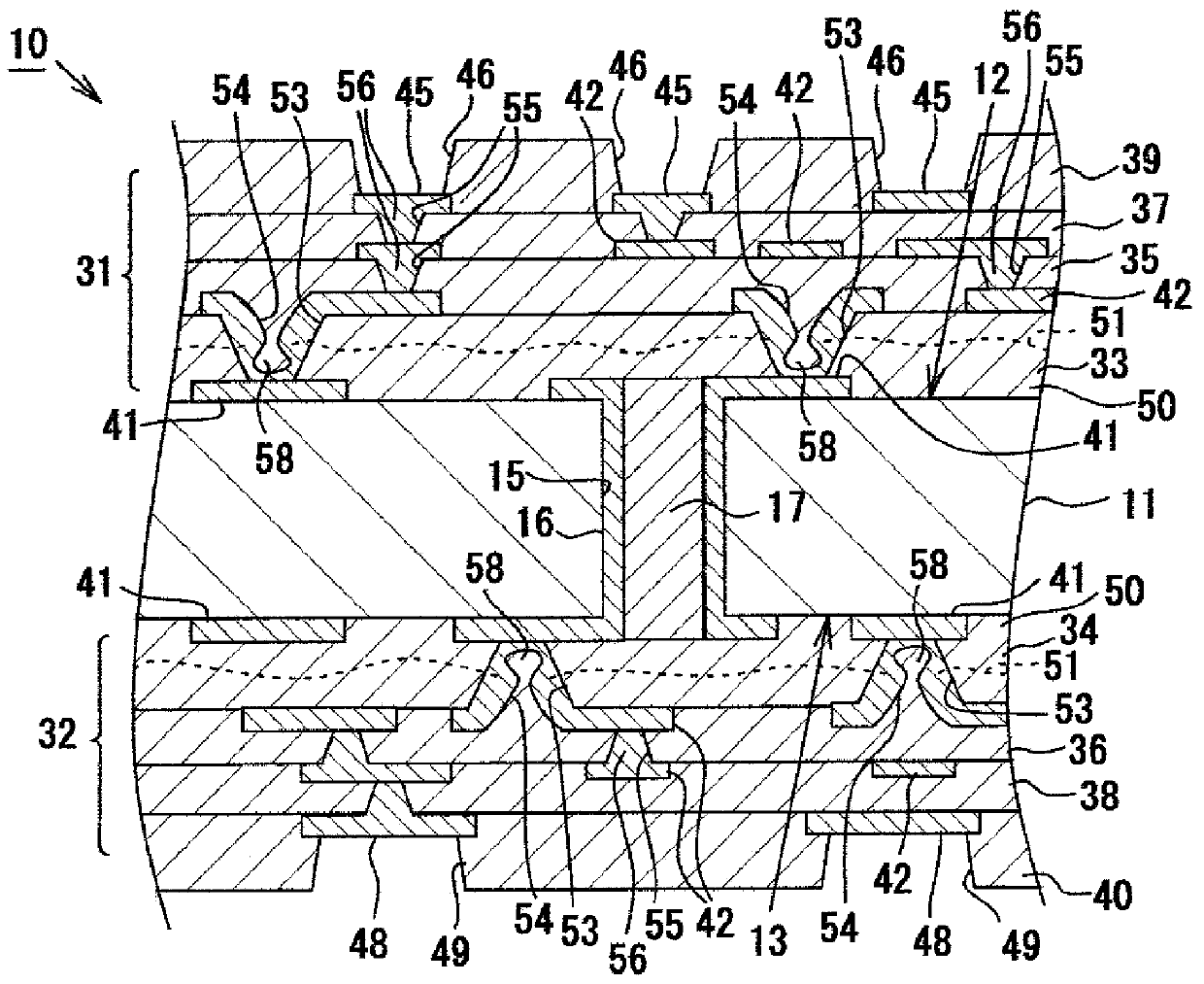

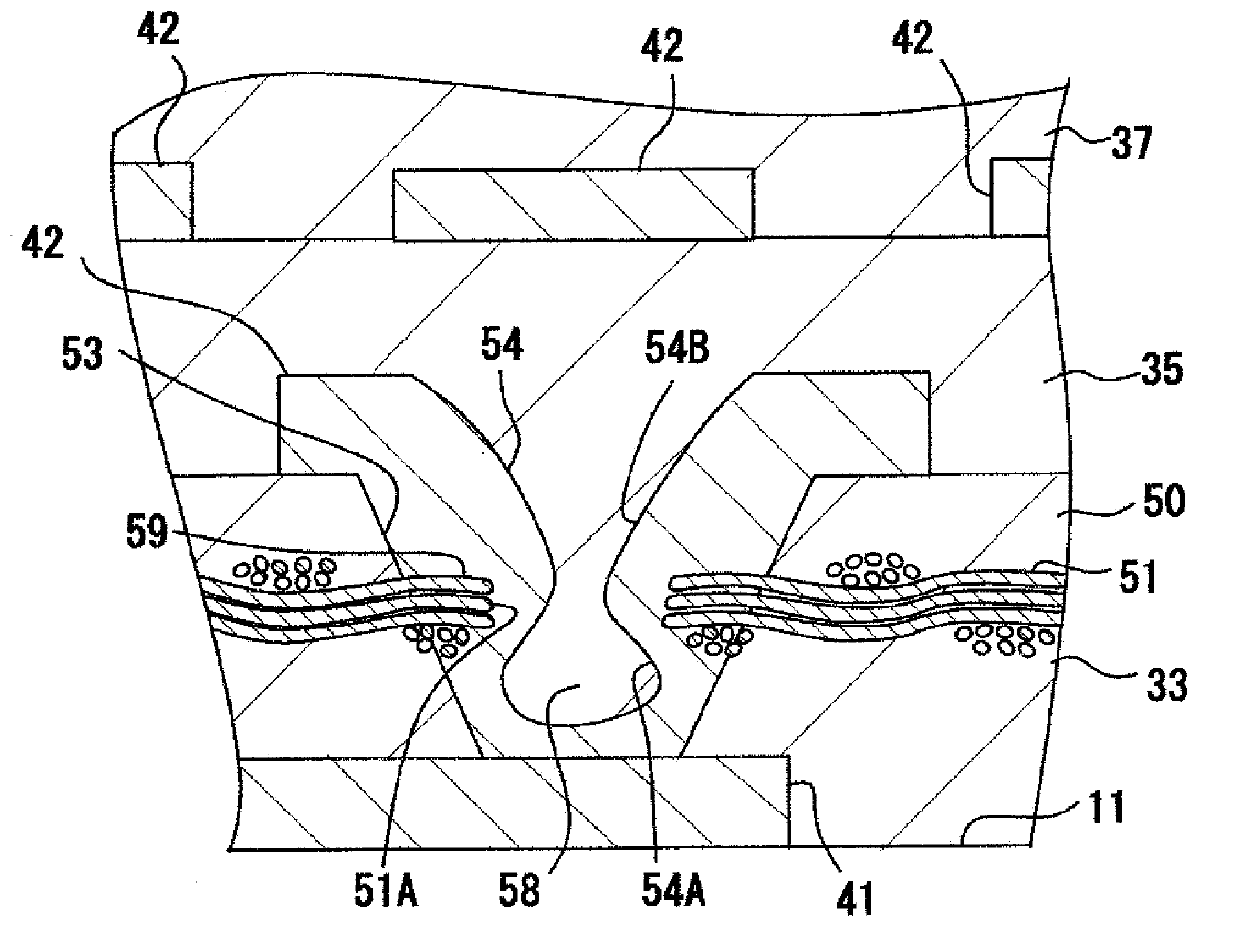

[0031] Hereinafter, an embodiment in which the present invention is embodied in a multilayer wiring board will be described in detail with reference to the drawings.

[0032] Such as figure 1 As shown, the multilayer wiring substrate 10 of the present embodiment includes a core substrate 11, a core main surface 12 formed on the core substrate 11 ( figure 1 The first buildup layer 31 on the upper surface) and the core back surface 13 formed on the core substrate 11 ( figure 1 The middle is the second build-up layer 32 on the lower surface).

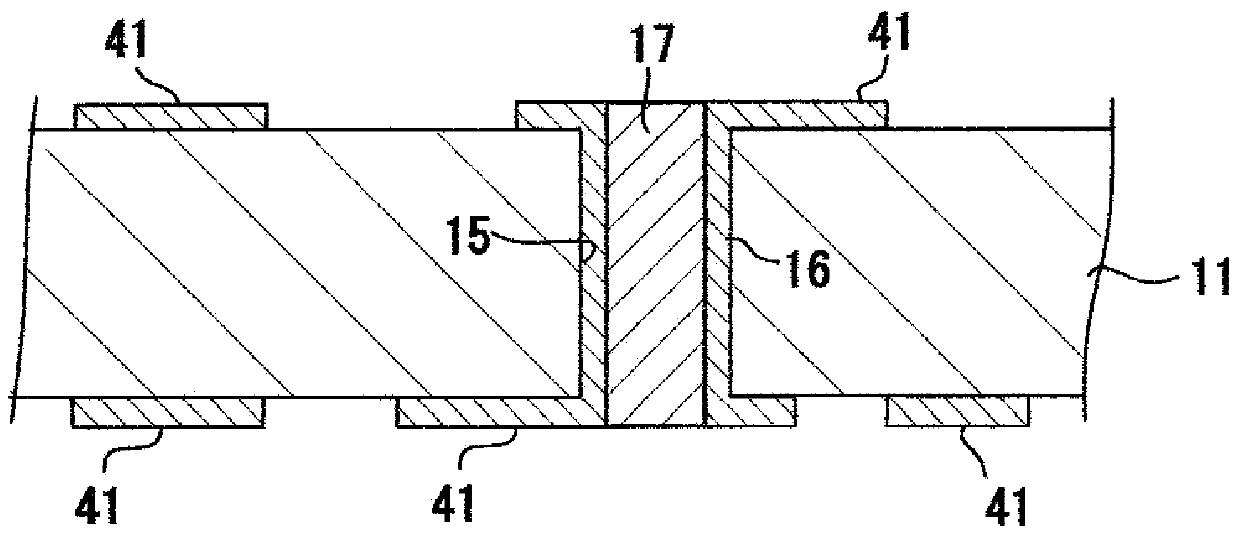

[0033] The core substrate 11 is constituted by, for example, a resin insulating material (glass epoxy resin material) obtained by impregnating glass fiber cloth as a reinforcing material with epoxy resin. Conduction holes 15 (through holes) penetrating through the core substrate 11 in the thickness direction are formed at a plurality of locations on the core substrate 11 , and via conductors 16 are formed in the conduction holes 15 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com