Vanadium phosphorus oxide (VPO) catalyst and application thereof in preparation of acraldehyde from glycerol in dewatering manner

A catalyst and acrolein technology, applied in the direction of physical/chemical process catalysts, carbon-based compound preparation, organic compound preparation, etc., to achieve high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

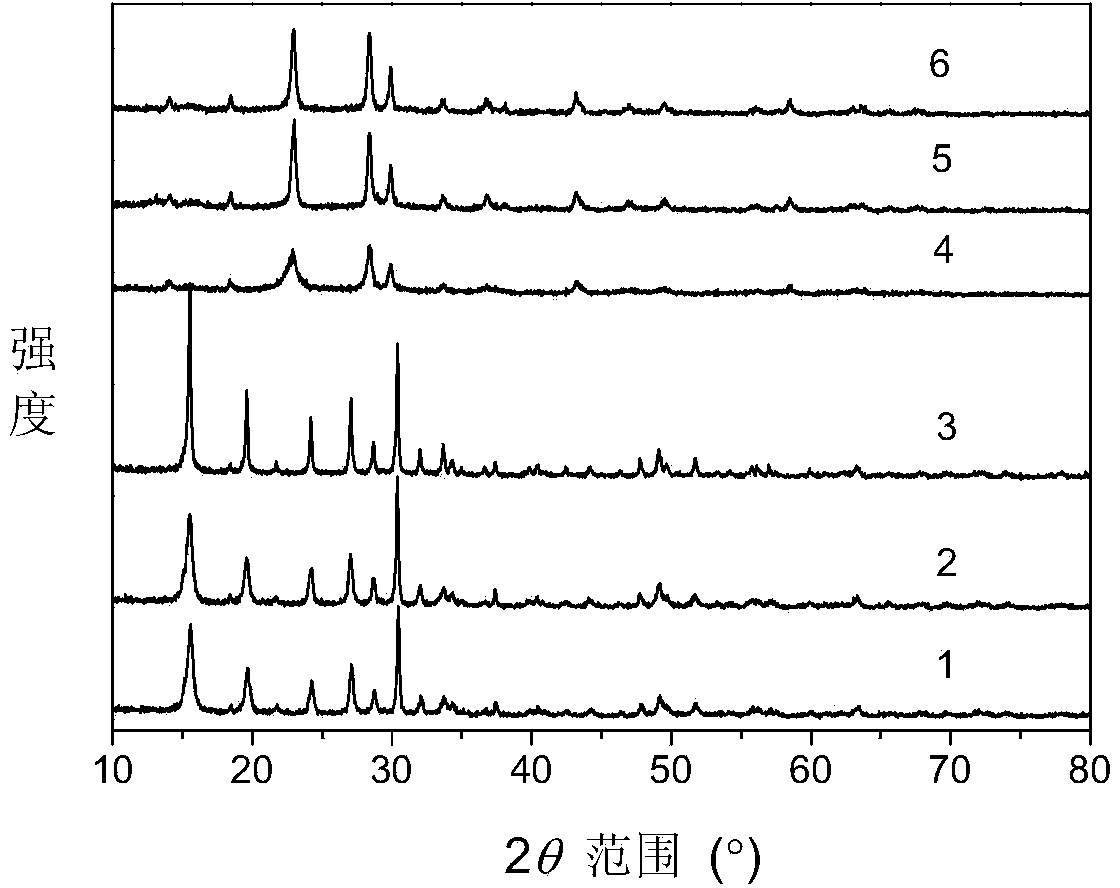

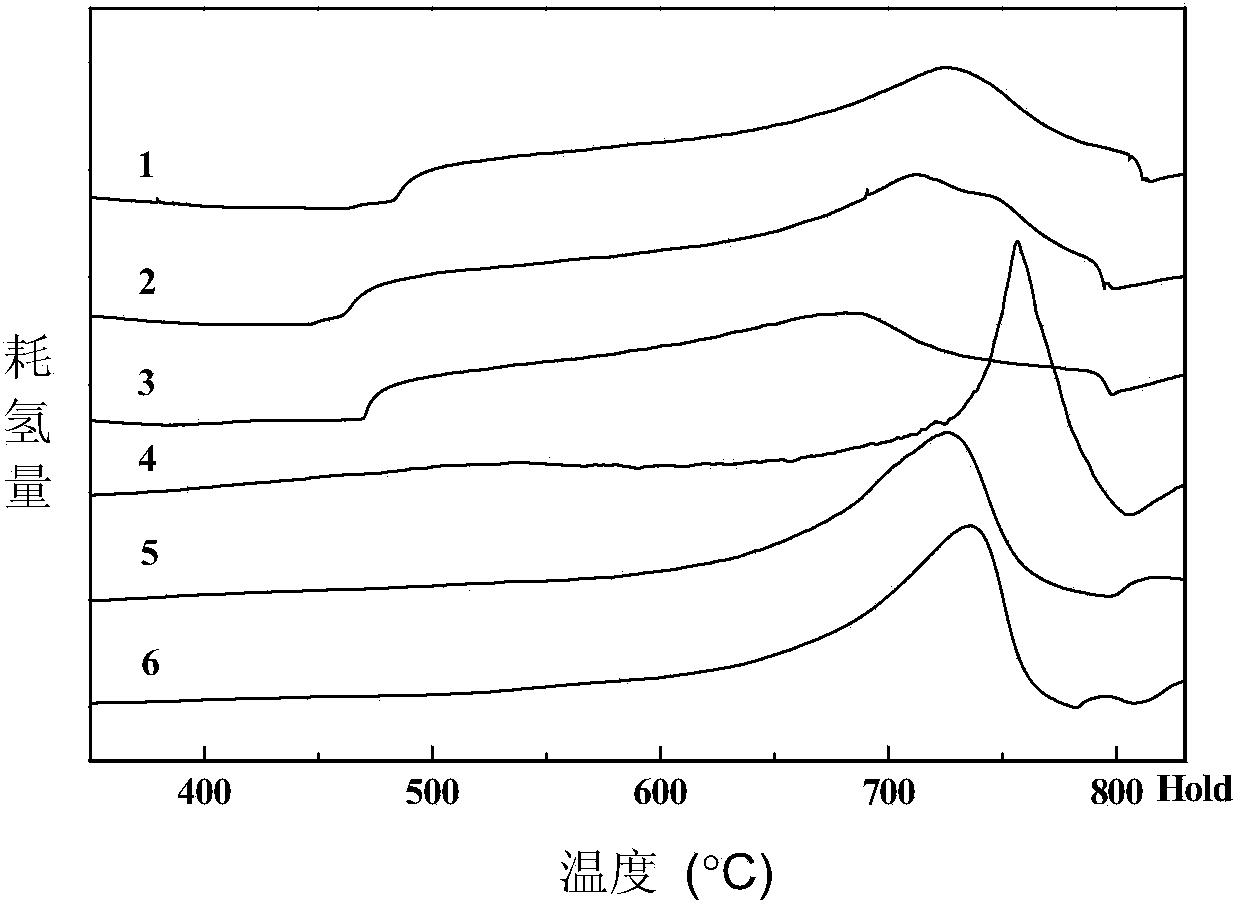

Image

Examples

Embodiment 1

[0020] The mixed solution of 4.8g vanadium pentoxide and 72ml benzyl alcohol and isobutanol (1:1 volume ratio) was refluxed at 140°C for 6 hours, and 6.69g concentrated phosphoric acid with a concentration of 85% by mass was added, and then refluxed for 6 hours , the obtained dark blue suspension mixture was filtered, the solid was washed with acetone, and dried at 100° C. for 24 hours to obtain a catalyst precursor. The dried catalyst was pressed into tablets and crushed to obtain 60-80 mesh particles for activity testing.

[0021] Take 0.5g of the above catalyst, and carry out the continuous reaction of glycerol dehydration to produce acrylic acid in a fixed-bed reactor. The meter is passed into the catalyst bed, the reaction material is 36.5% glycerol aqueous solution, and the liquid space velocity is 4h -1 . Sampling and chromatographic analysis after 2 hours showed that the conversion rate of glycerin was 72.0%, the yield of acrolein was 23.3mol%, and the generation rat...

Embodiment 2

[0023] A mixed solution of 4.8g of vanadium pentoxide and 72ml of benzyl alcohol and isobutanol (1:1 by volume) was refluxed at 140°C for 6 hours, 2.1g of PEG6000 was added, and after one hour, 6.69g of PEG6000 was added with a mass percent concentration of 85 % concentrated phosphoric acid, and then reflux for 6 hours, filter the resulting dark blue suspension mixture, wash the solid with acetone, and dry at 100°C for 24 hours to obtain the catalyst and press it into tablets and crush it to obtain 60-80 mesh particles, which are used for active test.

[0024] Take 0.5g of the above catalyst, and carry out the continuous reaction of glycerol dehydration to produce acrylic acid in a fixed-bed reactor. The meter is passed into the catalyst bed, the reaction material is 36.5% glycerol aqueous solution, and the liquid space velocity is 4h -1 . After 2 hours, sampling and chromatographic analysis showed that the conversion rate of glycerin was 93.3%, the yield of acrolein was 18....

Embodiment 3

[0026] 4.8g of vanadium pentoxide and 72ml of benzyl alcohol were refluxed at 140°C for 6 hours, 2.1g of PEG6000 was added, and after one hour, 6.69g of concentrated phosphoric acid with a concentration of 85% by mass was added, and then refluxed for 6 hours, and the obtained dark blue suspension The turbid mixture was filtered, the solid was washed with acetone, and dried at 100° C. for 24 hours to obtain a catalyst precursor. The obtained sample was pressed into tablets and crushed to obtain 60-80 mesh particles for activity testing.

[0027] Take 0.5g of the above catalyst, and carry out the continuous reaction of glycerol dehydration to produce acrylic acid in a fixed-bed reactor. The meter is passed into the catalyst bed, the reaction material is 36.5% glycerol aqueous solution, and the liquid space velocity is 4h -1 . Sampling chromatographic analysis after 2h showed that the conversion rate of glycerin was 88.7%, the yield of acrolein was 23.3%, and the generation rate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap