Workpiece alignment mechanism of turning lathe

A workpiece and lathe technology, applied in the field of lathe workpiece alignment mechanism, can solve the problems of high experience requirements for lathe operators and time-consuming coaxiality, and achieve the effects of no influence on normal cutting of lathes, good adaptability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

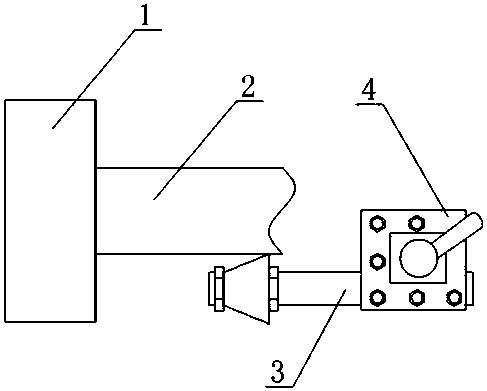

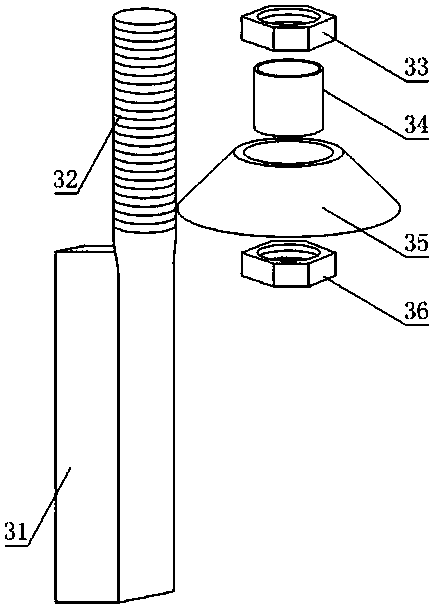

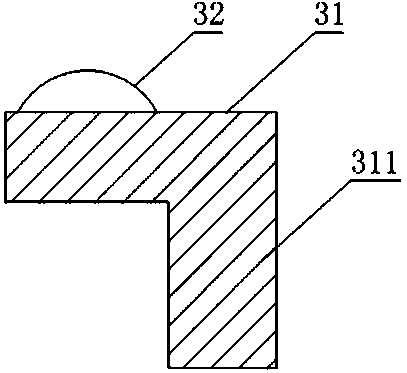

[0023] like Figure 1 to Figure 3 As shown, a lathe workpiece alignment mechanism includes an alignment body 3, the alignment body 3 includes a mounting block 31, an alignment wheel rod 32 and an alignment wheel 35, the installation block 31 is flat, The alignment wheel rod 32 is round rod shape, and one end of the mounting block 31 is fixedly connected with the end of the alignment wheel rod 32, and the length direction of the installation block 31 is parallel to the axial direction of the alignment wheel rod 32, and the alignment wheel 35 is a cone In the form of a platform, the alignment wheel 35 is provided with a through hole along its height direction, and the through hole and the alignment wheel bar 32 form a clearance fit, and the center line of the alignment wheel 35 and the alignment wheel bar 32 is collinear.

[0024] Since the present invention will form a larger interaction force between the mounting block 31 and the knife rest 4 during use, in the present embodim...

Embodiment 2

[0026] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, it also includes a shaft sleeve 34, an outer limit nut 33 and an inner limit nut 36. The alignment wheel rod 32 is an externally threaded rod, and the shaft sleeve 34 is nested on the alignment wheel rod 32. And the positive and negative deviation of the inner diameter of the shaft sleeve 34 and the outer diameter of the alignment wheel rod 32 is within 0.2 millimeters, the alignment wheel 35 is nested on the shaft sleeve 34, and the alignment wheel 35 forms a gap with the shaft sleeve (34) Cooperate, the inner diameter of the alignment wheel 35 through holes is 0.4-0.8 mm larger than the outer diameter of the axle sleeve 34, the outer limit nut 33 and the inner limit nut 36 are threaded with the alignment wheel rod 32, and the alignment The wheel 35 is located between the outer stop nut 33 and the inner stop nut 36 .

[0027] In the above settings, the alignment ...

Embodiment 3

[0029] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, since it is very easy to realize that the turning tool mounting surface on the tool rest 4 is parallel to the lathe spindle, in order to make the radial direction of the alignment wheel 35 and the plane where the radial direction of the workpiece 2 are parallel to each other, a plate-shaped stop is also included. The stopper 311 , the limit stopper 311 is fixedly connected to one side of the installation block 31 , and the limit stopper 311 is perpendicular to the installation block 31 . Specifically, a right-angle included angle is formed between the limit block 311 and the mounting block 31. When the present invention is installed on the tool rest 4, the right-angle included angle and the right angle of the turning tool installation station on the tool rest 4 are in good contact with each other. close, that is, it can ensure that the mounting block 31 is parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com