Drive axle semi-shaft

A drive axle and wheel hub technology, applied in the field of drive axle half shafts, can solve the problems of inconvenient use and maintenance of parts, complicated manufacturing process, and high processing difficulty, and achieve the effects of convenient connection, convenient manufacturing and processing, and low manufacturing and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

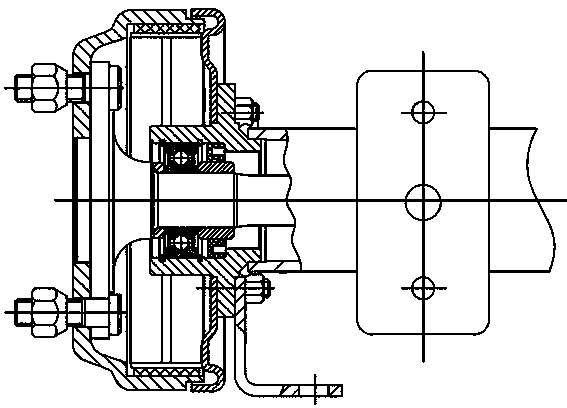

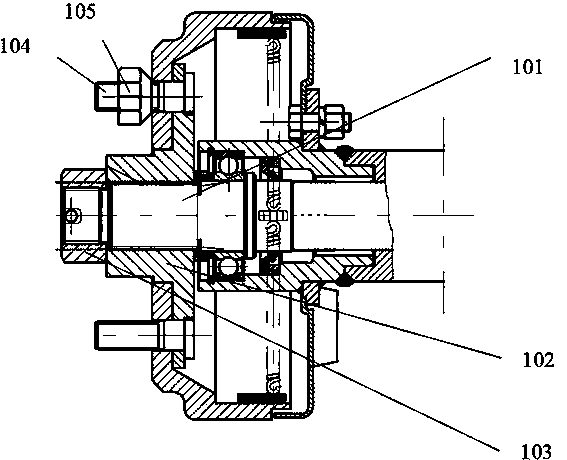

[0013] this invention It includes a hub 102 and a half shaft 101, the half shaft 101 is sleeved with the hub 102, the hub 102 and the half shaft 101 are connected by splines, and the outer end of the half shaft 101 is formed with a thread pair that matches the nut 103 , the hub 102 is locked from one end by a nut 103, and the hub 102 is locked and connected to the semi-shaft 101 without a flange, which is used to transmit torque and install the structure of the rim tire; the outer circumference of the hub 102 and the semi-axis 101 A step matching with the rim is formed in the vertical direction, and the side wall formed by the step is in contact with the inner wall of the rim, and the inner wall of the rim and the side wall of the hub 102 are pressed, connected and installed as a whole with bolts 104 and nuts 105 .

[0014] Bolt mounting holes are provided at positions corresponding to the mounting holes of the wheel hub 102 for mounting bolts 104 that compress the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com