Plug-in-type column pile

A plug-in, post-piling technology, applied in the field of post-piling, can solve the problems of poor site utilization, inability to produce specifications, and quantity adjustment and storage position, and achieve reliable post-piling, simple coaxial plug-in structure, and stable quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

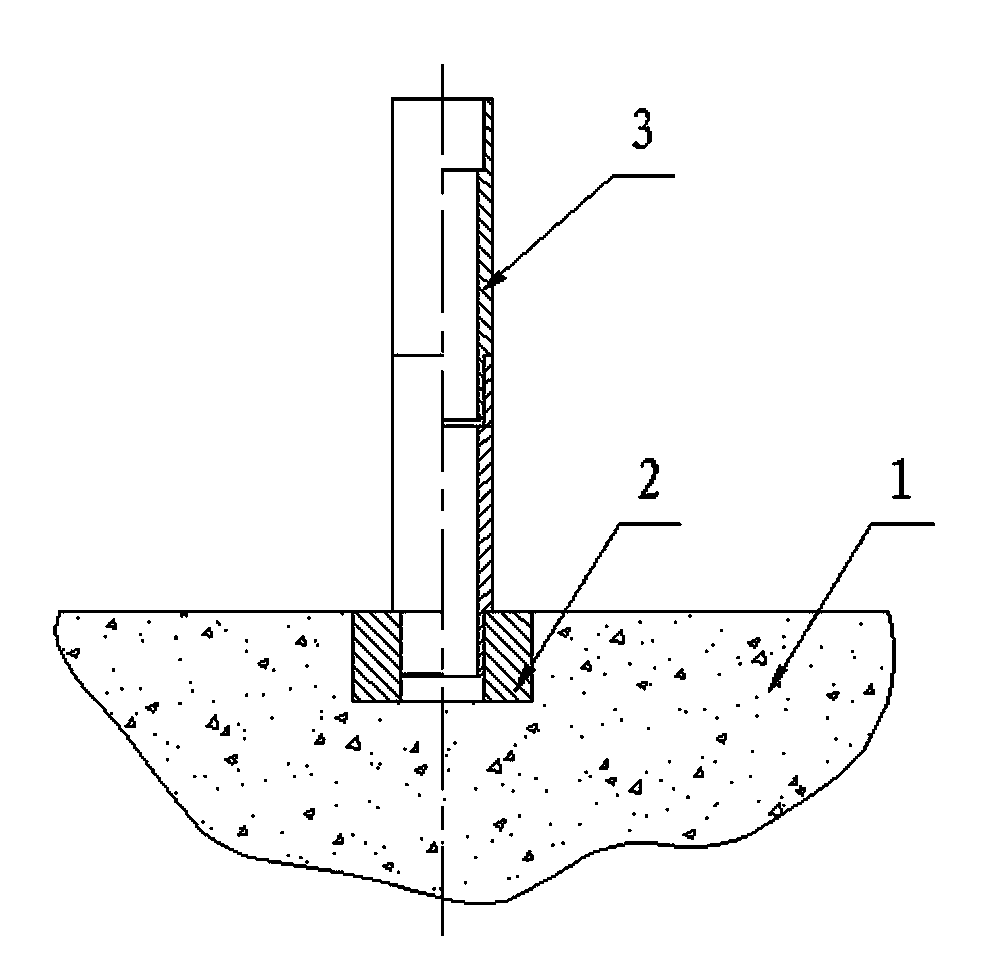

Embodiment 1

[0015] This embodiment is used to stack 5 layers of DN600mm polyethylene pipes. Because the diameter of the pipe is relatively thick, the height of the stack is high, and the weight is heavy, it is selected to use 6 pillars 3 to be plugged into one body, and each pillar 3 is 50mm long. , outer diameter Φ100mm, interface and joint diameter Φ90mm. In order to ensure that each post 3 is inserted in place, the depth of the inner hole of the casing 2 and the depth of the interface of the post 3 are made to be 150 mm, and the joint length of the matching post 3 is 140 mm. Under this size condition, the inserted column pile 3 forms a pile and is positioned in the casing 2, which is mechanically connected, and the limit is reliable, which fully meets the limit requirements for stacking 5-layer pipes. In addition to simple structure and easy plugging, the present invention has greater flexibility. When the production workshop needs to adjust the temporary stacking place of products, th...

Embodiment 2

[0017] In this embodiment, the DN100mm polyethylene pipe used for stacking is relatively small in diameter and light in weight, so the requirements for the strength of the pile 3 are also small, so the pile 3 with an outer diameter of Φ50mm can meet the normal pile requirements. High limit requirements. The rest of the structure of the pile 3 is the same as that of Example 1, the main size changes are that the total length is changed to 300mm, the inner diameter of the upper end joint and the outer diameter of the lower end joint are equal to Ф40mm, the depth of the inner hole of the casing 2 and the joint depth of the pile 3 are 100mm , the joint length of the column pile 3 is 90mm. The application effect of this embodiment is similar to that of Embodiment 1.

[0018] In addition to being applied in polyethylene pipe production lines, the present invention can also be used for on-site stacking of products in production lines such as steel pipes, copper pipes, and aluminum pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com