Method for settling vanadium by using acidic vanadium solution

A vanadium liquid and acidic technology, which is applied in the field of preparing vanadium pentoxide, can solve the problems of increased production costs, and achieve the effect of saving working hours and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

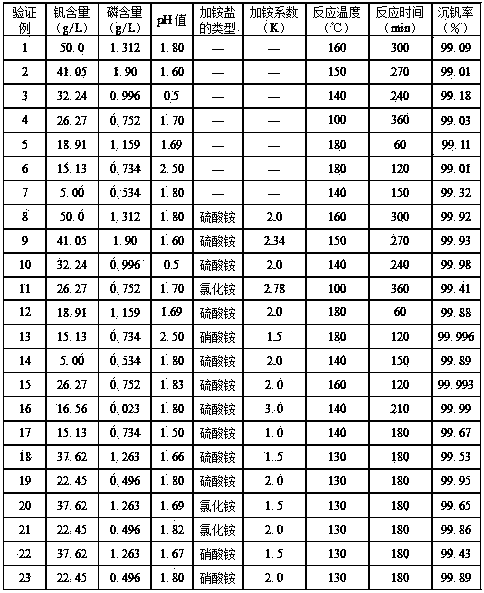

[0012] The invention discloses a method for precipitating vanadium by using acidic vanadium liquid. The method uses the acidic vanadium liquid as the stock solution to deposit vanadium. In the present invention, the vanadium precipitation process is carried out in a hydrothermal reaction kettle; the vanadium content in the acidic vanadium solution is 5.00-50.00g / L, and the impurity phosphorus content is 0.02-1.90g / L; the steps are as follows :

[0013] (1) Adjust the pH value of the acidic vanadium solution to 0.5-2.5 at one time (those skilled in the art know that when adjusting the pH value of the acidic vanadium solution, sulfuric acid——H 2 SO 4 ), and then placed in a closed hydrothermal reactor;

[0014] (2) Raise the temperature of the acidic vanadium solution to 100°C to 180°C to carry out the vanadium precipitation reaction (the reaction time should obviously be controlled by the amount of vanadium in the acidic vanadium solution and the reaction temperature, usually...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap