A hot rolling process method for refining grains of high manganese austenitic steel

A technology of austenitic steel and process method, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of insignificant grain refinement effect, difficulty in multiple recrystallization, and narrow deformation temperature range. , to achieve the effect of small grain size, small rolling deformation resistance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

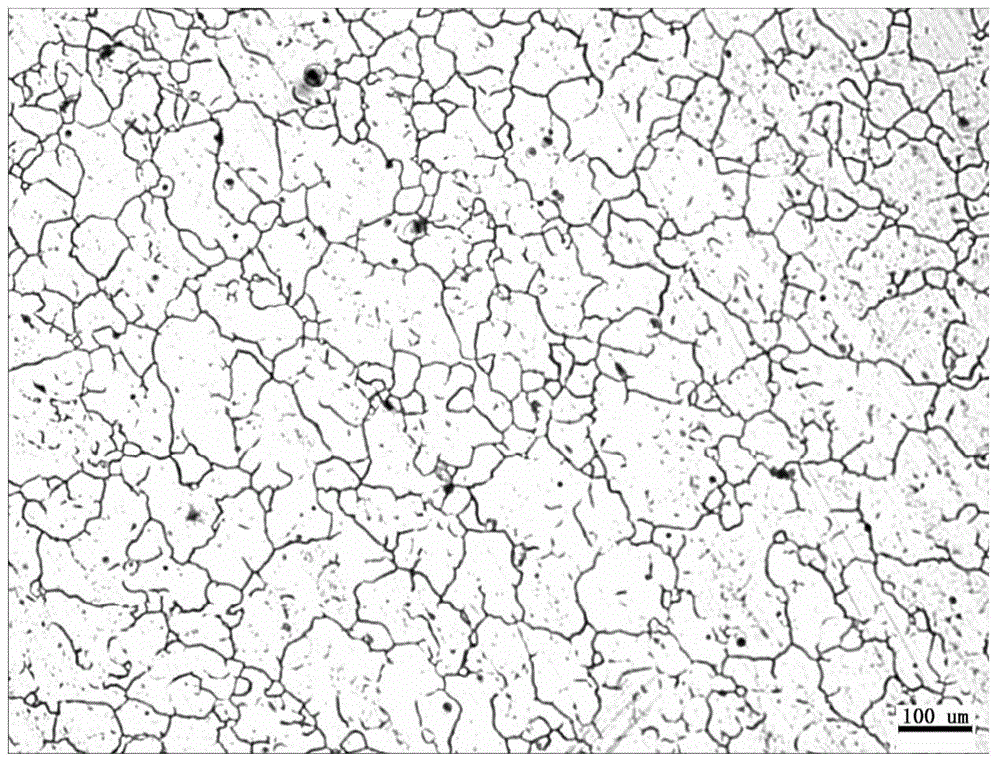

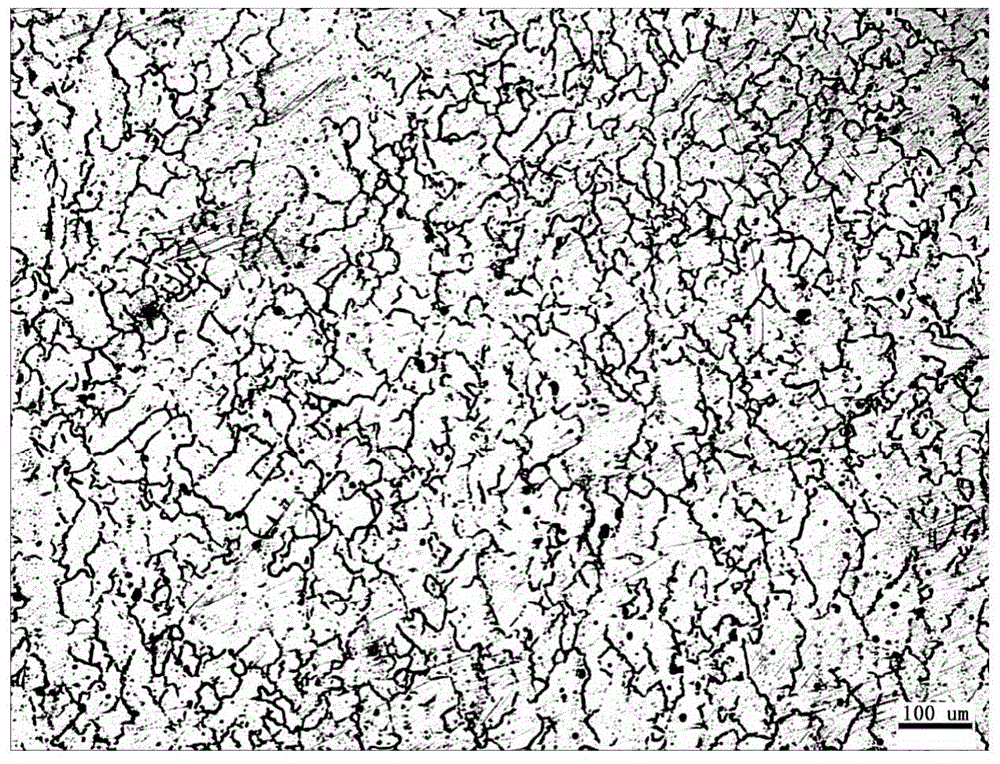

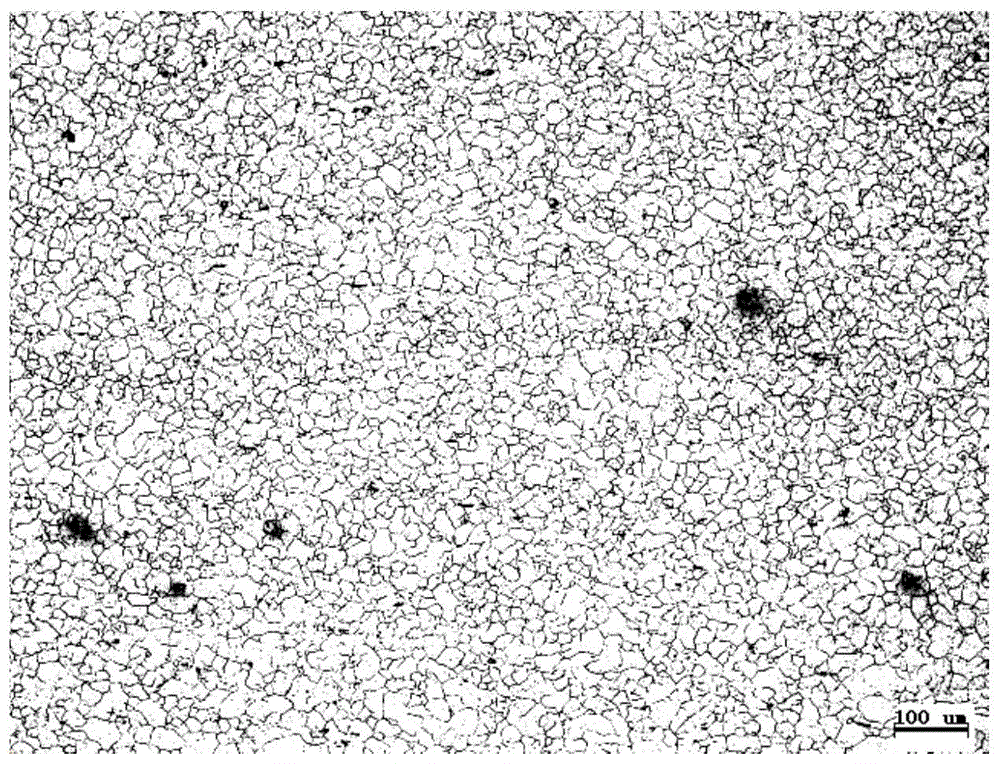

[0023] The 24Mn1Cr2Si0.1N high manganese austenitic steel with a thickness of 10mm was heated to 1200°C at a heating rate of 100°C / min, kept for 1 hour, and then cooled to 1050°C to start the first rolling pass. Rolling parameters For: deformation rate 0.006s -1 , The reduction is 20%. After an interval of 5s, the second rolling pass is carried out, and the rolling parameters are: deformation rate 0.2s -1 , The reduction is 40%. The third rolling pass is carried out after an interval of 5s, and the rolling parameters are: deformation rate 2s -1 , The reduction is 30%. The final rolling temperature is controlled above 950°C, and water is sprayed rapidly after rolling for cooling. The average grain size obtained by the above three-pass rolling is about 5 μm (such as image 3 shown), which is similar to the structure of the unrolled sheet (such as figure 1 As shown), the grains are significantly refined; and compared with the structure of one-time rolling in the prior art (...

Embodiment 2

[0025] The Fe-38Mn high-manganese austenitic steel with a thickness of 10mm was heated to 1250°C at a heating rate of 100°C / min, kept for 1 hour, and then cooled to 1000°C to start the first rolling pass. Rolling parameters For: deformation rate 0.007s -1 , The reduction is 20%. After an interval of 5s, the second rolling pass is carried out, and the rolling parameters are: deformation rate 0.4s -1 , The reduction is 40%. The third rolling pass is carried out after an interval of 5s, and the rolling parameters are: deformation rate 4s -1 , The reduction is 30%. The final rolling temperature is controlled above 950°C, and water is sprayed rapidly after rolling for cooling. The average grain size obtained by the above three-pass rolling is about 8 μm (such as Figure 5 shown), which is similar to the structure of the unrolled sheet (such as Figure 4 As shown), the grains are significantly refined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com