Safety production tubular column for same-well production and injection in offshore oilfield

A technology of production and injection in the same well and safe production, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problem of easy sand production in offshore sand production reservoirs, no safe production control technology, and application Problems such as limited scope, to achieve the effect of high utilization efficiency, high success rate, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

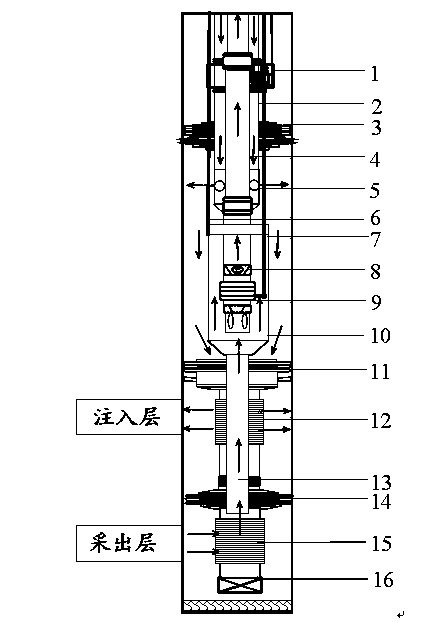

[0019] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0020] according to figure 1 As shown, a safe production string for the production and injection of the same well in an offshore oilfield includes a downhole double-control safety valve 1, a large-diameter outer pipe 2, a through-type expansion packer 3, a small-diameter inner pipe 4, a diverter device 5, and an exhaust Pipe 6, cable crossing hanger 7, check valve 8, electric pump unit 9, volume cylinder 10, suspension packer 11, liquid injection layer sand filter pipe 12, long sealing cannula 13, filling sand control packer 14, The sand filter pipe 15 and the plug 16 of the fluid collection layer.

[0021] The suspension packer 11 is installed on the upper end of the sand filter pipe 12 of the liquid injection laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com