Straight-through type narrow-pipe wind collecting wind power generation system

A wind power generation system, straight-through technology, applied to wind power generator components, wind power engines, wind power generators at right angles to the wind direction, etc., can solve the problem of affecting wind energy utilization and power generation efficiency, reducing pressure and wind speed, reducing air pressure difference, etc. problems, to achieve the effect of improving wind energy utilization and power generation efficiency, increasing the degree of shrinkage, and increasing the sweeping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

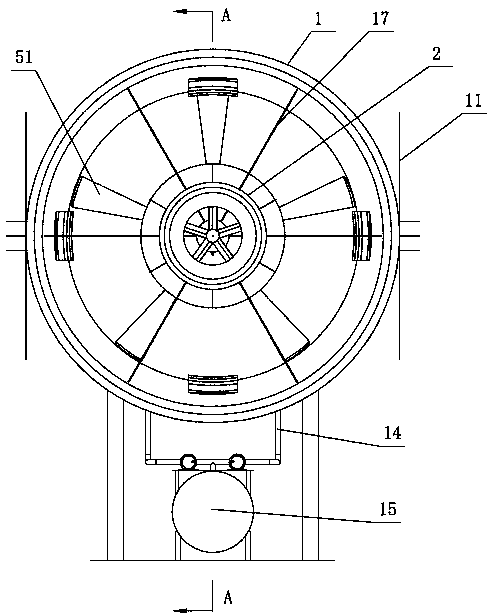

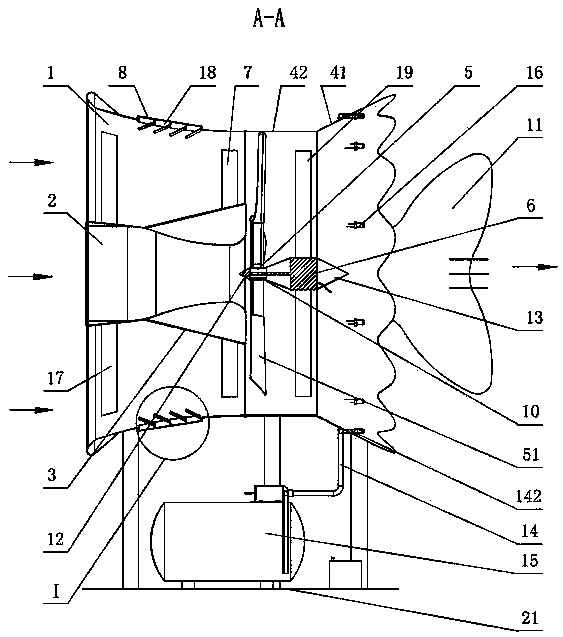

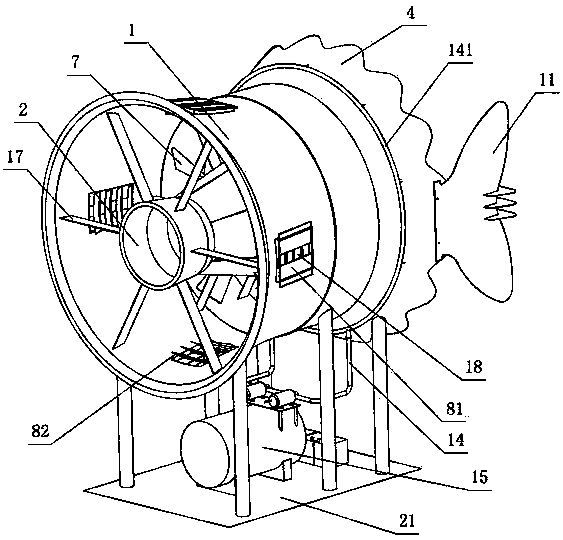

[0042] See figure 1 , figure 2 , image 3 , the present invention includes an outer narrow tube 1, an inner narrow tube 2 is integrally sleeved in the outer narrow tube 1, a taper sleeve 3 is fixedly connected to the outer peripheral surface of the inner narrow tube 2, and the wide head end of the taper sleeve 3 is located at the outer narrow tube 1 and the tapered sleeve 3 is provided with a guide vane 7, the inner narrow tube 2 and the tapered sleeve 3 are fixedly supported in the outer narrow tube 1, specifically, the front outer peripheral surface of the inner narrow tube 2 and the inner peripheral surface of the outer narrow tube 1 A plurality of first support plates 17 are connected between them, and a plurality of guide vanes 7 are connected between the outer peripheral surface of the taper sleeve 7 and the inner peripheral surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com