Maintenance and replacement device for part of pitch system and wind turbine generator set

A pitch system and component technology, applied in wind turbine components, wind turbines, wind power generation, etc., can solve the problems of inability to rely on manpower to disassemble, transport and replace, increase the weight of the pitch drive, and take a long time. Simple and feasible effect of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

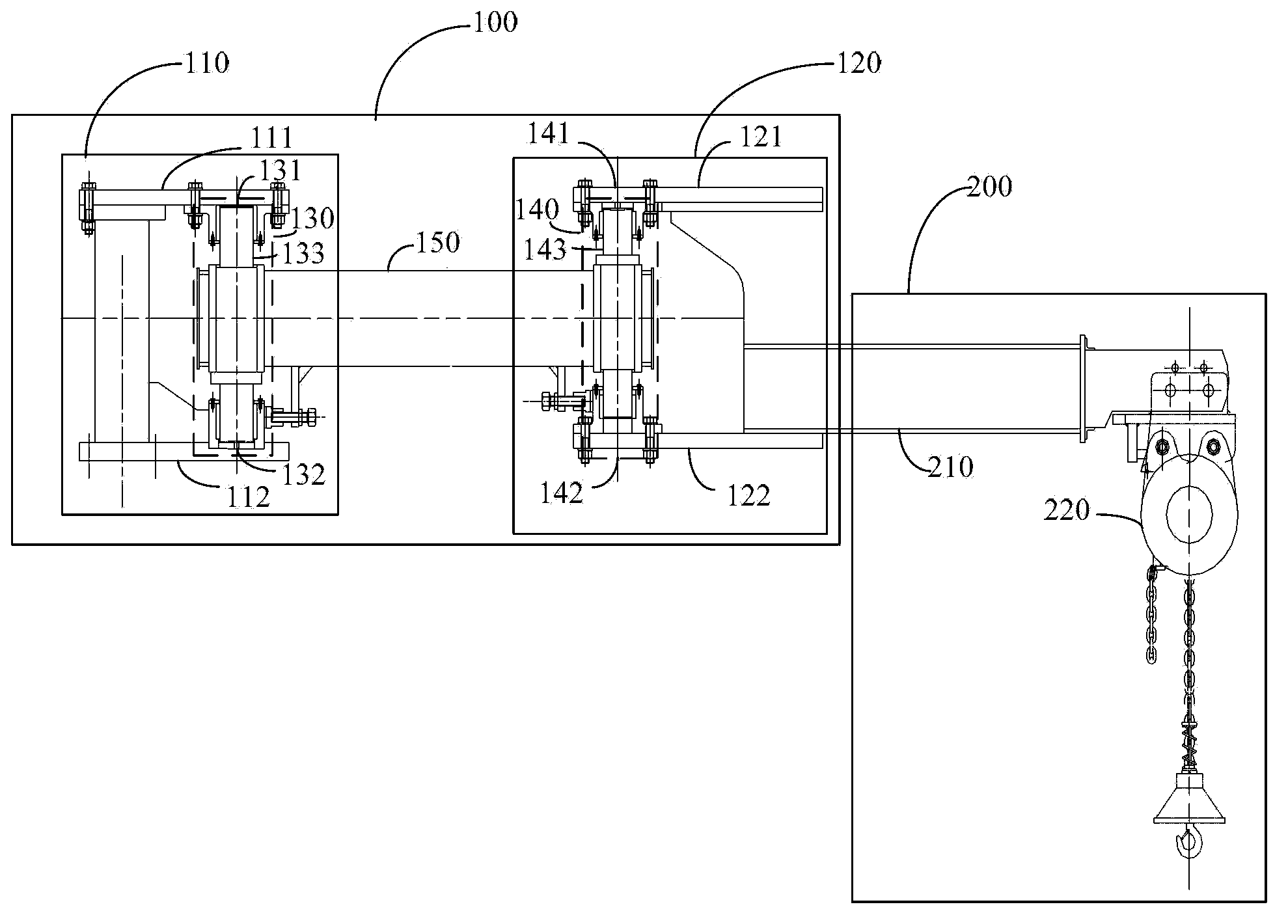

[0025] The maintenance and replacement device for pitch system components provided by the present invention may include a rotating drive device and an operating arm connected to each other, and the rotating drive device may be fixed on the top of the nacelle frame; wherein, the rotating drive device is used to drive the above operating arm to rotate; The operating arm is used to suspend the pitch system components out of the opening in the hub wall and is rotated above the nacelle by the rotary drive.

[0026] Specifically, when the components of the pitch system in the hub of the high-power unit fail, the operator needs to enter the interior of the hub, remove the fixed ends of the components of the pitch system from the hub, and drive the pitch drive of this embodiment The maintenance and replacement device is fixed on the top of the nacelle frame by bolts, and the components of the pitch system are suspended out of the opening of the hub wall by the operating arm, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com