High temperature resistance large load fiber sensing device

A technology of optical fiber sensing and large load, which is applied in the direction of measuring devices, instruments, weighing, etc., can solve the problems of sensing devices not durable, molten steel splashing, hidden dangers, etc., to simplify the installation and debugging procedures, and reduce processing and production costs , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

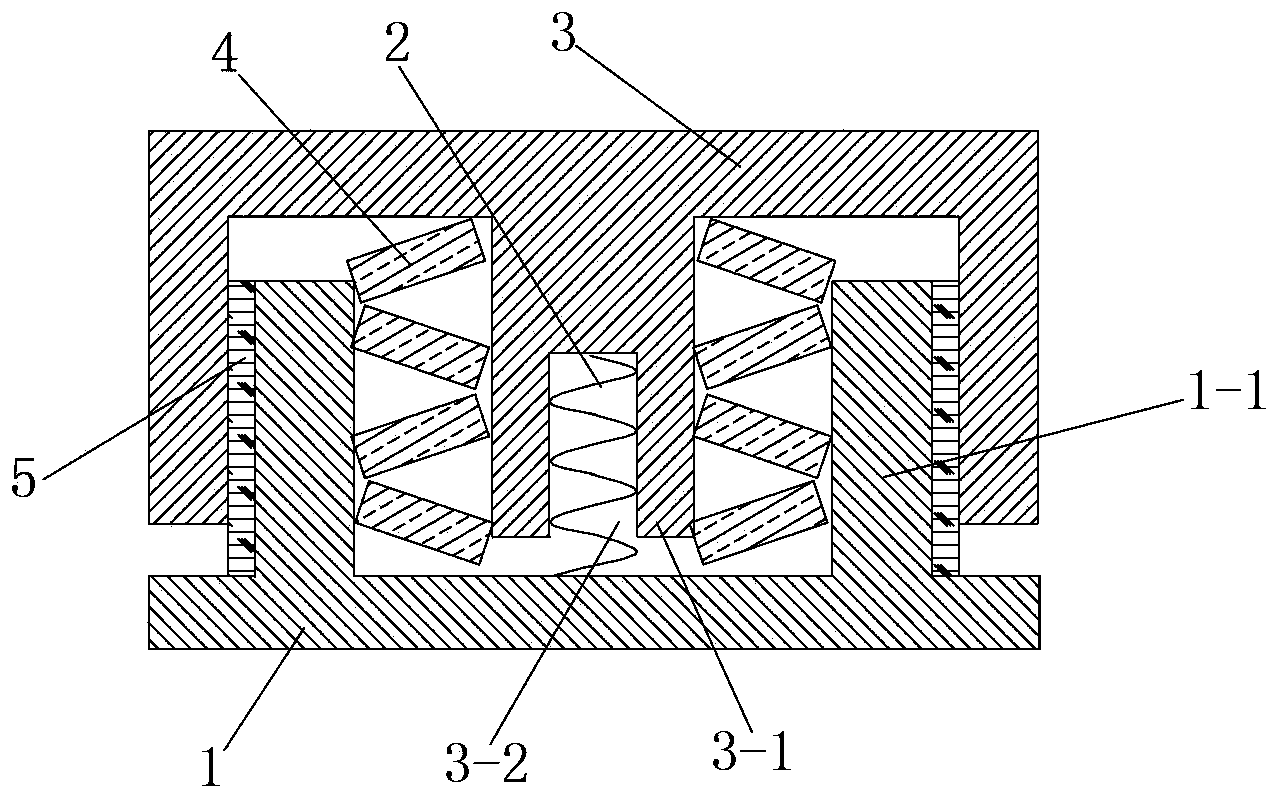

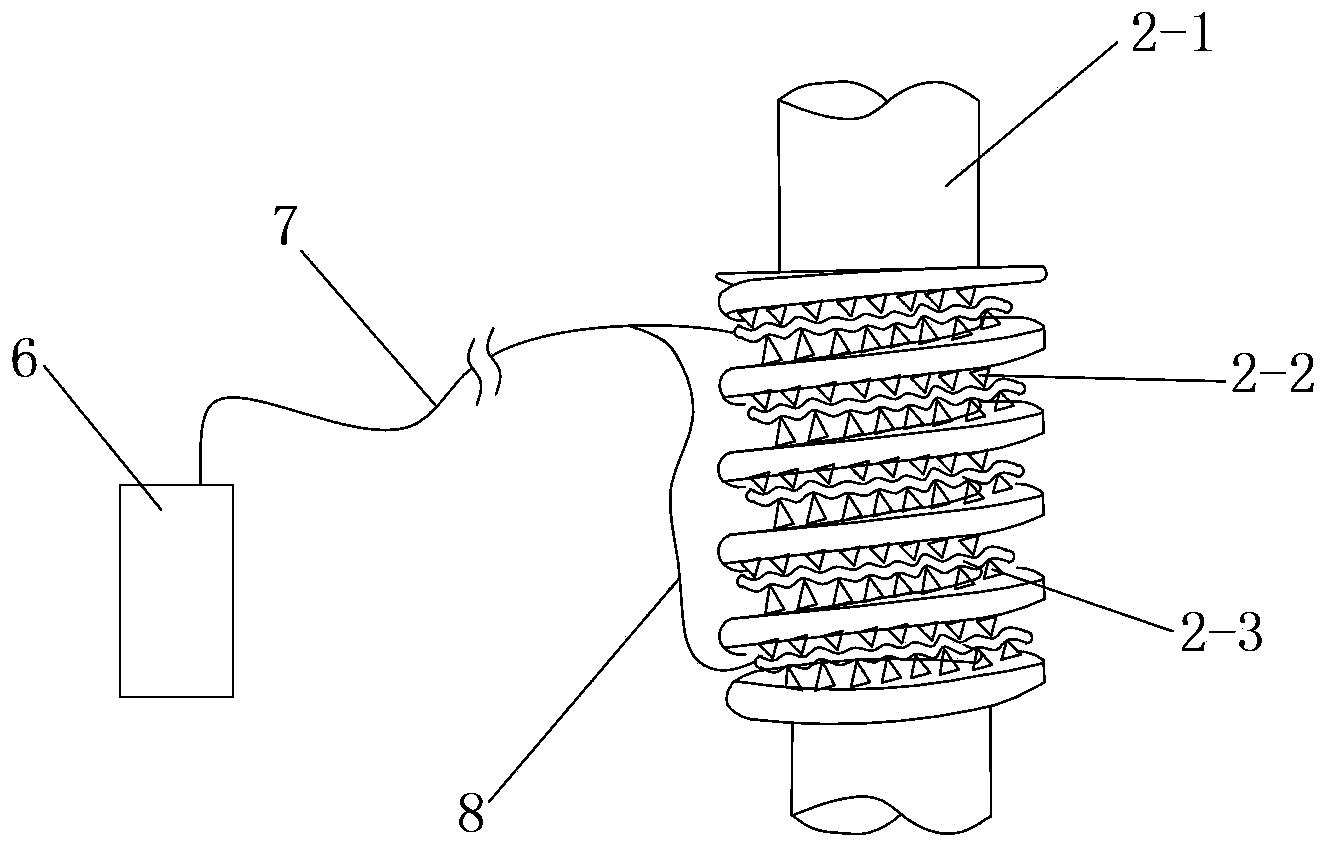

[0022] like figure 1 and figure 2 A high-temperature-resistant and heavy-load optical fiber sensing device shown includes a base 1 and an upper cover 3 covered on the base 1. A sleeve 1-1 is integrally formed on the base 1. The upper cover The bottom surface of 3 is provided with a connecting column 3-1, and the connecting column 3-1 is integrally formed with the upper cover 2, and the connecting column 3-1 is located inside the sleeve 1-1, and the lower part of the connecting column 3-1 The end face is provided with a vertically arranged blind hole 3-2, and the optical fiber bending sensing unit 2 is arranged in the blind hole 3-2, and the optical fiber bending sensing unit 2 includes a curved bracket 2-1, and the curved The upper end of the bracket 2-1 abuts against the top surface of the blind hole 3-2, the lower end of the curved bracket 2-1 is fixed on the top surface of the base 1, and the opposite sides of the curved bracket 2-1 A plurality of A-side deformed teeth 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com