A method for online moisture detection in continuous grain drying process

A detection method and grain drying technology, which is applied in the direction of static material dryers, solid material drying, local stirring dryers, etc., can solve the problems of low grain moisture detection accuracy, large monitoring errors, and difficult elimination of dynamic errors, etc., and achieve the goal of overcoming Effects of temperature and humidity sensitivity issues, improved accuracy and stability, and avoidance of major defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

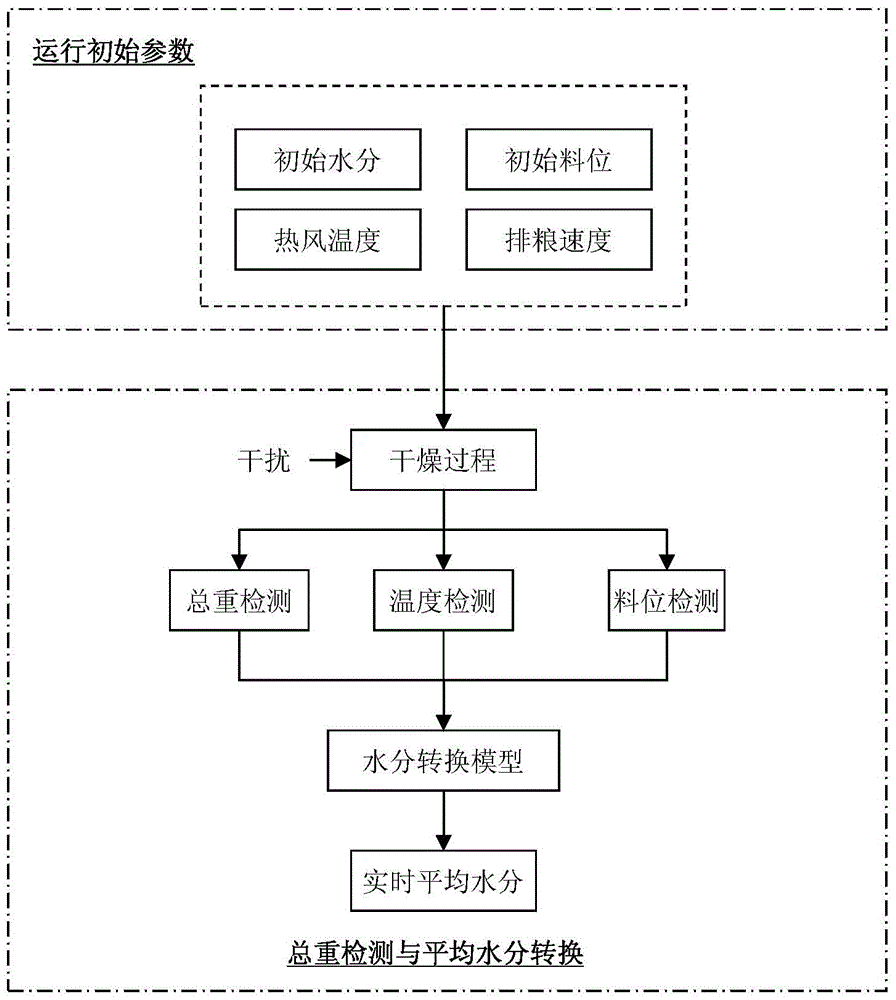

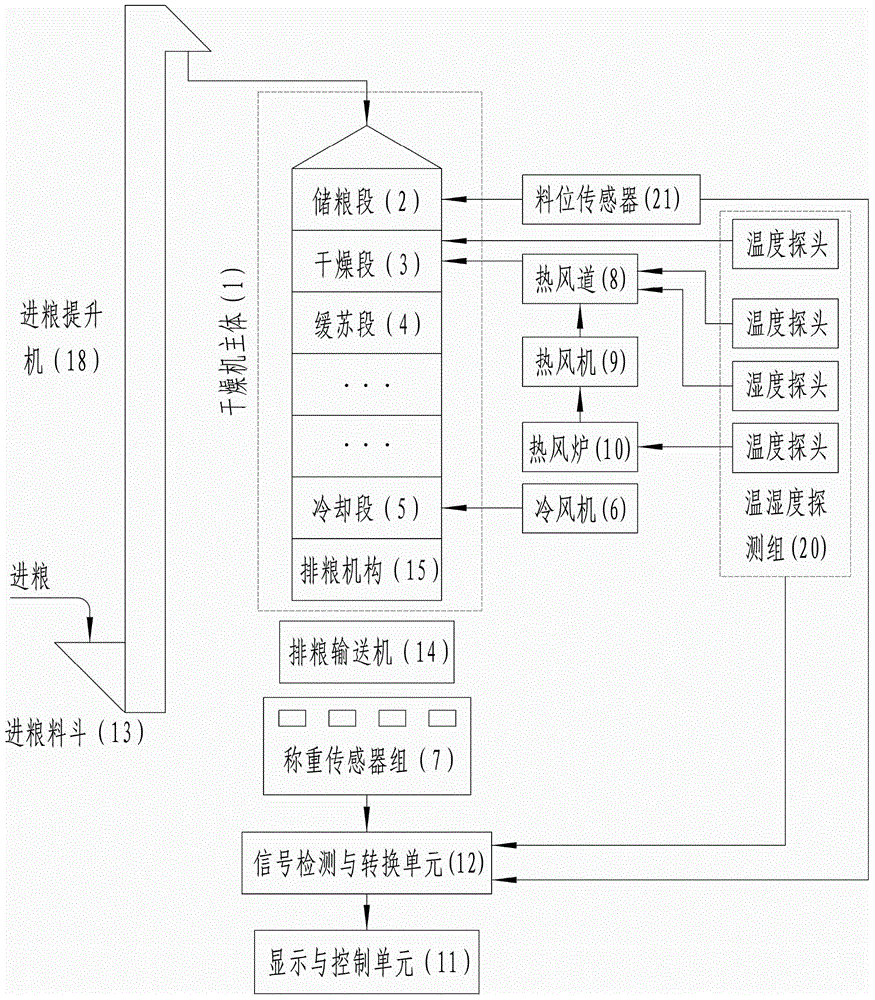

[0023] see image 3 and Figure 4 , a continuous grain drying automatic operation system includes a dryer main body 1, a hot air duct 8, a hot air blower 9, a cold air blower 6, a hot blast stove 10, a grain feeding hoist 18, a load cell group 7 for the total weight of the dryer, and a signal detection And conversion unit 12, control display unit 11, temperature and humidity probe group 20, material level sensor 21, grain feeding chute 22.

[0024] During the drying operation, the grain to be dried is conveyed into the drying main body 1, the total weight sensor group 7 of the dryer is placed at the bottom of the column of the base of the main body 1 of the dryer or on the column, and the total weight of the dryer group 7 is connected with the signal detection and The conversion units 12 are connected together, and the signal detection and conversion unit 12 is connected with the control display unit 11 . The dryer total weight sensor group 7 is used to detect the total weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com