Ultrasonic non-destructive testing method for measuring circumference residual stress at gear root

A technology of residual stress and measurement method, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of practical application limitations, low accuracy, and many influencing factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

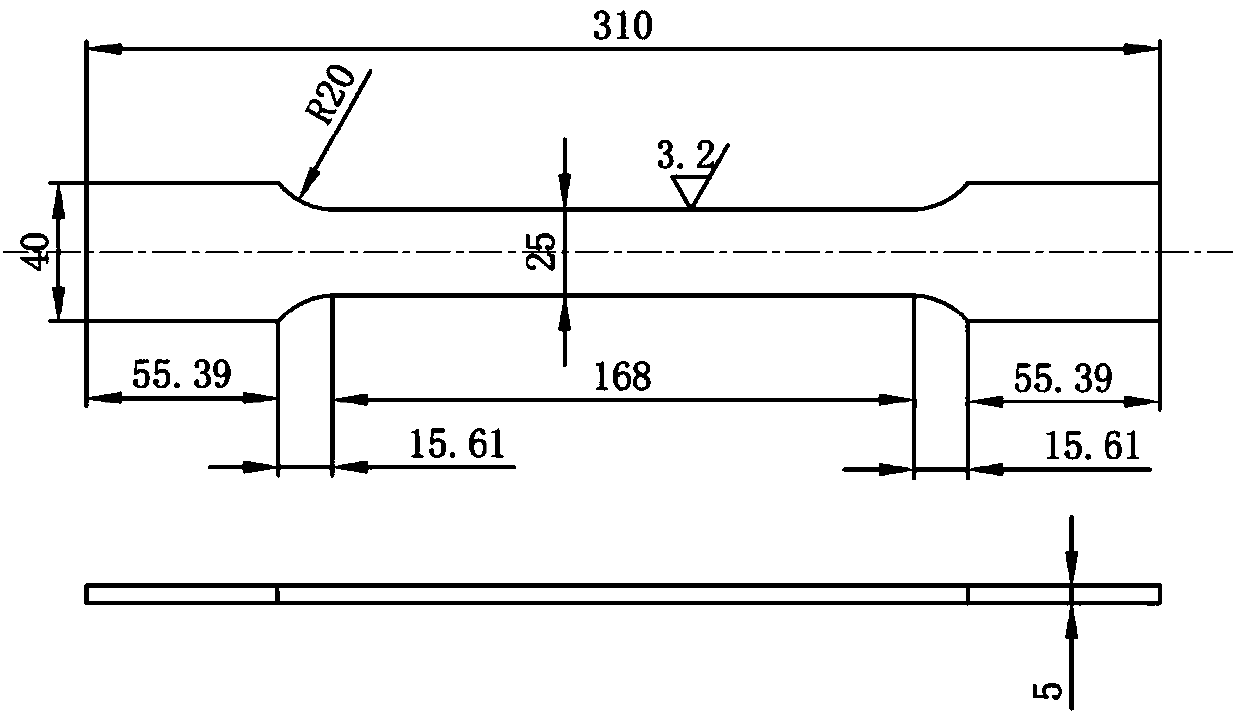

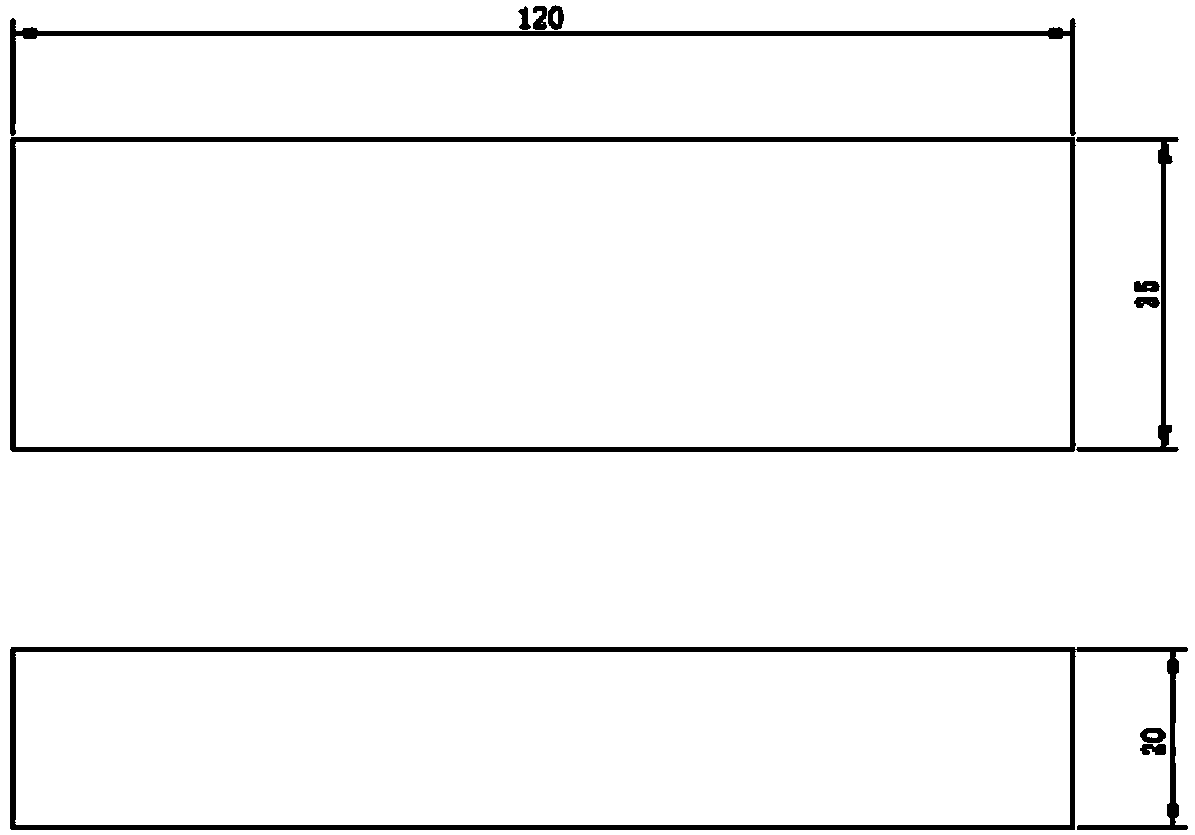

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is described in detail below:

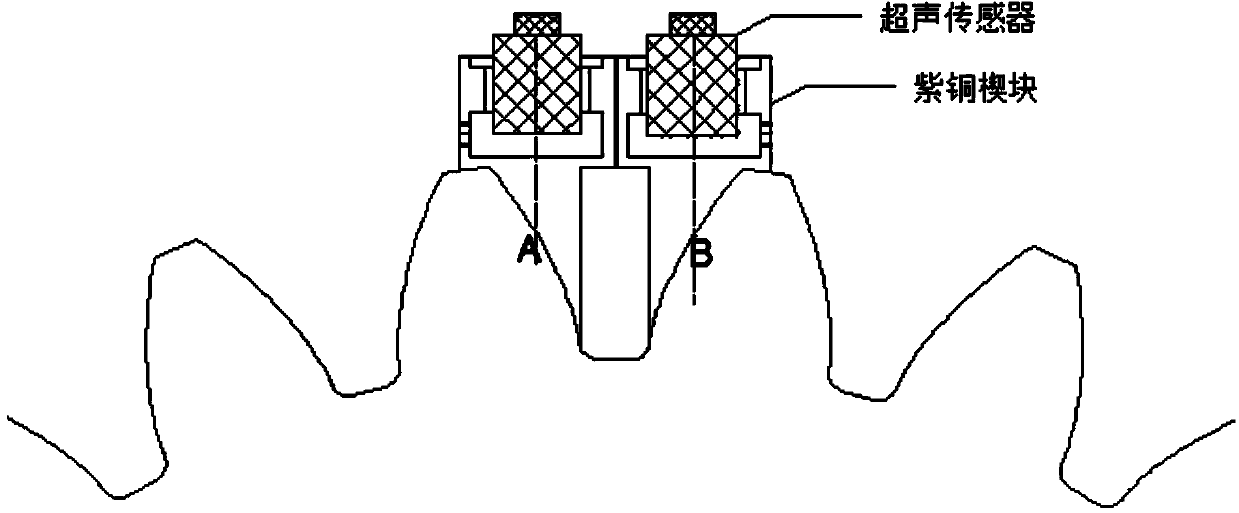

[0015] 1. L CR wave excitation

[0016] According to Snell's law, when the ultrasonic longitudinal wave propagates from the slower acoustic wedge to the faster gear material, refraction will occur. When the longitudinal wave refraction angle is equal to 90°, the corresponding incident angle is called the first critical angle. Calculate The formula is shown below.

[0017] θ cr = sin - 1 ( V / V 2 )

[0018] In the formula:

[0019] V 1 —propagation speed of ultrasonic longitudinal wave in medium with slow wave velocity (m / s);

[0020] V 2 — Propagation speed of ultrasonic longitudinal wave in medium with faster wave velocity (m / s).

[0021] θ cr - the first critical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com