Thin Fresnel lens with a short focal length

A Fresnel lens and short focal length technology, applied in the field of optical instruments, can solve the problems of increasing reflection loss, increasing system size and cost, and increasing focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

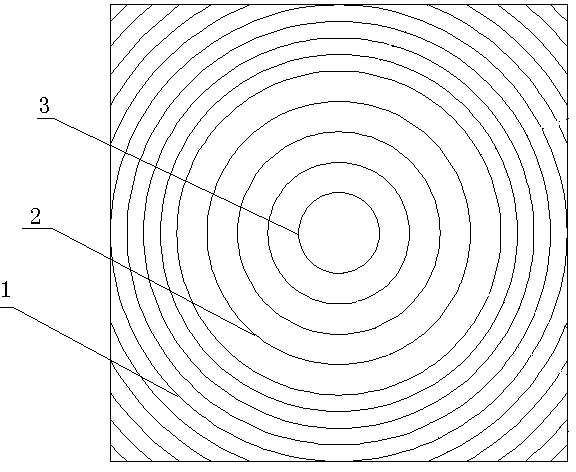

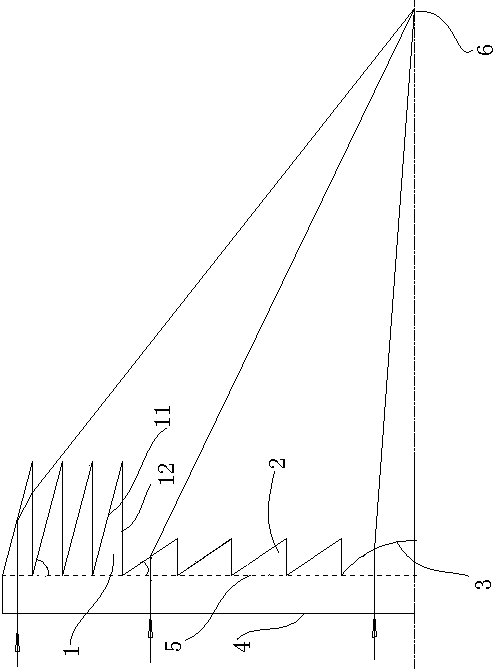

[0021] figure 1 The planar layout structure of the present invention is shown, the overall shape of the lens is square, and a plano-convex lens protrusion 3 is arranged in the middle, and a refraction protrusion 2 is arranged on the periphery of the plano-convex lens protrusion 3, and a reflection protrusion 1 is arranged on the periphery of the refraction protrusion 2, wherein The number of rings about the refraction protrusions 2 and the reflection protrusions 1 can be determined according to actual needs. In order to realize the short focal length of the present invention, in this embodiment, a reflective convex structure is adopted on the periphery of the lens. combined with figure 2 , to further illustrate the lens structure provided with reflective protrusions 1 . figure 2 is a cross-sectional view of the lens structure, showing only the upper half. Wherein, it includes a base plane 4 and a converging surface 5 parallel to each other, on which a converging protrusio...

Embodiment 2

[0023] Compared with Embodiment 1, this embodiment differs in that a reflective film is provided on the inclined surface 11 of the reflective protrusion 1, and the light is reflected on the reflective film on the inclined surface 11. The slope requirement is not high, even if the incident angle is smaller than the critical angle of total reflection, it can still play a light-gathering effect and shorten the focal length.

Embodiment 3

[0025] Compared with Embodiment 1, this embodiment differs in that the overall shape of the lens is circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com