Small directional high-flux neutron generator

A neutron generator and high-throughput technology, applied in nuclear technology and application fields, can solve problems such as poor collimation performance, high cost, and technical complexity, and achieve the effect of unlimited deposition power and high neutron yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

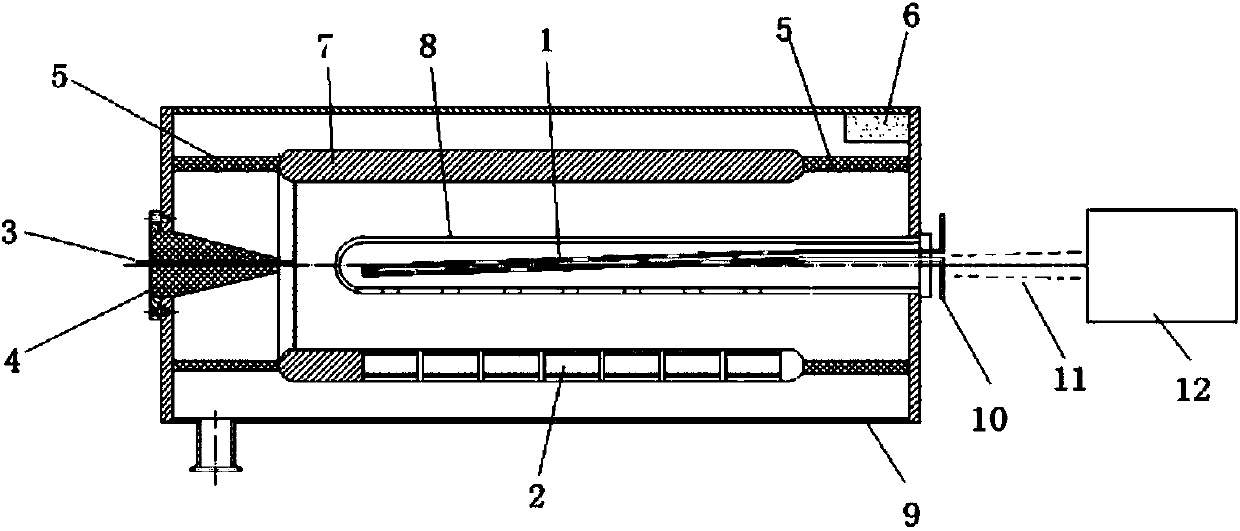

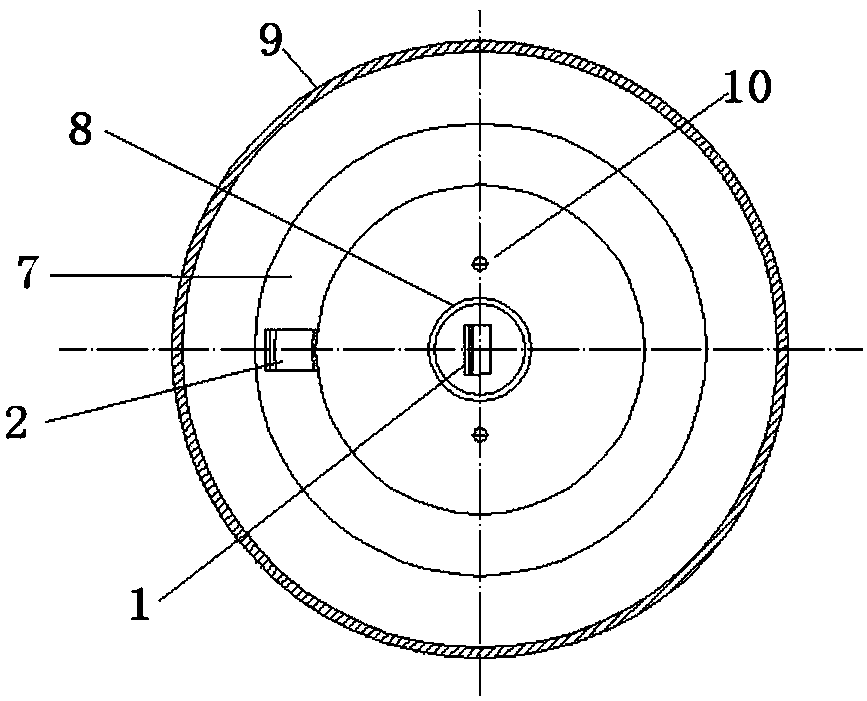

[0035] Such as figure 1 with figure 2 The given long directional target is a single-sided target. In the length direction, the target surface has an inclination angle greater than 0 degrees and less than 5 degrees, and the projection density is evenly distributed. The specific tilt angle is determined by the length of the long directional target and the required directional projection area .

[0036] The ion beam energy is 175keV, the current is 100mA, the target length is 500mm, the target area is 500mm×10mm, the projection area of the neutron beam extraction direction is 10×10mm, and the power density of the target surface is 350W / cm 2 The heat flux density. The line density of the ion source is 2mA / cm.

[0037] Use pure titanium target with a thickness of 1mm and a temperature rise of about 200 degrees; use a copper-based titanium-plated target with a temperature rise of about 10 degrees; use Al 2 O 3 Ceramic target, temperature rise is about 170 degrees, Al 2 O 3 The ceramic...

Embodiment 2

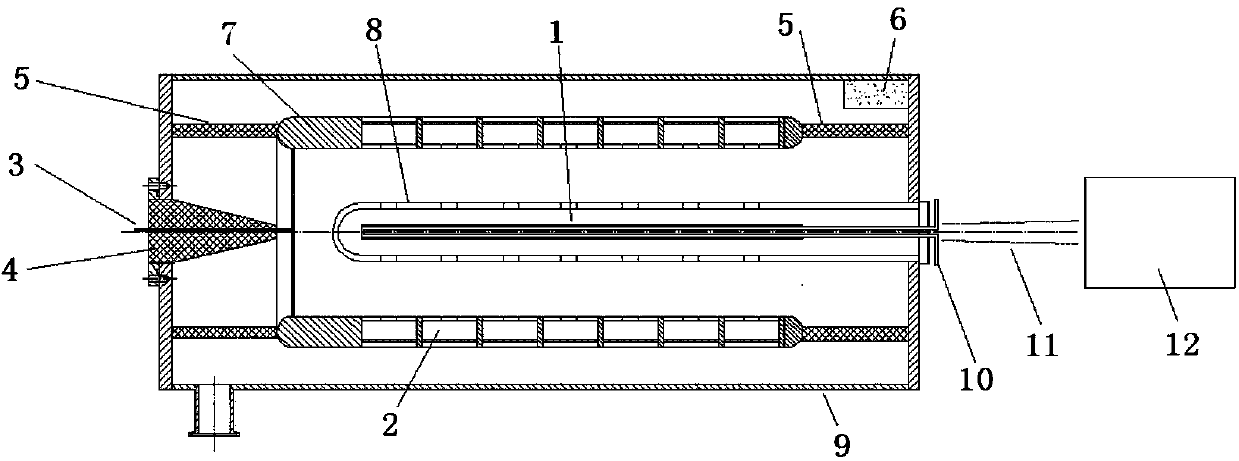

[0041] Such as image 3 with Figure 4 The given long directional target is a cylindrical target. Change the shape of the bombardment area of the cylindrical target so that the bombarded surface of the cylindrical target is inclined in the exit direction to form a cone. Then the projection distribution of the exit surface is a circular ring, cone The inclination angle of the conical surface is set according to the required projection shape and size. Less than 2 Place 10 rectangular Penning ion sources evenly on the circumference of the cylindrical electrode.

[0042] The ion beam energy is 175keV, the current is 300mA, the target length is 500mm, the area is 500mm×30mm, the projection area of the neutron beam extraction direction is in the circle of 10mm in diameter, and the power density of the target surface is 350W / cm 2 The heat flux density. The line density of the ion source is 6mA / cm, and the line density of each ion source is 0.6mA / cm.

[0043] A pure titanium target i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com