High-efficiency dynamic mixing device with multiple partition cavities

A compartmentalized and high-efficiency technology, applied in mixers, mixers, mixing methods and other directions with a rotating stirring device, can solve the problems of high flow requirements, large pipe arrangement space, and difficult cleaning of the pipe process. The effect of short circuit, saving equipment space, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

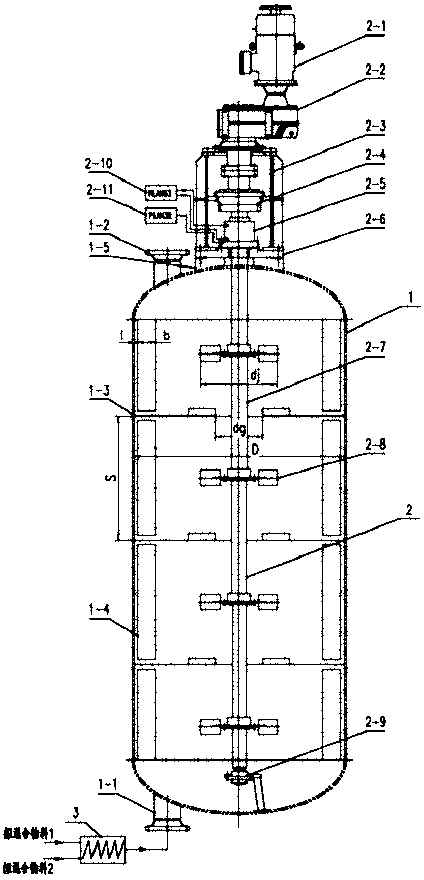

[0032] In one embodiment, as figure 1 Among them, a high-efficiency multi-chamber dynamic mixing device mainly includes a dynamic mixing tank body 1, a dynamic mixing agitator 2 and a pre-mixer 3.

[0033] The material inlet 1-1 is set at the lower head of the dynamic mixing kettle body 1, and the quantity is 1. The two liquids to be mixed in the dynamic mixing kettle body are premixed through the static pre-mixer 3 outside the dynamic mixing kettle body. After forming a liquid flow, it enters the dynamic mixing tank body 1 from the material inlet 1-1. The material outlet 1-2 is set at the upper head of the dynamic mixing kettle body.

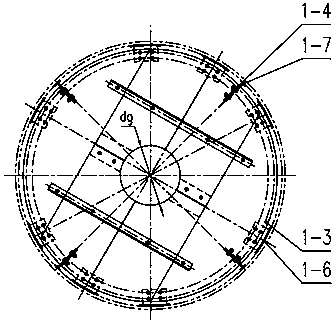

[0034] figure 2 Among them, the inner wall of the dynamic mixing kettle body 1 is welded with a compartment plate support 1-6 and a baffle plate support 1-7. The compartment plate 1-3 adopts a block detachable structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com