Method for calculating powder output of double-inlet and double-outlet coal mill

A double-input, double-outlet, calculation method technology, applied in the direction of grain processing, etc., can solve problems such as large fluctuations in material level, deviation of pulverized coal, and clogging of separators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

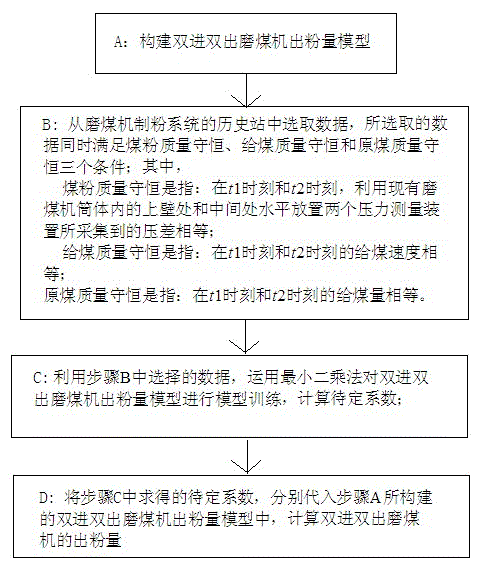

[0032] Such as figure 1 As shown, the calculation method of the powder output of the double-inlet and double-outlet pulverizer of the present invention comprises the following steps:

[0033] A: Constructing a pulverized output model of a double-inlet and double-outlet pulverizer

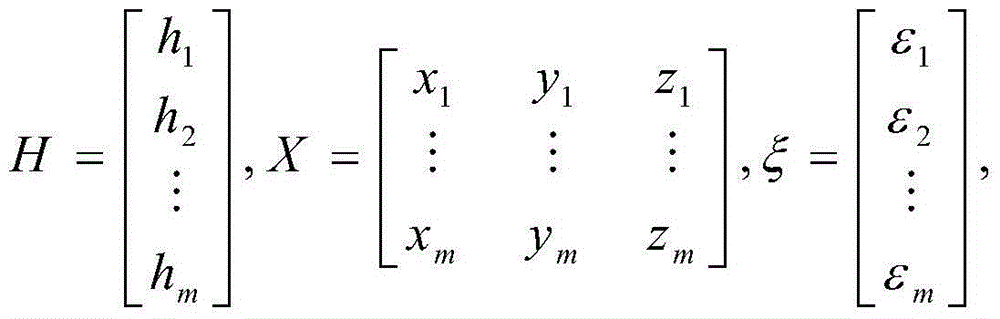

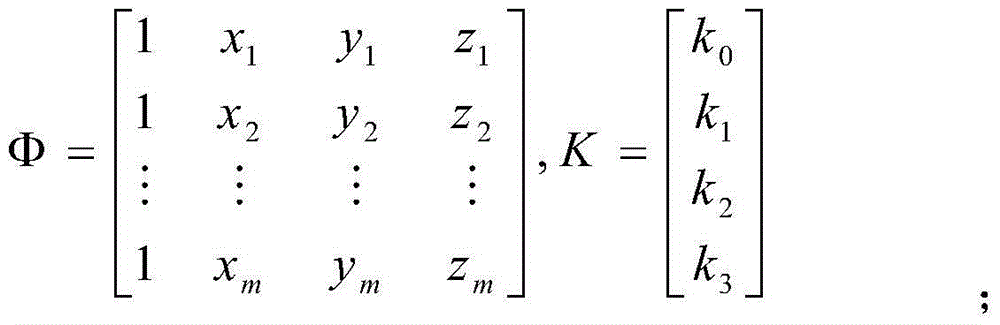

[0034] Among them, M out (t) is the powder output of the coal mill at time t, P 2 is the load wind pressure, is the load damper opening, k 0 、k 1 、k 2 、k 3 are undetermined coefficients;

[0035] Constructing the powder output model of double-inlet and double-outlet pulverizer The calculation is mainly carried out through the following steps:

[0036] 1. Firstly carry out load wind mass flow rate Q m Estimates for :

[0037] The load air volume flow Q is related to the wind speed ν flowing through the load air duct and the cross-sectional area S of the air duct, namely

[0038] Q=Sν (1)

[0039] Load air volume flow Q and load air mass flow Q m satisfy the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com