Plant layout structure and plant layout method of multi-stage tables for sorting, concentrate filtering and conveying

A plant and concentrate technology, applied in the direction of solid separation, etc., can solve the problems of large height difference and floor area of the plant, small processing capacity of the shaking table, increased operating costs, etc., to save the height difference and floor area of the plant, reduce The effect of production cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

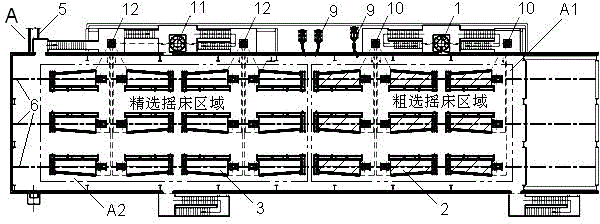

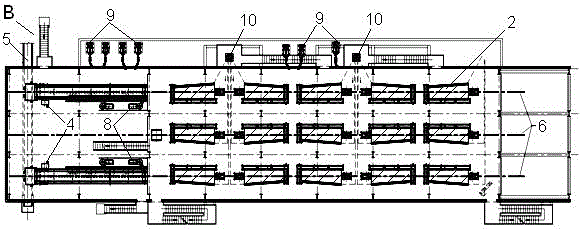

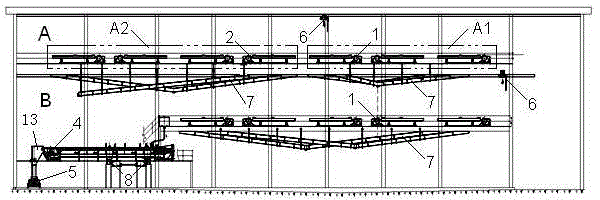

[0013] Example: The present invention is aimed at the configuration of the re-selection workshop with a scale of about 600 tons: the materials entering the shaker workshop are selected through the distributor 1 to the rougher shaker 2 for rough selection, and the products of the upper shaker pass through the conveying chute 7 and then enter the lower shaker through the pipeline. The shaker of the corresponding product of the bed is connected to the ore tank, the concentrate of the rougher shaker 2 is fed into the selection shaker 3 through the delivery pump 9, the concentrate of the selection shaker flows into the filter 4 for dehydration, and the filter cake enters the belt The conveyor 5 is transported to the product storehouse, and the filtrate enters the filtrate tank for collection and recycling.

[0014] The main equipment in the shaker separation and concentrate filtration workshop includes the first and second pulp distributors 1 and 11, rougher shaker 2, finer shaker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com