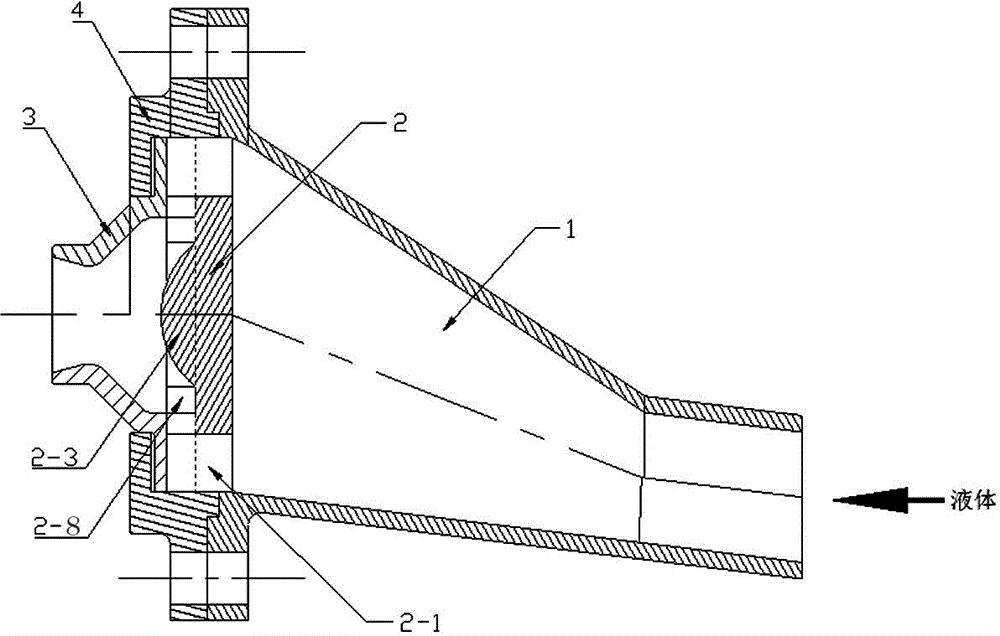

Anti-deposition pressure atomization nozzle

An atomizing nozzle and anti-deposition technology, which is applied to spray devices, spray devices, spray devices with movable outlets, etc., can solve the problems of large consumption of materials, unreasonable structure, difficult processing and manufacturing, etc. The effect of low loss and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0057] In specific implementation, the swirl vanes can have various forms and structures. Take the following implementations as examples:

example 1

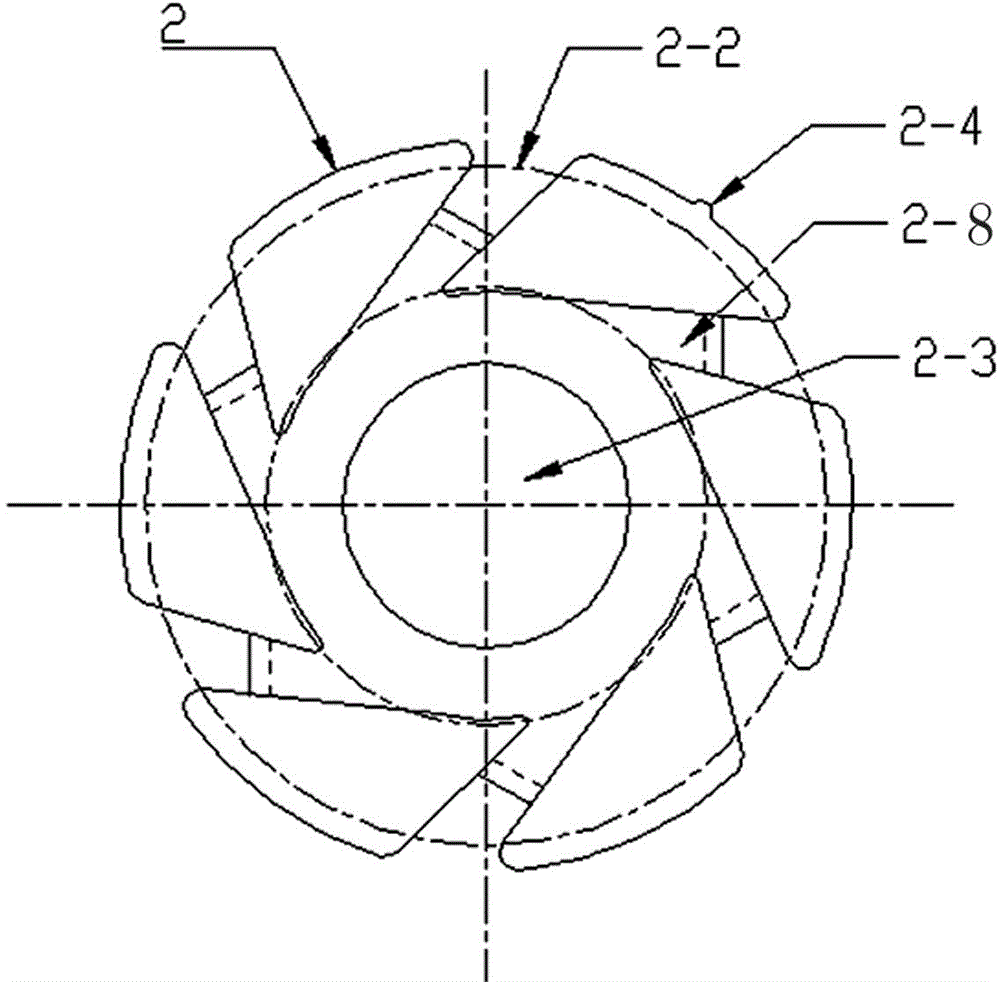

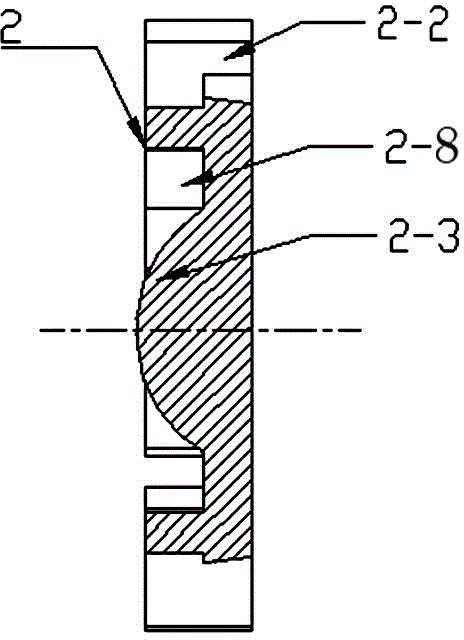

[0059] like figure 2 , image 3 , Figure 4 The circular swirl sheet shown has a circular groove in the center of the side plate facing the swirl atomization chamber, and six tangential grooves are evenly distributed along the periphery of the circular groove 2 -8, the tangential groove 2-8 communicates with the circular groove. The central portion of the circular groove is provided with an arc-shaped central protrusion 2-3.

[0060] The outer edge of the tangential groove 2-2 is dug to the other side of the swirl plate 2 to form the liquid distribution groove 2-2. like image 3 As shown, the wall surface of the liquid distribution tank 2-2 is inclined toward the direction of the water inlet chamber 1, and is in the shape of a cone, and the horizontal inclination angle of the wall surface is ≥3°.

[0061] After the pressure liquid enters the tangential groove 2-8 from the liquid distribution groove 2-2, under the action of the tangential groove 2-8, it forms a swirl flow...

example 2

[0064] like Figure 5 , Figure 6 , Figure 7 As shown in a circular swirl sheet, an annular groove is provided on the center of the side plate facing the swirl atomization chamber, and six tangential grooves 2-8 are evenly distributed along the circumference. The inner circle of the groove protrudes upwards to form an arc-shaped central protrusion 2-3, and the tangential groove 2-8 is located on the periphery of the central protrusion 2-3 and communicates with the annular groove.

[0065] The outer side of the tangential groove 2-2 is provided with a liquid distribution hole 2-1 penetrating to the other side of the swirl sheet 2. like Figure 6 As shown, the wall surface of the liquid distributing hole 2-1 is inclined toward the water inlet chamber 1, and is in the shape of a truncated cone, with a cone angle ≥ 6°.

[0066] In the above embodiment, the central protrusion 2-3 of the swirl plate 2 can be integrally formed with the swirl plate body, or can be processed separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com