Livestock and poultry harmless intelligent processor

A processor and intelligent technology, applied in the field of sick and dead livestock and poultry treatment, can solve the problems of waste gas treatment effect, disease transmission and environmental pollution, low decomposition efficiency, etc., and achieve the effect of improving efficiency and improving chemical production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

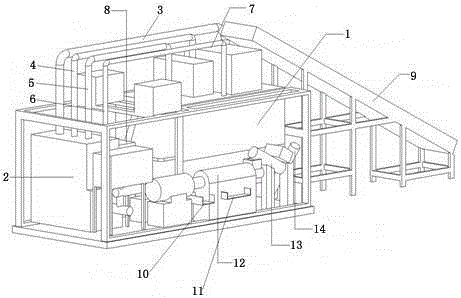

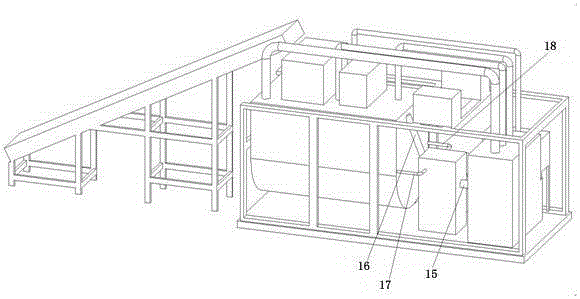

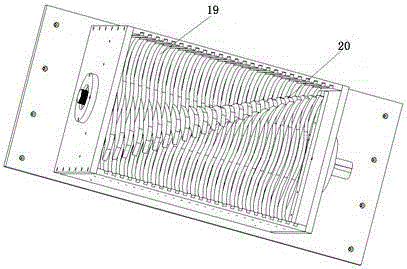

[0019] Such as Figure 1 to Figure 3 As shown, a harmless intelligent processing machine for livestock and poultry according to the present invention includes a waste decomposition device 7, which is connected to a waste lifting and conveying device 9, and a chemical system is arranged directly below the waste decomposition device 7. Tank device 1, the lower part of the chemical tank device 1 is provided with a grease refining and separation device, and the side of the chemical tank device 1 is connected to the hot blast stove device 2 and the medium oil heating device 8. Waste decomposition device 7 is made of fixed knife group 19 and movable knife group 20, and fixed knife group 19 is made up of several W-shaped fixed knives identical in shape, and movable knife group 20 is made up of some movable knives, and every movable knife is made up of two The knife blades ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com