Vacuum self-consuming furnace crystallizer welded cylinder producing process and welding assistive device

A vacuum consumable furnace and crystallizer technology, which is applied to other manufacturing equipment/tools, welding equipment, manufacturing tools, etc., can solve the problems of complex process, high price, high production cost, etc., achieve structural strength and precision reduction, and reduce production Cost, the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

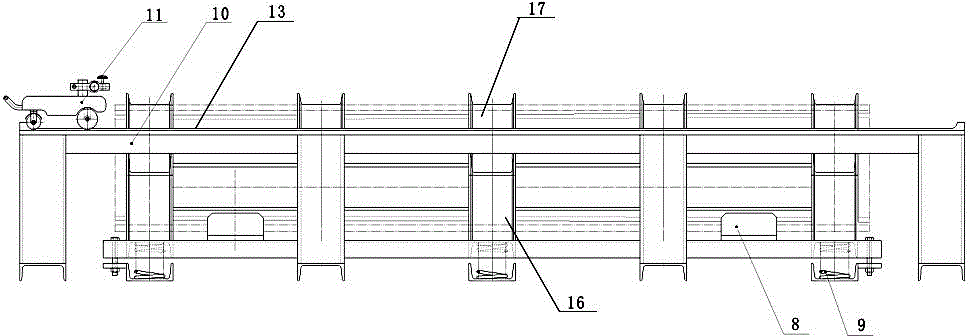

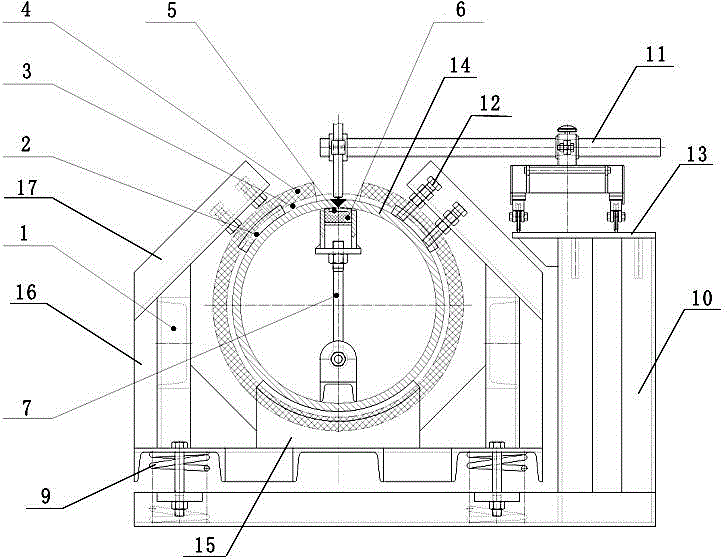

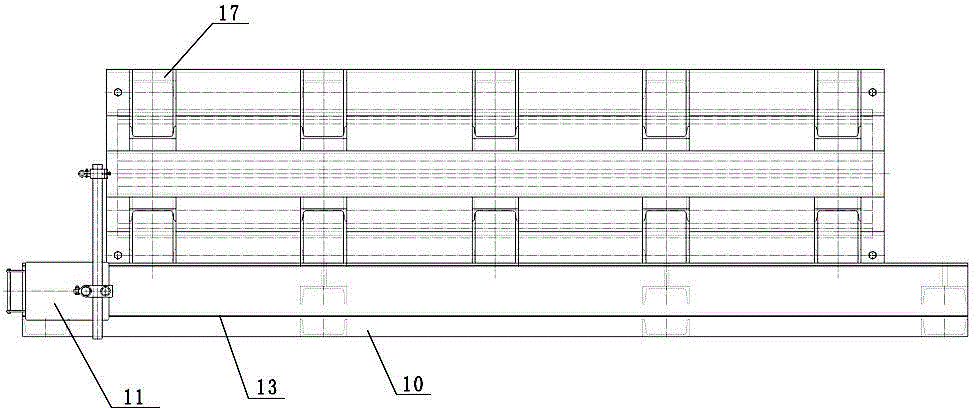

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[0023] The present invention provides a vacuum consumable furnace crystallizer welding cylinder manufacturing process, the main steps are as follows:

[0024] Simulate the production of a welding test plate with the same welding conditions as the cylinder body. The main considerations include material, welding temperature, heat treatment, heat preservation conditions, etc. The test plate is subjected to a tensile test under the second-level weld The reduction of the joint strength determines the thickness of the plate required for the cylinder; the plate is preferably T2 or TP2 copper plate, which can meet the specific needs of special steel smelting in vacuum consumable furnaces;

[0025] The selected boards are blanked at one time, and the trimming process is carried out on the blanked cylinder boards, that is, planin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com