Quick keyway positioning and clamping device

A positioning and clamping, fast technology, applied in positioning device, clamping, supporting and other directions, can solve the problems of low work efficiency, difficult to hit the process requirements, complex process, etc., to achieve high parallelism and symmetry of the workpiece, upper and lower workpieces. Convenient, quick and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

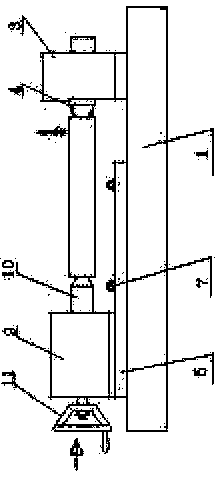

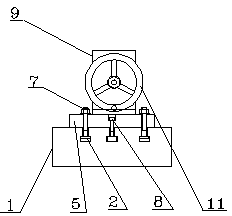

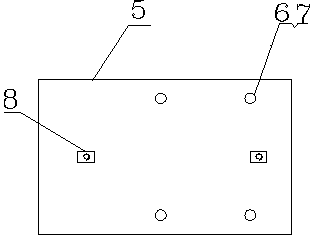

[0011] see Figure 2-4 , the keyway fast positioning and clamping device of the present invention has a milling machine worktable 1, three T-shaped grooves 2 are arranged transversely on the upper, middle and lower parts of the milling machine workbench respectively, and the right side of the milling machine workbench 1 passes T-shaped bolts 7 and the milling machine workbench The T-shaped groove 2 on the top is equipped with a right thimble seat 3, and the right thimble seat 3 is provided with a claw thimble 4, and a number of through holes 6 are respectively opened on the upper, middle and lower parts of a bottom plate 5, and the through holes 6 are connected with the milling machine workbench. The three T-shaped slots 2 correspond to each other. The bottom plate is installed on the left side of the milling machine table through the T-shaped bolts passing through the through holes of the bottom plate and the T-shaped slots on the milling machine table. The T-shaped bolts in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com