Butt joint system of train and platform passageway

A channel and train technology, which is applied in the field of permanent magnet drive wheel-rail maglev vehicle system, can solve the problems of rising ticket prices, impassability of wheel-rail trains, and increased air resistance, so as to prevent loss of items, high safety protection, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention is described in further detail now in conjunction with accompanying drawing.

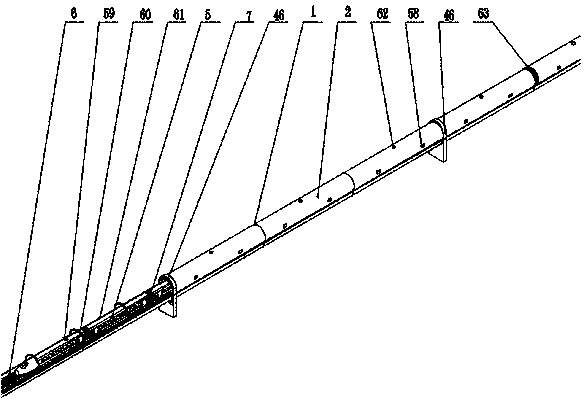

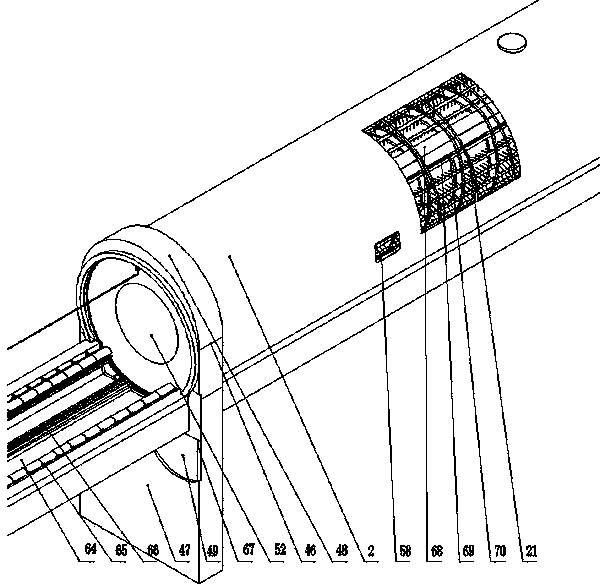

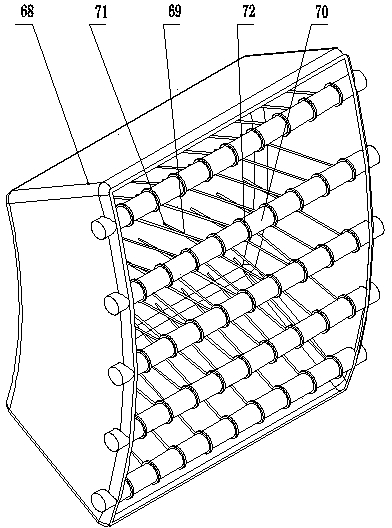

[0094] As shown in Figure 1 and Figure 2, the low-pressure pipeline 1 of the present invention is pumped into a low-pressure state under the seal of the external sealing cover 2, and the pressure in the pipeline is usually 0.1-0.22 times the standard atmospheric pressure. The low-pressure pipeline 1 is provided with a light-transmitting window 58 and a safety vent plug 62, and a pipeline expansion joint 63 is provided at a certain distance to avoid the influence of internal stress caused by thermal expansion and contraction of the pipeline caused by weather changes. A pipeline isolation gate 46 is set at the junction of the low-pressure pipeline 1 and the outside atmosphere, and the transition pipeline that can change the pressure is sealed between the two isolation gates 46. A filling air bag 68 is arranged around the pipe wall of the transition pipeline, and the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com