Energy-saving processing method for wastewater generated during liquor brewing process

A technology of brewing wastewater and treatment methods, which is applied in the fields of wastewater treatment and food wastewater treatment, can solve problems such as uneven aeration, high power, and insufficient aeration volume, and achieve low-consumption and high-efficiency removal, saving input and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

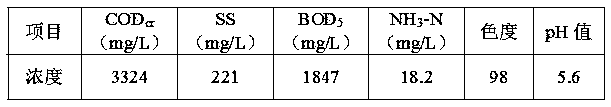

[0014] In a liquor production enterprise, in addition to production wastewater, the wastewater produced also includes some domestic wastewater in the factory area, with a volume of wastewater of 350 m 3 / d, raw water quality indicators are shown in Table 1.

[0015] Table 1 Wastewater quality indicators (average value) of a liquor production enterprise

[0016]

[0017] An energy-saving treatment method for liquor brewing wastewater, the specific steps are as follows:

[0018] (1) The waste water first flows through the mechanical grille, removes coarse particles and floating objects, and then flows into the sump, and then lifts it to the comprehensive pool by the first-stage lift pump;

[0019] (2) The waste water enters the comprehensive tank. In the sedimentation adjustment area, the scum in the water is scraped by the scraper to the sand filter tank. The sand filter tank is equipped with filter sand. After sand filtration, the filtrate is returned to the adjustment tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com