Preparation method for bisphenol fluorene

A technology of bisphenol fluorene and fluorenone, which is applied in the field of preparation of bisphenol fluorene, can solve the problems of co-catalysts with foul odor, air pollution, and worker poisoning, and achieve the effects of good product quality, simple process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

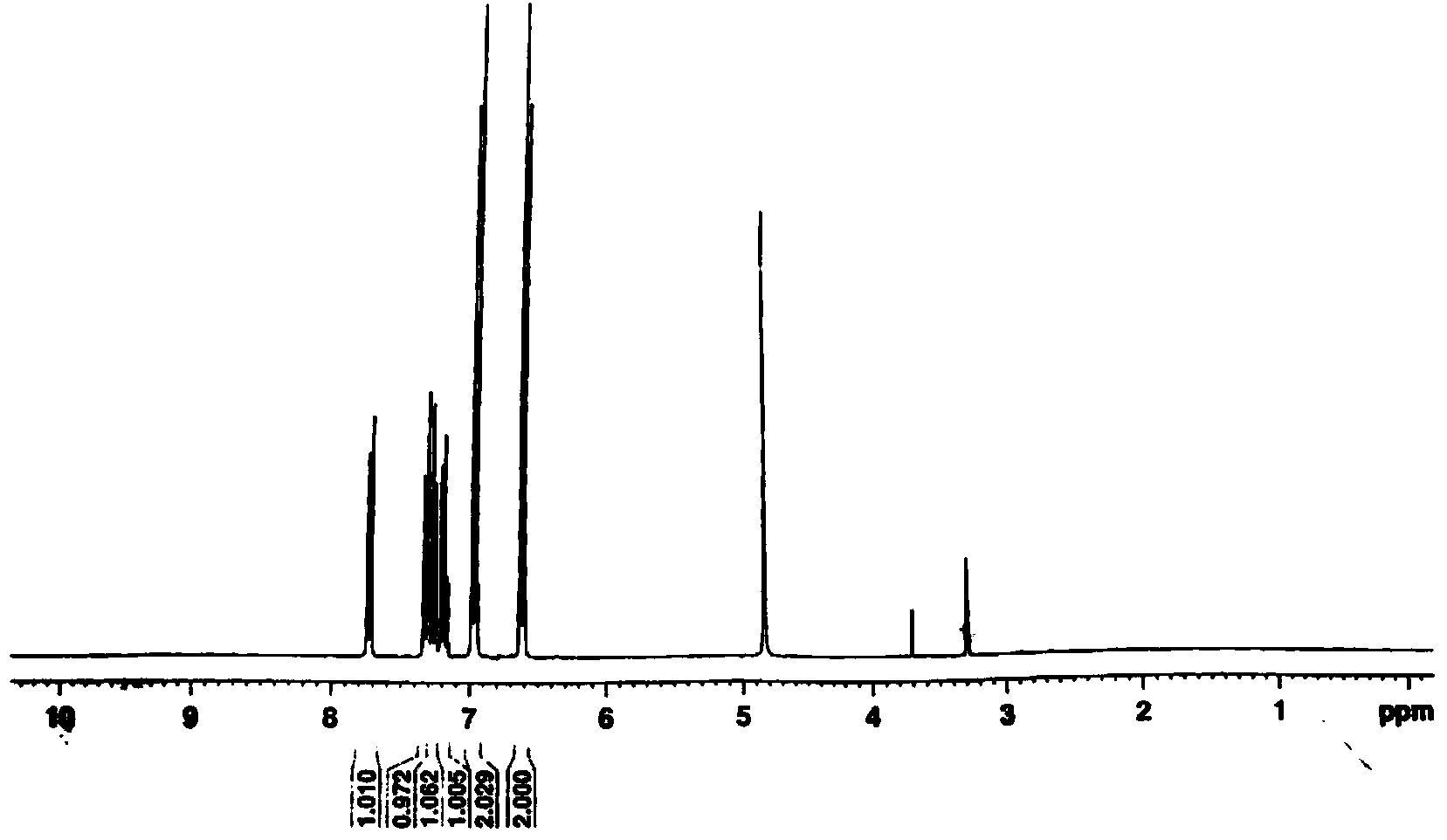

[0011] Add 100g of 9-fluorenone, 350g of phenol, and 0.5g of cysteamine into a 1000ml four-neck flask, heat up to 50°C under stirring and dissolve completely, cool to below 30°C, slowly add 28g of 98% sulfuric acid dropwise, and heat up to 55°C after dropping Keep stirring at ℃ for 6 hours, add 150ml of water, neutralize with liquid caustic soda to pH 6-7, separate the desalinated layer, recover phenol from the oil layer under reduced pressure, and recrystallize with ethanol and water mixed solvent to obtain white crystals, which can be obtained after drying. Phenolfluorene 175g, yield 90%, content 98.9%. The final product 1 HNMR spectrum as figure 1 Shown, show that the product finally obtained by this method is bisphenol fluorene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com