Comprehensive processing system for straw gasification

A comprehensive treatment of straw, applied in the field of straw gasification comprehensive treatment system, can solve the problems of polluted air, ineffective utilization, harmful to human health, etc., and achieve the effects of avoiding waste, light weight and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Accompanying drawing is a kind of specific embodiment of the present invention.

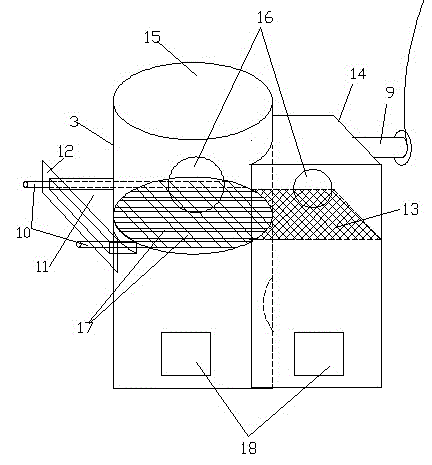

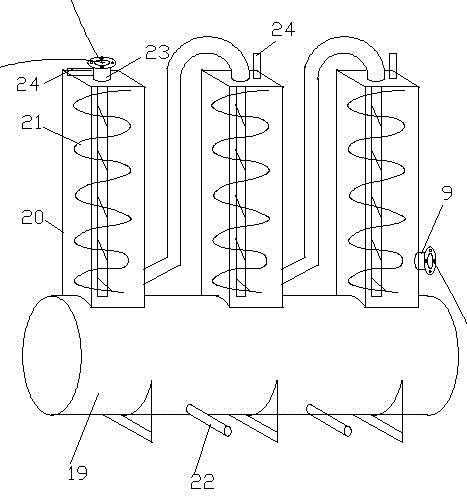

[0021] The straw gasification comprehensive treatment system of the present invention includes sequentially connected water-washing tar processors, filter-type tar processors, touch-type tar processors, fine filter-type tar processors, and the input ends of the water-washing tar processors are connected in parallel with charcoal. Barn and straw gasifier unit, the straw gasifier unit is detachably installed with circulating water cooling furnace grate; between two adjacent equipment, the gas outlet of the former is connected to the air inlet of the latter.

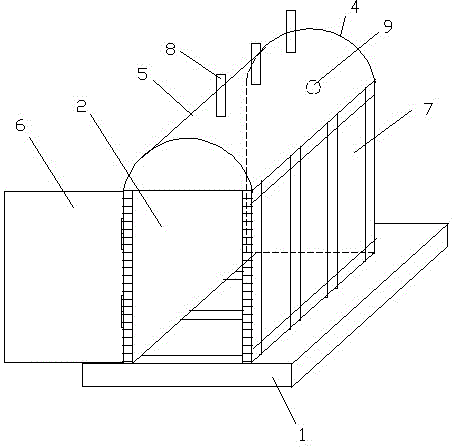

[0022] The charcoal grilling room includes a room built on the foundation 1, the room includes a left wall 2, a right wall, a rear wall 4 and a roof 5 connected to each other, and a front door 6 for feeding and discharging materials is installed in front of the room. The body is made of refractory bricks, and the outside of the body is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com