Two-phase anaerobic fermentation method for biogas production

A technology for anaerobic fermentation and biogas production, applied in the fields of environmental engineering and energy, can solve the problems of complex process structure and operation, high requirements for personnel and equipment, low gas production efficiency, etc. The effect of shortening the hydrolysis acid production cycle and increasing the gas production of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

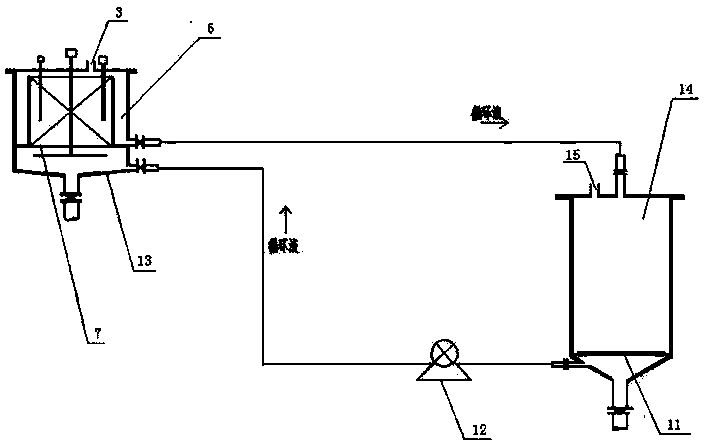

[0020] The present invention provides a two-phase anaerobic fermentation biogas production method using straw and kitchen waste as raw materials. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] This method adopts batch feeding, the substrate is placed in the hydrolysis acidification device 14, the fermentation liquid is sprayed on the substrate from top to bottom, and the organic matter in the substrate is produced under the action of the hydrolyzing bacteria group and the acid-producing bacteria group The eluate (the organic eluate is an organic acid such as acetic acid, propionic acid or butyric acid), and the gas generated at the same time escapes through the gas outlet 15, and the organic eluate is filtered by the perforated baffle 11, and is lifted by the lifting pump 12 along with the circulating liquid. Pump into the fermentation gas production device 13, after adjusting the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com