Method for rapidly producing acid and cooperatively producing gas through dry-wet coupling anaerobic fermentation

An anaerobic fermentation, dry-wet coupling technology, used in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of high organic load, difficult mass transfer, heat transfer, affecting the gas production efficiency of the system, etc., to improve the degradation rate. degree, improve gas production efficiency, and avoid the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

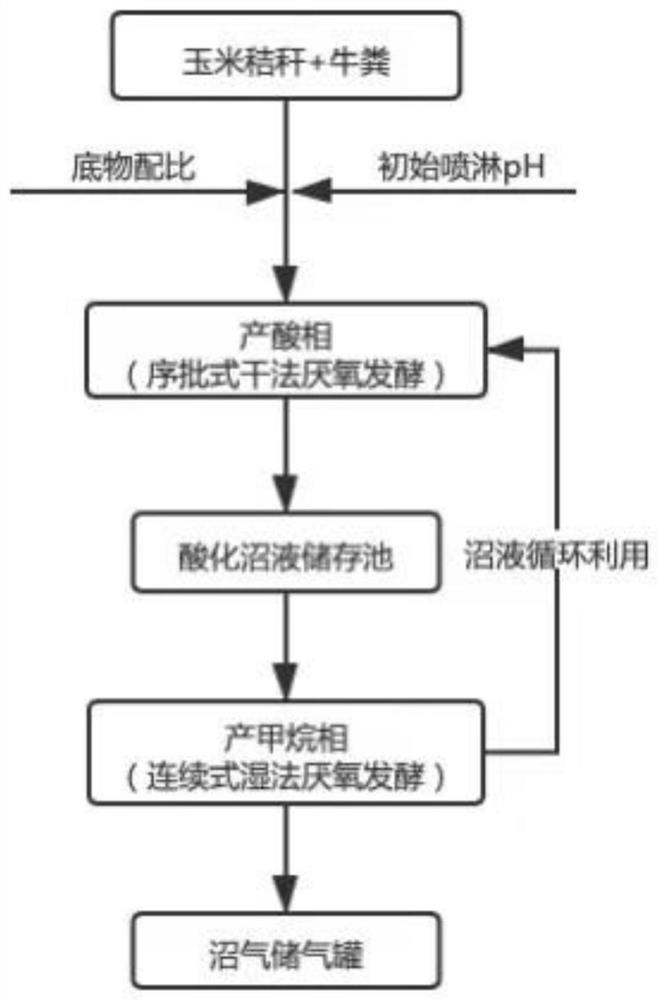

[0033] Method for solving rapid acid coating gasification gas in dry wet coupled anureoxic fermentation (see figure 1 ), Consisting of the following steps:

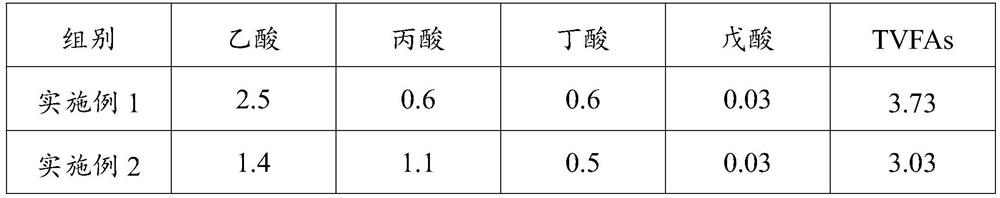

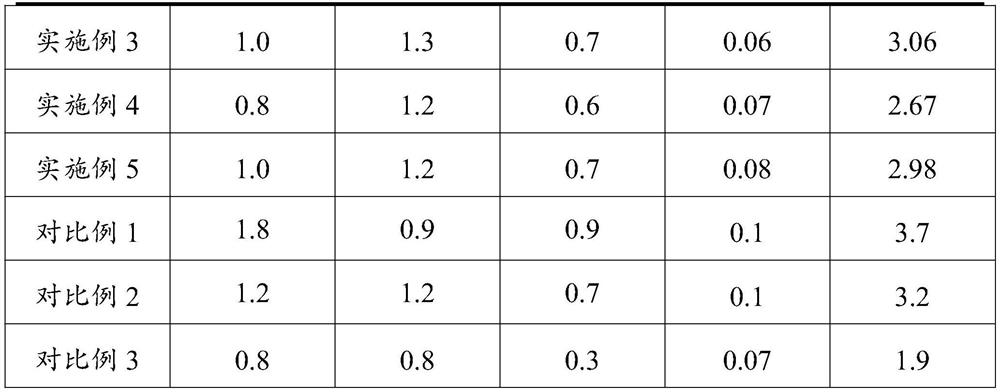

[0034] 1) Mix the corn stalk and cow dung mixed into fermented raw materials, regulating the mass ratio of straw and cow dung as 7: 3 (carbon nitrogen ratio (25 ± 0.44): 1); adjusted foreign biogasic acid in 0.5 mol / L hydrochloric acid ( The pH of the three-river bread farm culture, pH is 8.0), the pH of 5.5, the amount of inoculation is 1 l / time (the amount of foreign biogas is inoculated is 30 wt.%) Of the fermentation material, 4 times / day In addition to the external biogas solution after adjusting the pH, the pre-batch dry anaerobic fermentation is performed as a 5L perfigenated bed reactor as a dry wet coupling anureoxic fermentation. The TS (Rate) The hydrolyzate process is completed under 25% of the hydrolyzate process, and the acidified cycle is stored in the reservoir;

[0035] 2) Mix the biogaside in the reser...

Embodiment 2

[0037] A method similar to that of Example 1, which distinguishes the mass ratio of straw and cow dung in step 1) of 6: 4 (carbon nitrogen ratio (24 ± 0.14): 1).

Embodiment 3

[0039] A method in Example 1 a similar embodiment, except that the mass ratio of Step 1) in dung and straw is 5: 5 (ratio of carbon and nitrogen (21 ± 0.66): 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com