Precast bridge deck space steel pipe concrete truss composite beam and construction method

A technology of steel pipe concrete and steel pipe truss, which is applied in the direction of bridges, bridge parts, bridge construction, etc., and can solve problems such as shortening the construction period, unachievable construction methods, and increasing structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

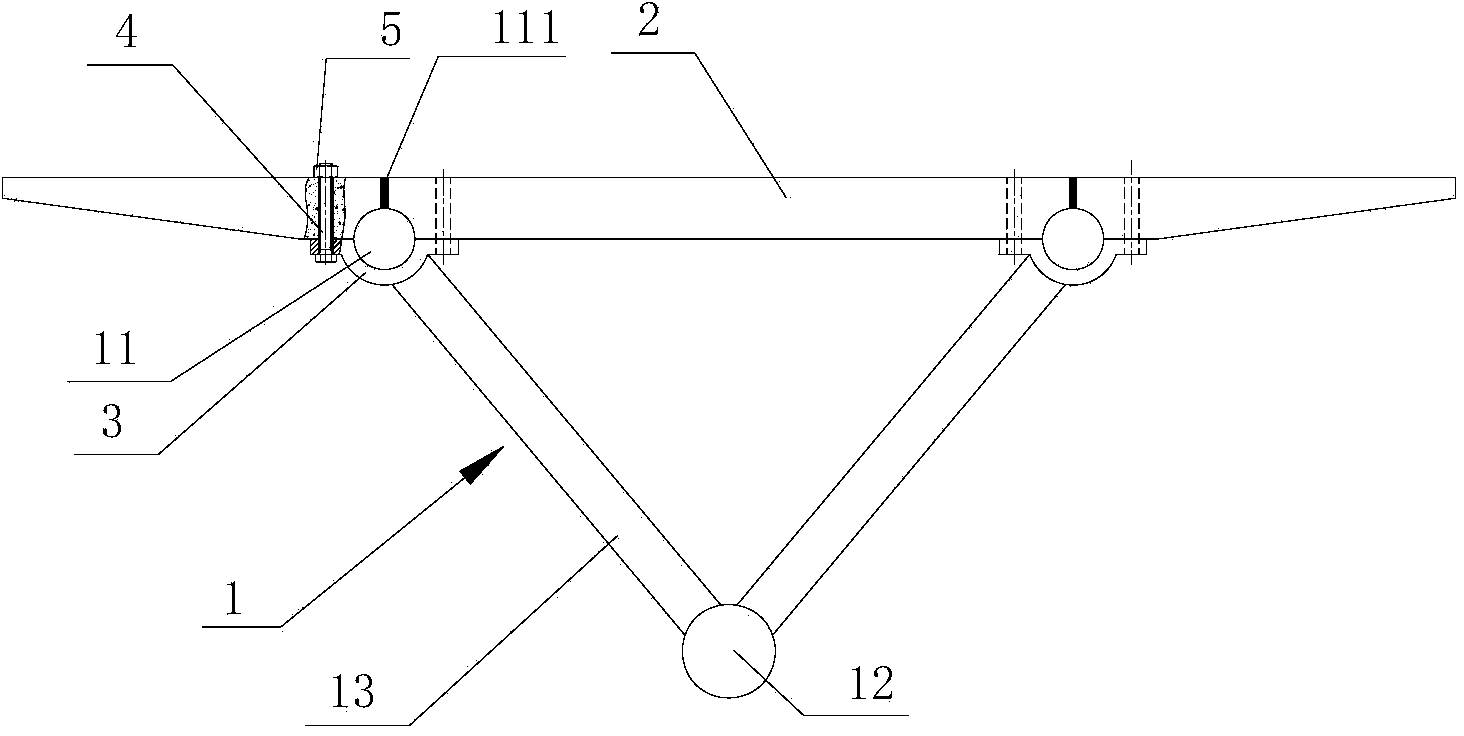

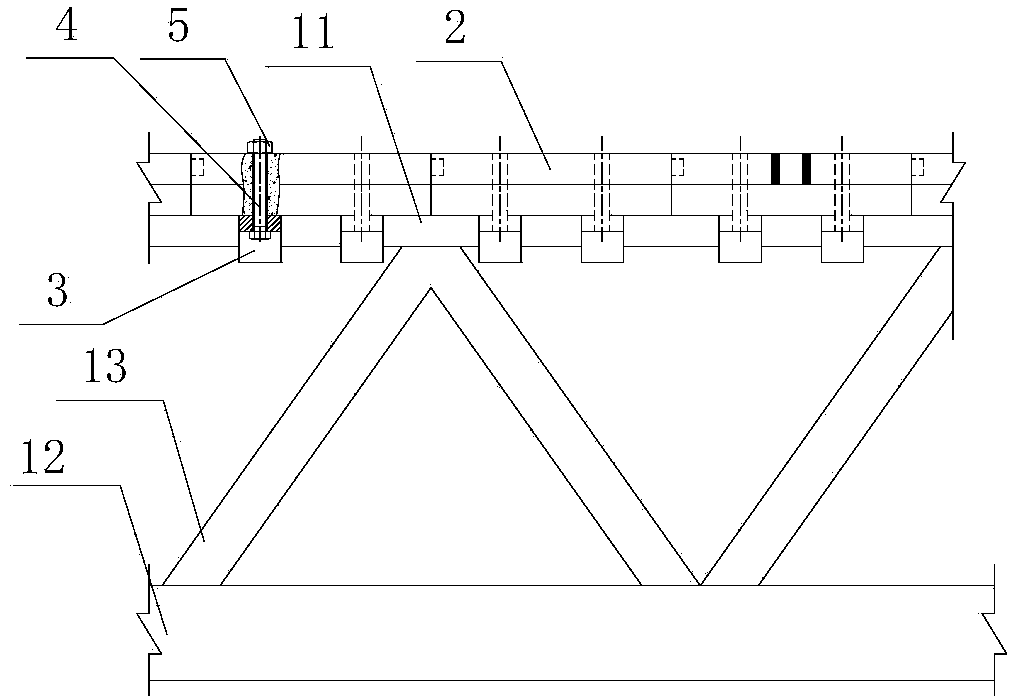

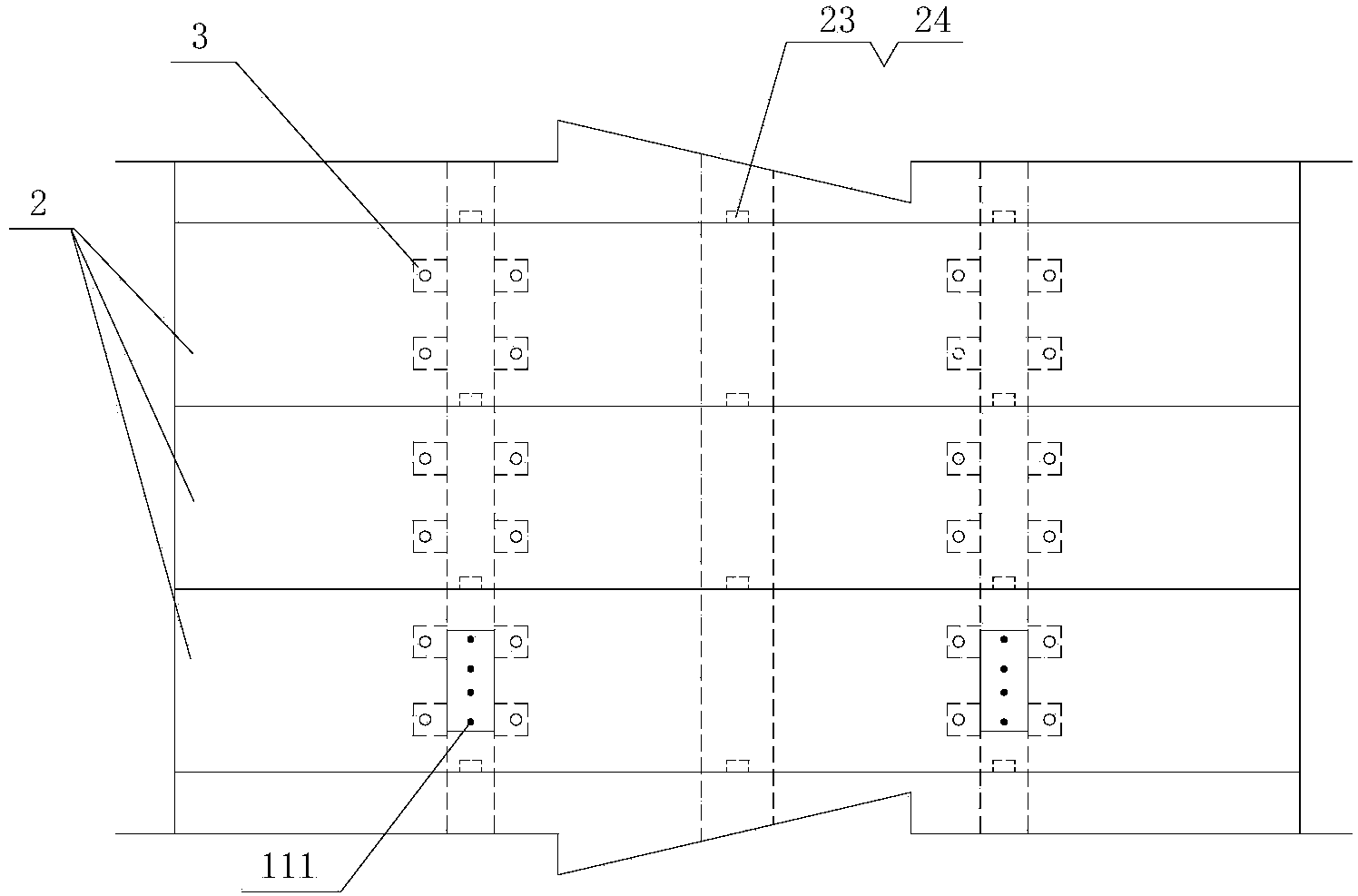

[0037] Prefabricated bridge deck space CFST truss composite beam, please refer to Figure 1-7 . Including the steel pipe truss 1, the steel pipe truss refers to the current technology, which includes two upper chord steel pipes 11, lower chord steel pipes 12 and web bars 13 connecting the upper and lower chord steel pipes. It also includes a plurality of independent bridge decks 2 sequentially laid on the upper part of the steel pipe truss along the longitudinal direction of the bridge. On the lower end surface of each bridge deck, there are two positioning grooves 21 that cooperate with the two upper chord steel pipes of the steel pipe truss one by one, and the upper half of the upper chord steel pipes form an arc surface contact with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com