Sterilization rubber floor

A rubber floor and rubber technology, applied in the direction of elastic floor, building, building structure, etc., can solve the problems that affect the health of users, produce a lot of bacteria on the surface, and unfavorable appearance, so as to reduce the cleaning workload, prevent bacteria, The effect that does not get dirty easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

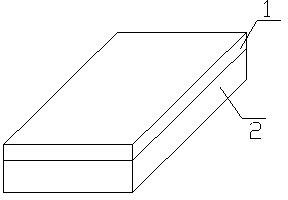

[0014] see figure 1 , provide a kind of sterilizing rubber floor, comprise top layer 1 and bottom layer 2, described top layer 1 and bottom layer 2 are mutually connected, and the thickness of described top layer 1 is 2.5mm, and the material of described top layer 1 is rubber, and the material of described rubber The composition is: in parts by mass, 100 parts of oil-extended styrene-butadiene rubber, 5 parts of zinc oxide, 3 parts of hard acid, 2 parts of sulfur, 40 parts of furnace carbon black N330, N-tert-butyl-2-benzothiazole 4 parts of hypoxanthamide, 3 parts of metrafenone, and 2 parts of pyrithrimol sulfonate.

Embodiment 2

[0016] Provide a kind of sterilization rubber floor, comprise top layer and bottom layer, described top layer and bottom layer are interconnected, the thickness of described top layer is 3mm, the material of described top layer is rubber, and the composition of described rubber is: by mass parts, 100 parts of oil-extended styrene-butadiene rubber, 8 parts of zinc oxide, 1 part of hard acid, 4 parts of sulfur, 65 parts of furnace carbon black N330, 1 part of N-tert-butyl-2-benzothiazole hypoxanthamide, benzothiazole 2 parts of ketone, 1 part of pyrimethrin sulfonate.

Embodiment 3

[0018] Provide a kind of sterilization rubber floor, comprise top layer and bottom layer, described top layer and bottom layer are interconnected, the thickness of described top layer is 2mm, the material of described top layer is rubber, and the composition of described rubber is: by mass parts, 100 parts of oil-extended styrene-butadiene rubber, 7 parts of zinc oxide, 2 parts of hard acid, 3 parts of sulfur, 55 parts of furnace carbon black N330, 2 parts of N-tert-butyl-2-benzothiazole hypoxanthamide, benzothiazole 2.5 parts of ketones, 1.5 parts of pyrimolsulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com