Structural dynamic design method for high-pressure rotor of aircraft engine

A technology for aero-engines and high-pressure rotors, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve problems such as limited application range and difficulty in applying aero-engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] This embodiment is a high-pressure rotor dynamics design method for a dual-rotor experimental device.

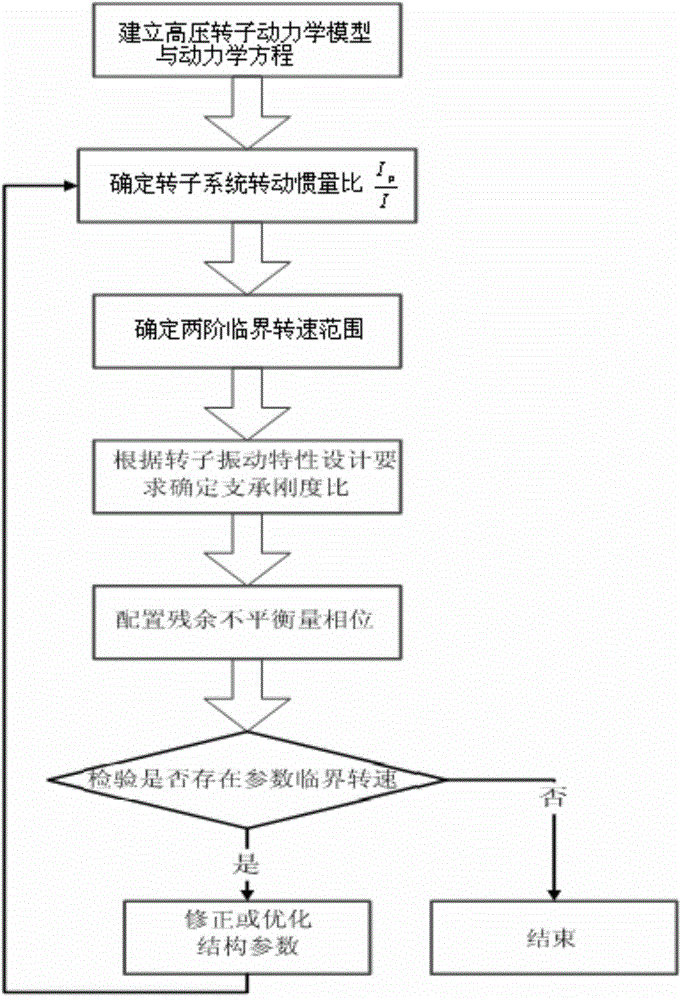

[0075] Step 1, establishing a high-pressure rotor dynamics model and dynamic equations.

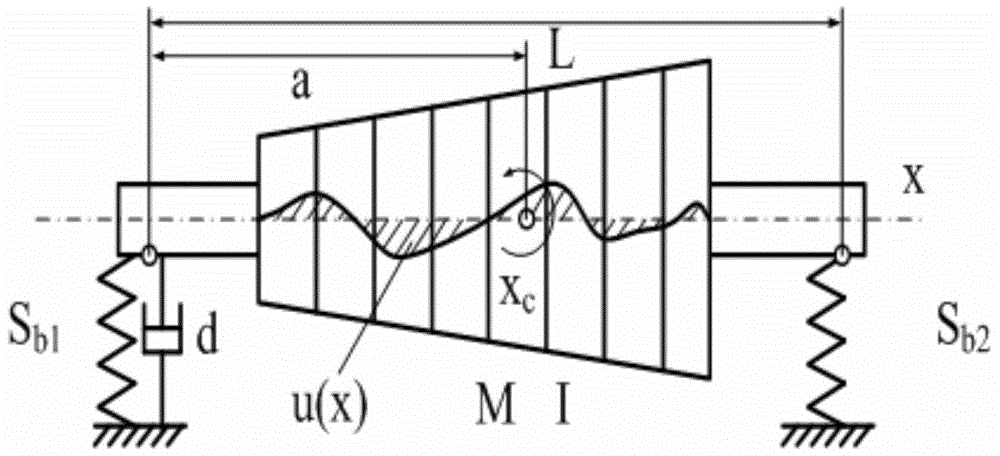

[0076] High pressure rotor model such as figure 2 shown. In this model, the high-pressure shaft and disc are supported between two elastic supports, and a damper is installed at the front fulcrum. In this model, the mass of the rotor is M; the pole moment of inertia is I p The distance between the center of gravity and the front fulcrum is a; the distance between the center of gravity and the rear fulcrum is b; the moment of inertia of the rotor around the center of gravity is I; the damping coefficient is d; two elastic supports, the stiffness of the front fulcrum support is S b1 , the support stiffness of the rear fulcrum is S b2 ; The distance between the two fulcrums is L; the position of the centroid is x c .

[0077] Firstly, the free vibration differential equation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com